Active clearance compensation type cycloid pump/ motor device

A clearance compensation, cycloid technology, used in combustion engines, machines/engines, rotary piston pumps, etc., can solve problems such as uneven wear of cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

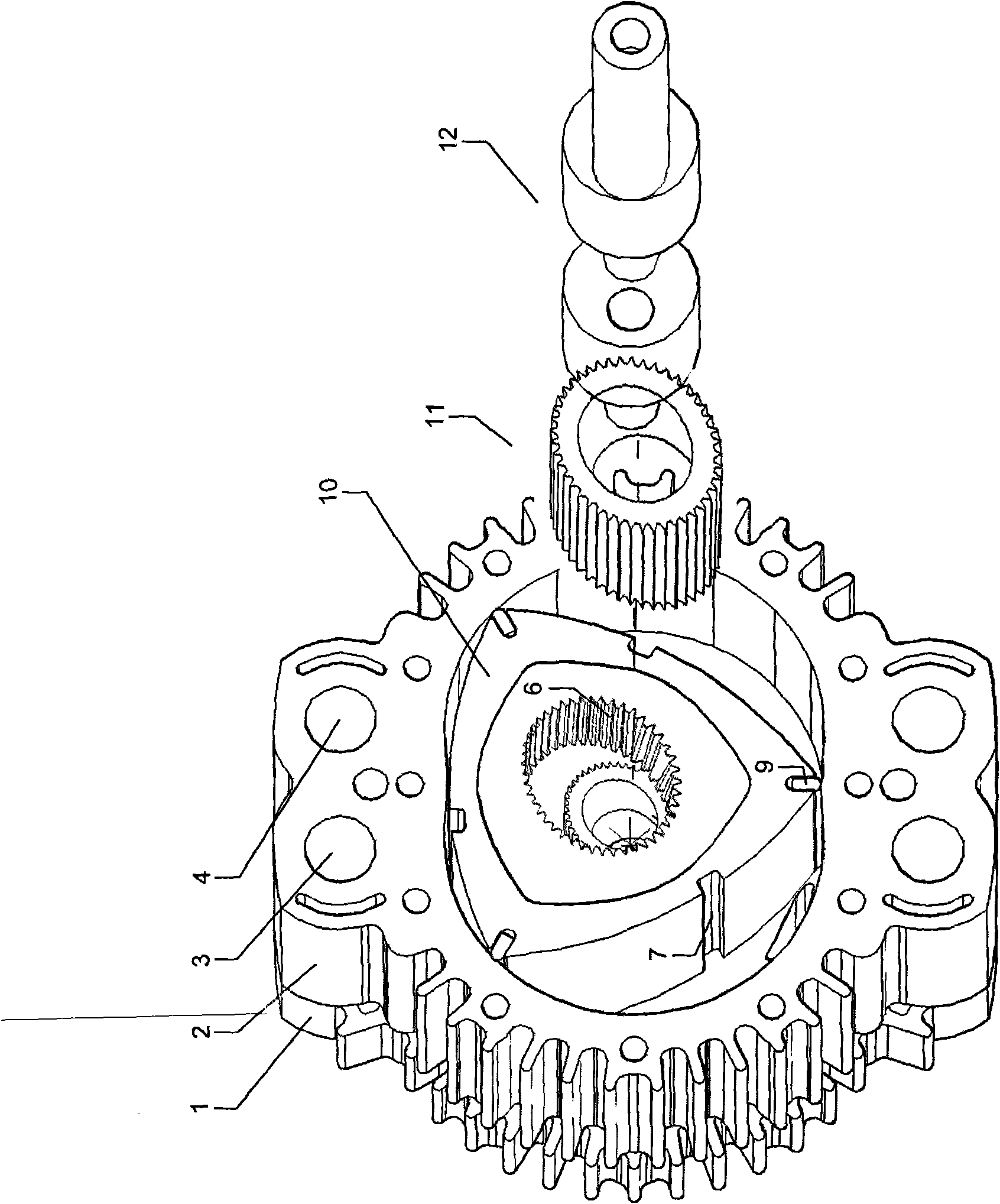

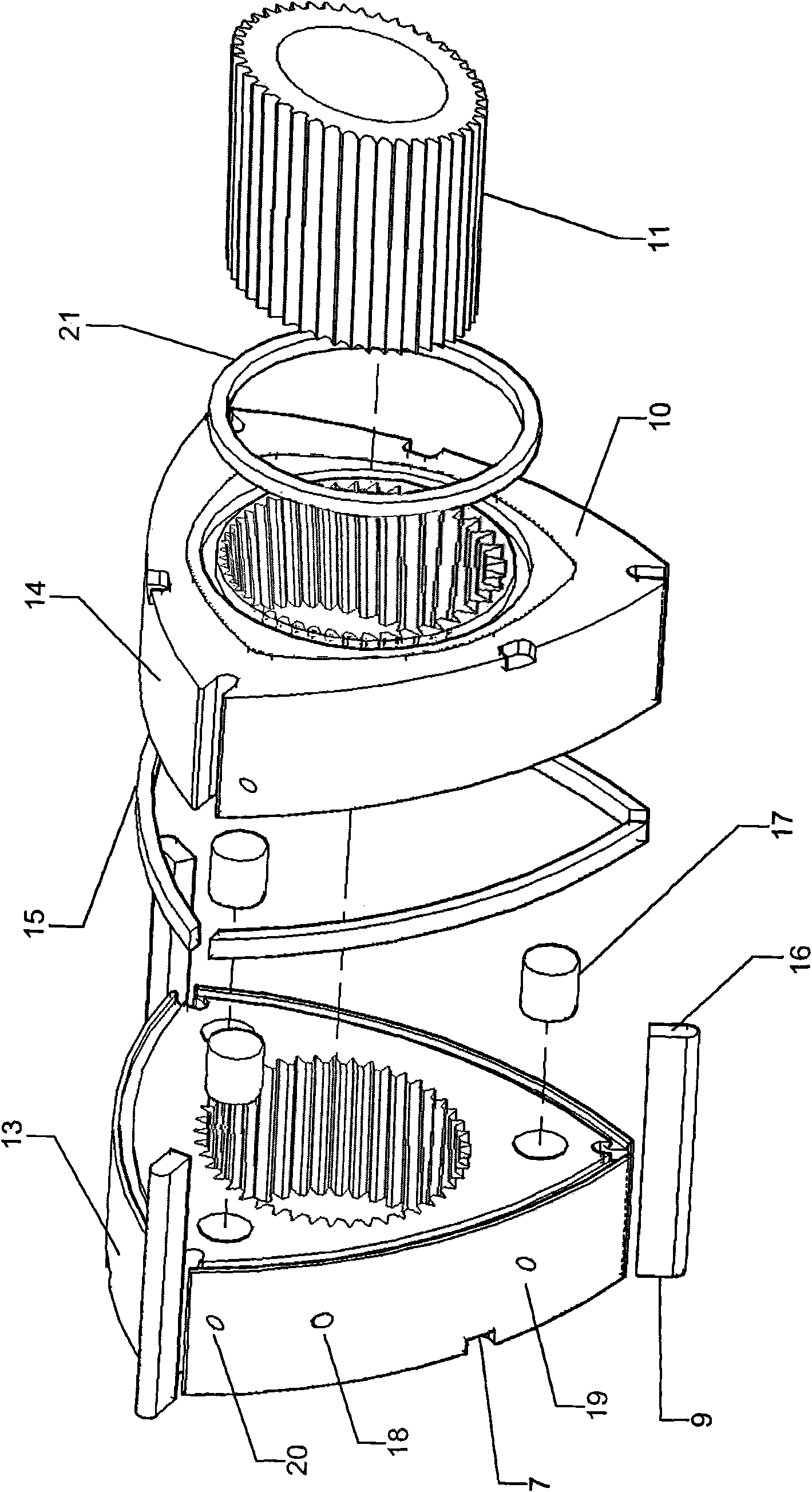

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

