Improved 800type silicon monocrystalline furnace thermal field system

A technology of silicon single crystal and furnace thermal field, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems affecting the utilization efficiency of silicon materials and the performance of finished solar cells, so as to improve efficiency and reduce unit energy Consumption, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

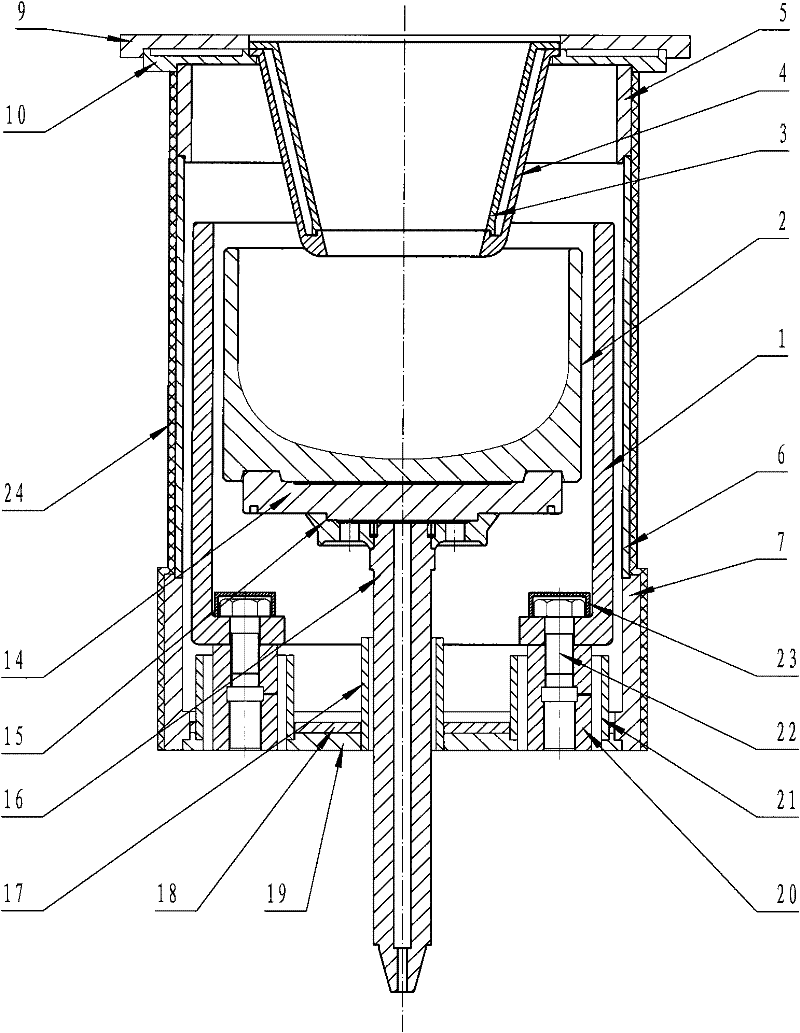

[0020] The original 800 type silicon single crystal furnace thermal field system such as figure 1 As shown, it includes a heater 1, a crucible 2, an inner guide cylinder 3, an outer guide cylinder 4, an upper insulation cylinder 5, a middle insulation cylinder 6, a lower insulation cylinder 7, an upper insulation cover 9, a lower insulation cover 10, an insulation Layer 24, crucible support 14, support rod shaft 16 and support rod shaft seat 15, support rod sheath 17, upper pressing piece 18, lower pressing piece 19, graphite electrode 20 and electrode sheath 21, electrode screw 22 and electrode screw cover twenty three. The dimensions of the main components of the original 800-type silicon single crystal furnace thermal field system are as follows: the outer diameter and height of the upper insulation cylinder 5 are 630mm×178mm, the outer diameter and height of the middle insulation cylinder 6 are 630mm×540mm, the outer diameter and height of the lower insulation cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com