Excavator

A technology for excavators and internal combustion engines, applied in the field of excavators, can solve problems such as lack of space, impractical maintenance, and inability to add, etc., and achieve the effect of large space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

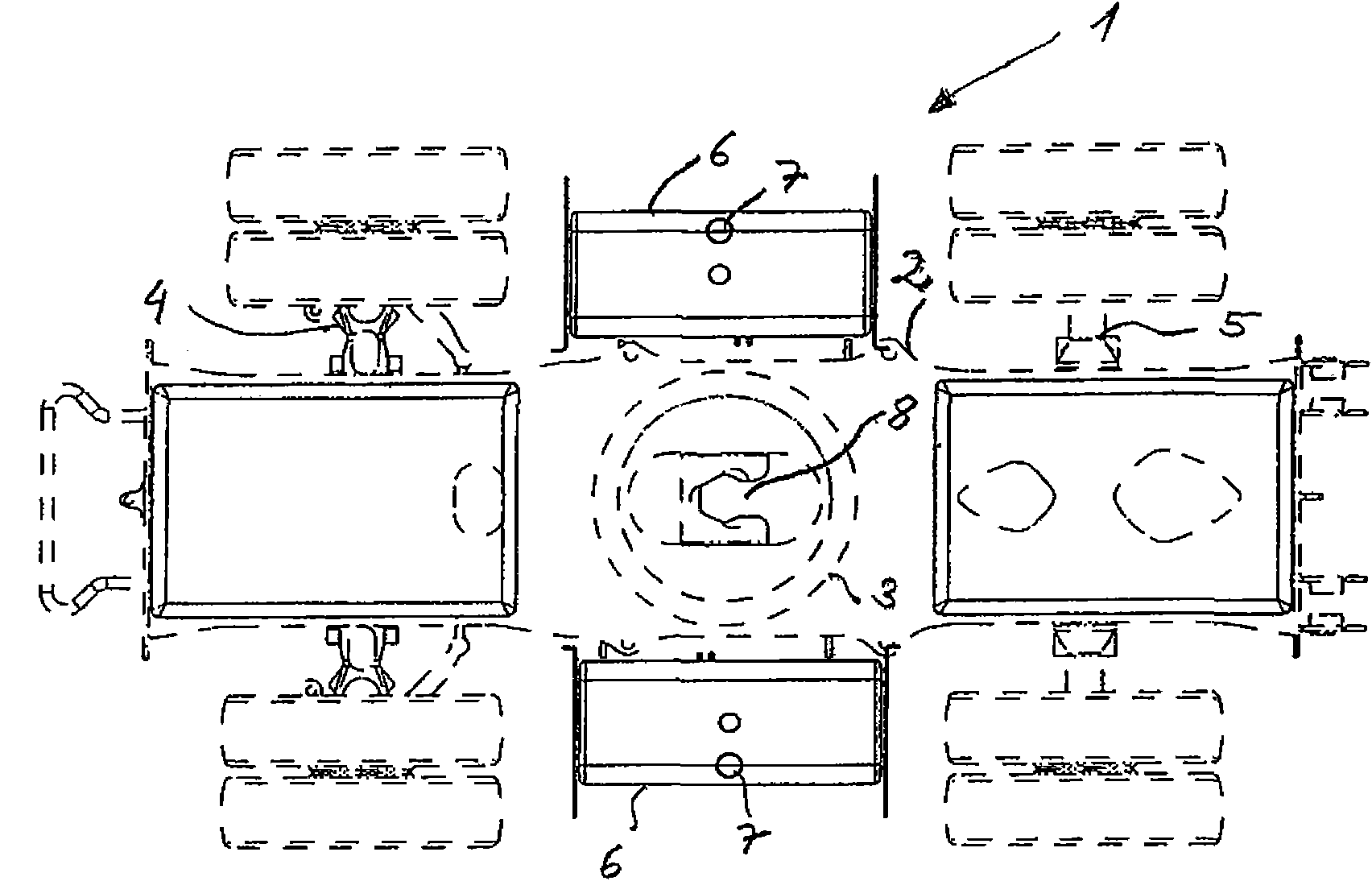

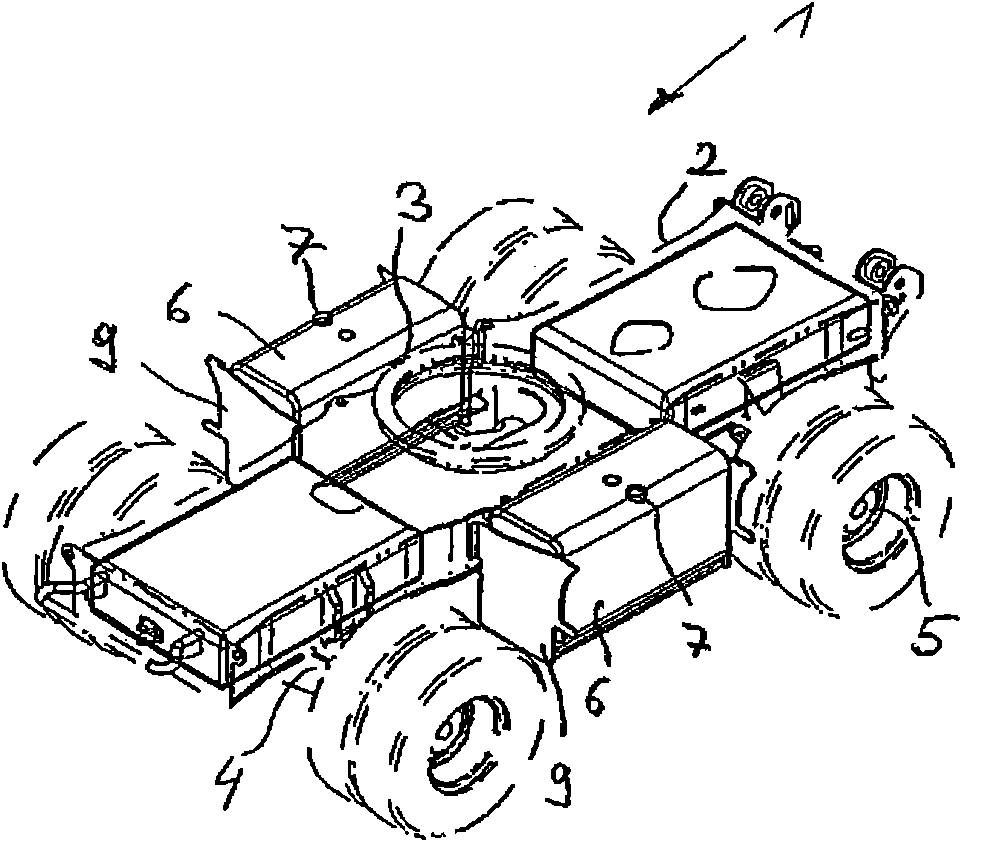

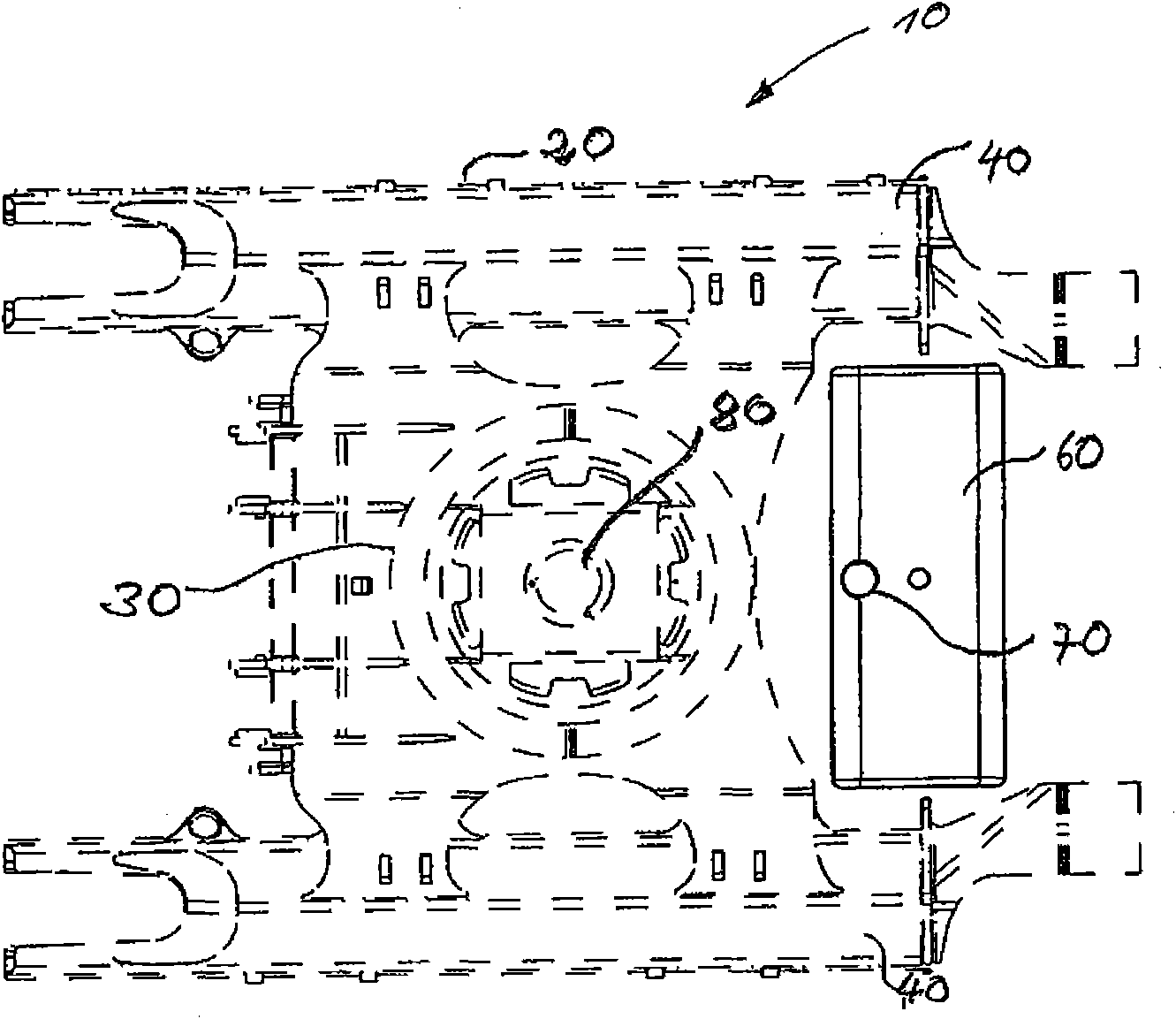

[0031] figure 1 with 2 The wheeled excavator 1 shown in has a chassis 2 and a not shown superstructure in a conventional manner. The chassis 2 has a wheeled excavator floor provided with a front axle 4 and a rear axle 5 . On the chassis 2 , the superstructure is placed on a swivel assembly 3 in such a way that it can rotate relative to the chassis 2 about a vertical axis of rotation. In addition to the operator's cab and boom, the superstructure, not shown, has a number of components including the internal combustion engine, pumps, radiators, and the like. The counterweight can be arranged in a known manner in the rear region of the superstructure.

[0032]According to the invention, the two fuel containers 6 have been relocated from the superstructure to the chassis 2, where they are fixedly arranged in figure 1 with 2 wheeled excavator 1. In this respect, a corresponding fuel container 6 is positioned to the side of the chassis 2 between the front axle 4 and the rear a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com