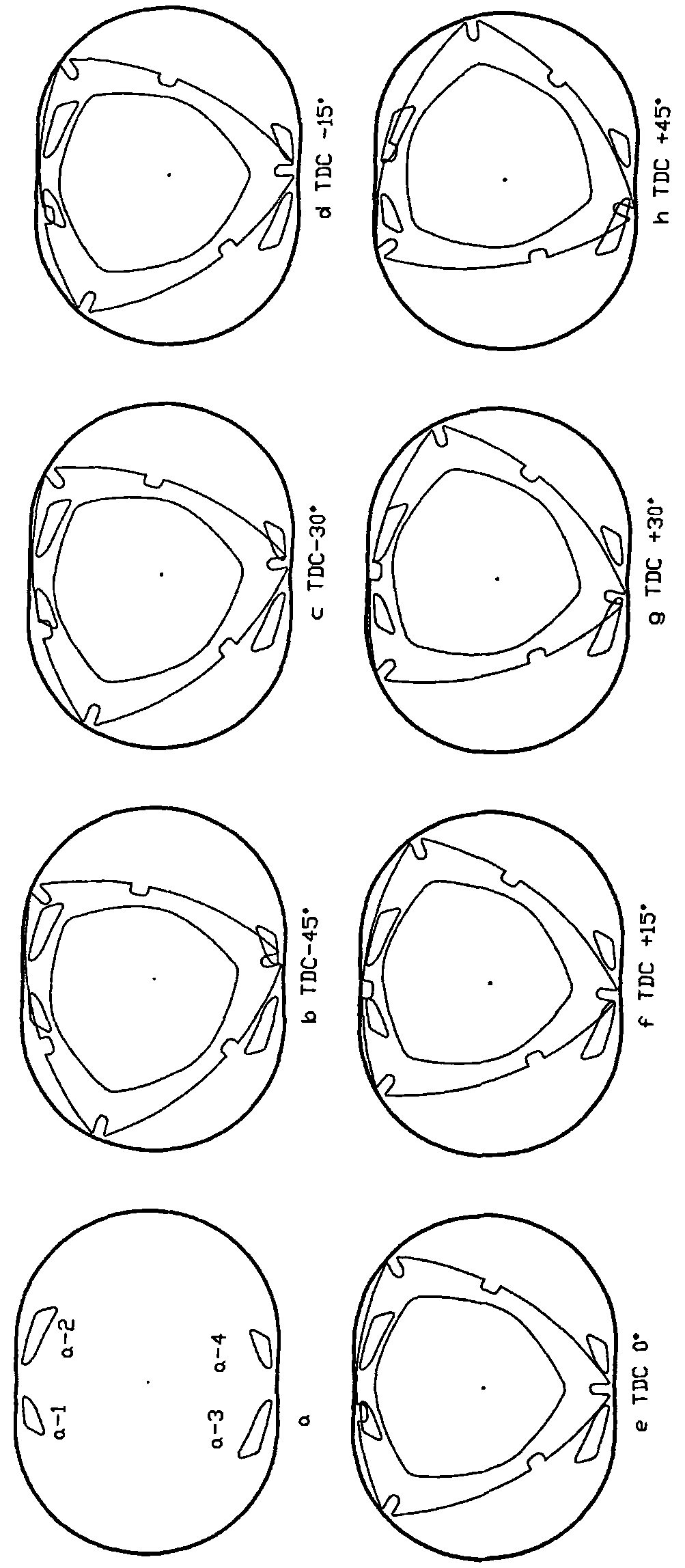

[0023] A symmetrical four-open cycloidal pump / motor with interchangeable mechanical energy and pressure. It is a circular running device that can pressurize gas or fluid or be pushed by pressurized gas and fluid. The principle is to use the epicycloid of a circle The regularity of running along the trajectory, the apex of the triangular central rotor moves along this trajectory to cause the space to expand and contract, and then pressurize or be reacted by the gas or fluid.

[0024] Please refer to Figure 1 to Figure 3 As shown, the active gap compensation type cycloidal pump / motor device of the present invention has a structure: a side plate of a cycloidal cylinder, on which two symmetrical air inlets 4 and two outlets 3 are arranged. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com