Fast inlaying grafting assembly swimming pool

A swimming pool, fast technology, applied in the swimming pool field, can solve the problems of long construction period, inability to disassemble, short service life, etc., and achieve the effect of smooth and flat pool wall, space saving and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

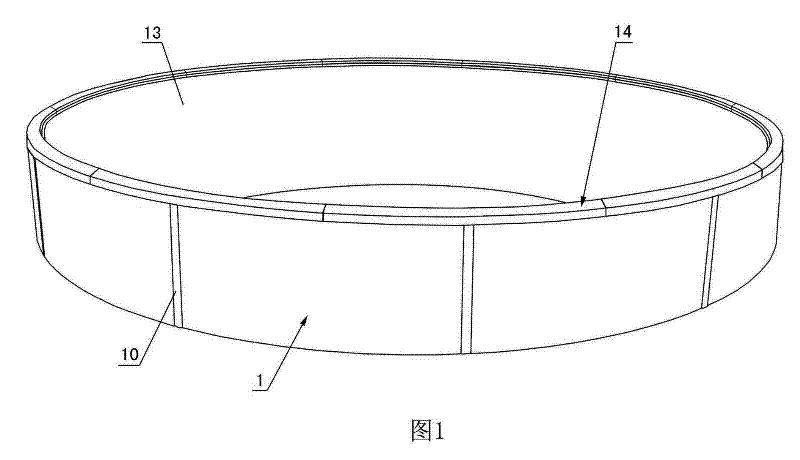

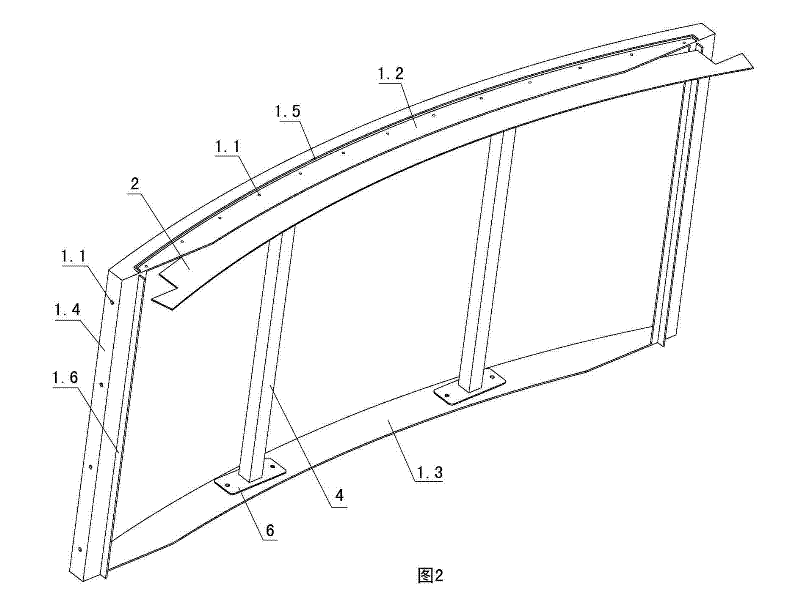

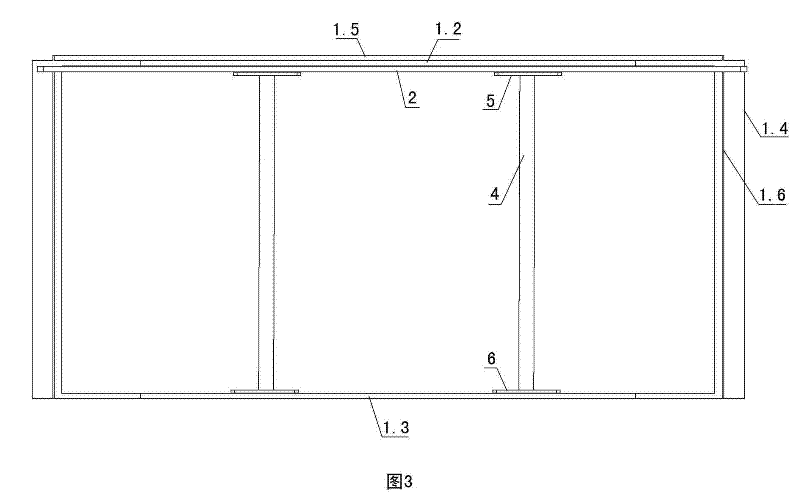

[0042] Embodiment one sees Figure 1-5As shown, this quick plug-in assembled swimming pool includes a pool bottom, a pool wall and a pool water purification device, wherein the top of the pool wall has handrails along the upper edge of the pool wall, and a layer of liner film 13 is laid on the bottom of the pool and the inside of the pool wall. The periphery of the rubber-lined film is embedded between the handrail and the pool wall on the pool wall. The pool wall is enclosed by a piece of decorative structural board 1 connected end to end, and the upper side, lower side and side of each decorative structural board 1 extend inwardly with upper flange 1.2, lower flange 1.3 and side flange respectively. Flange 1.4, wherein the inner side of the side flange 1.4 has a side flange support plate 9, and the outer side of the side flange 1.4 is wrapped with a U-shaped profile 8. The decorative structural board 1 can be a glass steel plate, a metal plate, an aluminum-plastic plate, a ...

Embodiment 2

[0051] Embodiment two see Figure 13 , Figure 14 , different from Embodiment 1, the outer bottom of the pool wall is connected with a circulating water tank 21 through silica gel or rubber, and the inner rubber film 13 is also laid in the circulating water tank, and one side of the inner rubber film 13 is connected with the silicone or rubber The rubber connection, the other side is connected in the draw-in groove 22 at the outer end of the circulating water tank 21 . One end of the water suction pipe 24 is located in the circulating water tank 21 and the other end is located in the swimming pool. When in use, the water in the swimming pool continuously overflows into the circulating water tank, and is continuously sucked back into the swimming pool through the water suction pipe 24 to form a circulating water tank. system.

[0052] The multi-functional threaded hole 7.3 has multiple purposes, such as being able to externally connect various peripherals such as parasols, mu...

Embodiment 3

[0053] Embodiment three see Figure 15 , different from Embodiment 1, the inner liner film 13 extends upwards with an upper edge waterproof cover 25, and the upper edge waterproof cover 25 wraps the upper edge handrail of the pool wall and extends into the upper edge handrail board of the pool wall In the water retaining plate 14.2 of 14, the rear blocking block 23 is fixed between the water retaining plate and the decorative structural plate.

[0054] The present invention can be placed on the ground, or a pit can be dug on the ground, and the present invention can be placed in the pit, and the present invention can also be placed in water. The present invention can be various shapes such as circle, ellipse, oblong circle, square or polygon, and this embodiment is circle, and the described decorative structural plate is designed as an arc plate, and the cross-section of the injection molded connector is designed as a trapezoid or triangle; in other embodiments, in order to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com