Ultraphonic auxiliary micro-nano embossing forming device

A molding device and ultrasonic-assisted technology are applied in the field of nano-imprinting devices, which can solve the problems of easy destruction of micro-nano scales, and achieve the effects of improving filling efficiency and avoiding wasted time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

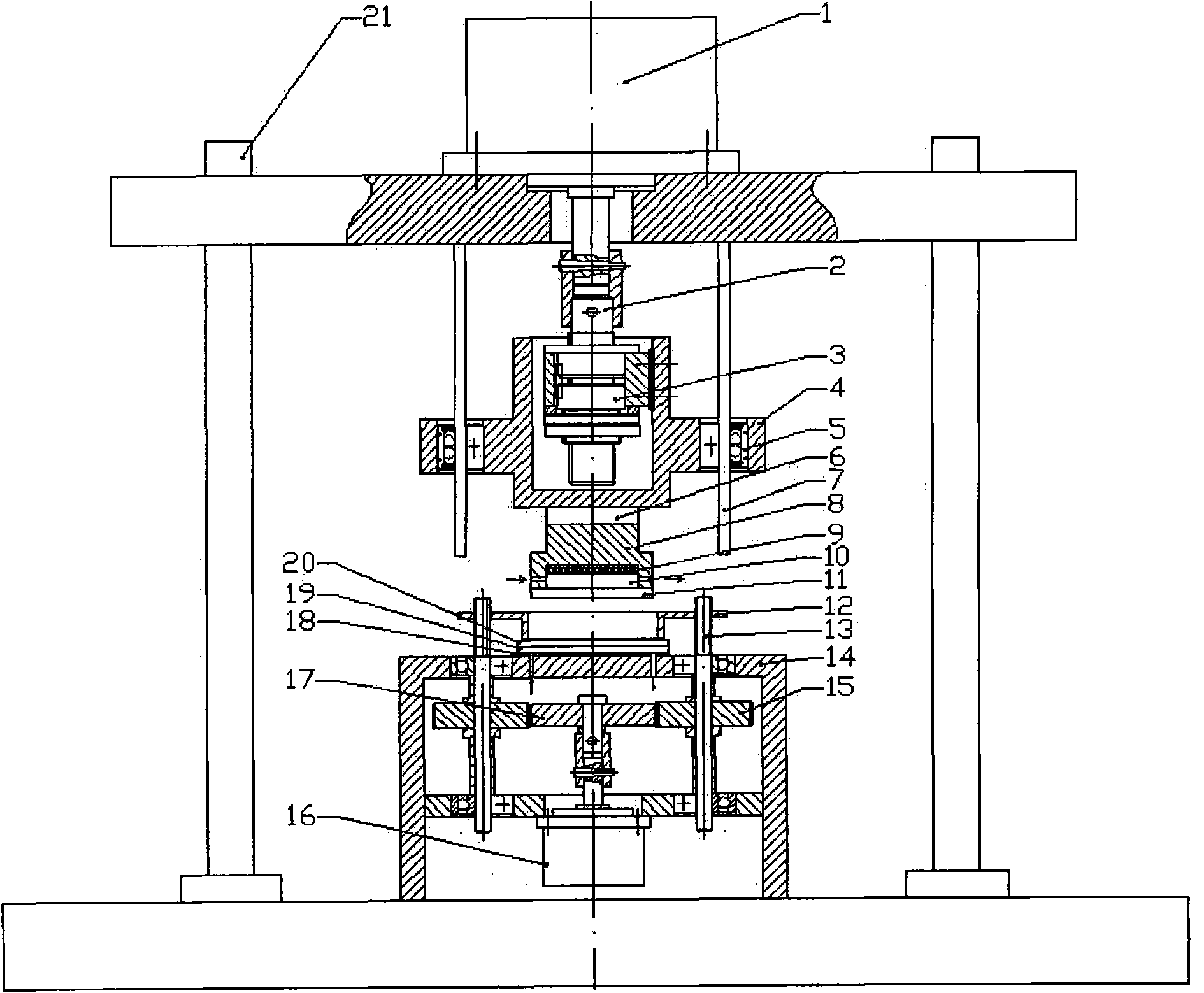

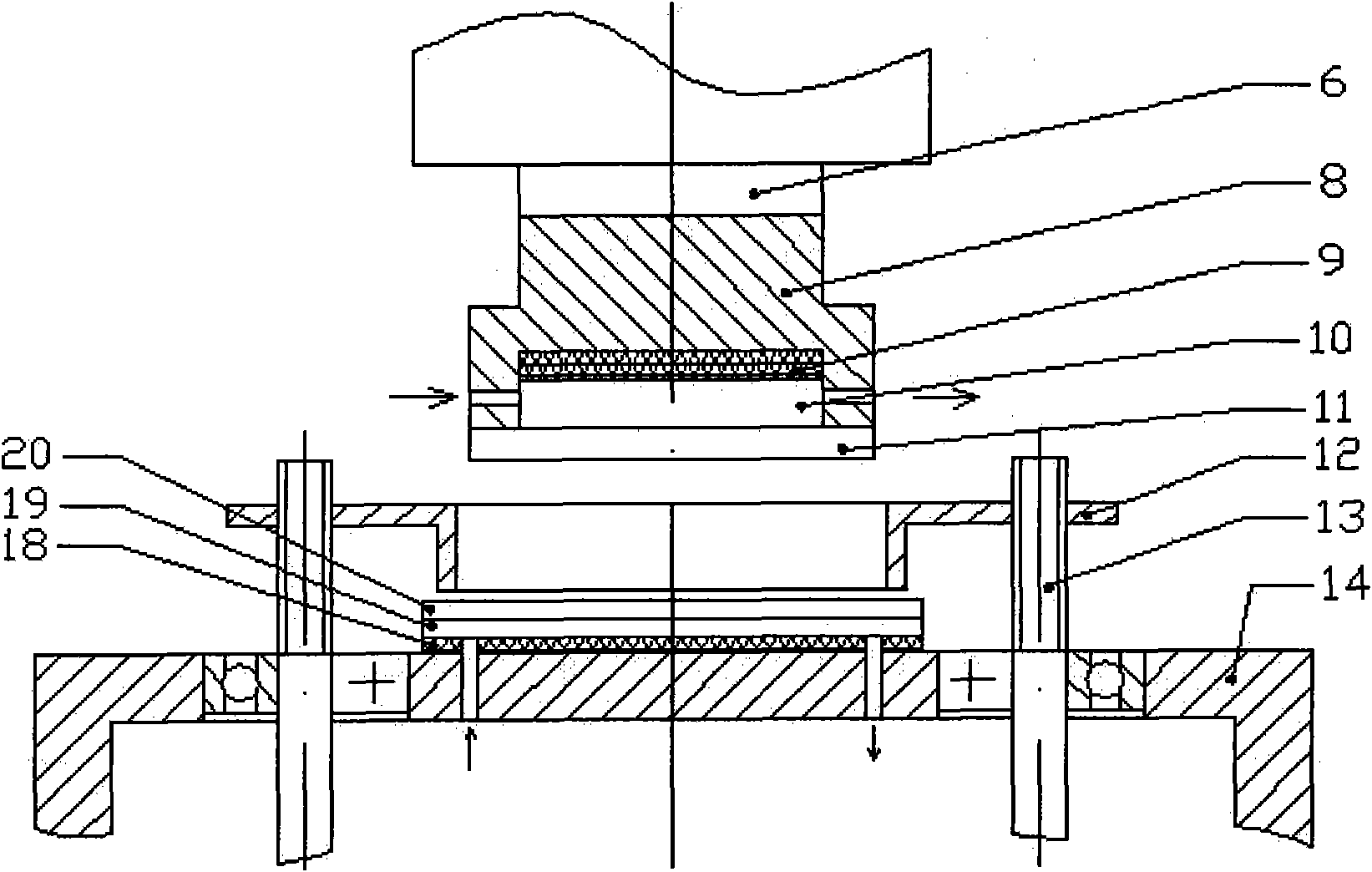

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] Such as figure 1 and figure 2 As shown, the torque motor 1 of the ultrasonic-assisted micro-nano imprint molding device of the present invention is installed on the support frame 21, and two guide shafts 7 are arranged under the beam of the support frame 21, and the two ends of the slider 4 pass through the linear bearing 5 and the guide shaft 7. Connected, can make relative linear movement along guide shaft 7.

[0024] The slider 4 is fixedly connected to the ball screw nut 3, the ball screw 2 is connected to the output shaft of the torque motor 1 through a coupling, the ball screw nut 3 cooperates with the ball screw 2, and the rotation of the torque motor 1 passes through the ball screw The rod nut 3 and the ball screw 2 drive the slider 4 to move linearly up and down.

[0025] The bottom of the slider 4 is fixedly connected with the ultrasonic generator 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com