Thread cartridge balanced valve

A threaded cartridge and balance valve technology, applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as system instability, low-frequency jitter, and different connection sizes, so as to facilitate serialization and reduce weight , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

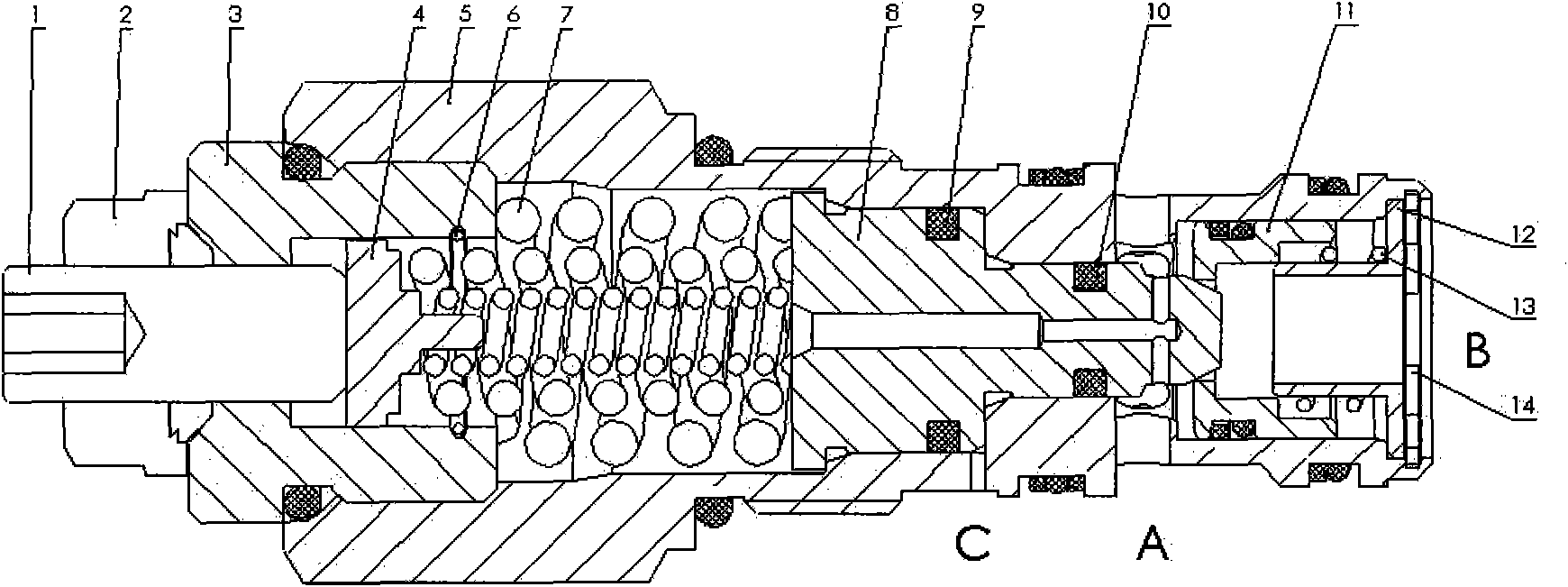

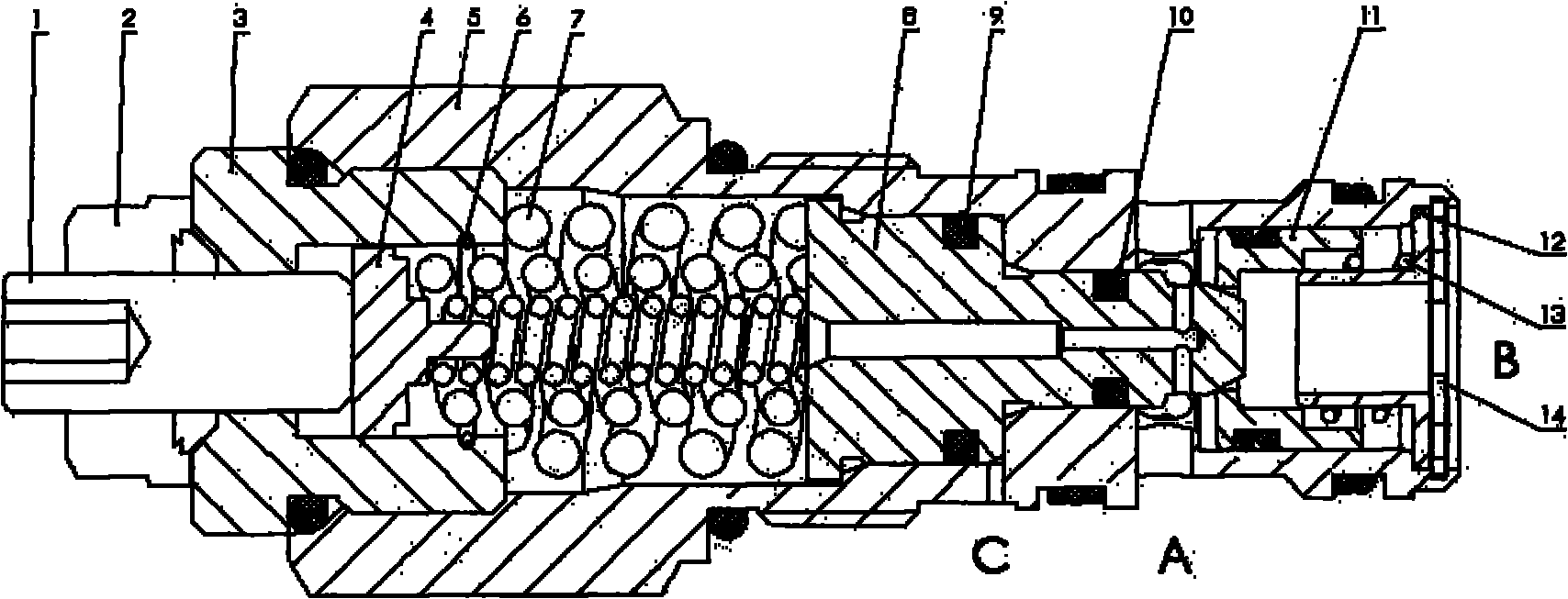

[0016] The basic structure of the threaded cartridge balance valve of this embodiment is as follows: figure 1 As shown, the threaded cartridge balance valve is mainly composed of a sealing nut 2, a valve body 5, a spring set 7, a valve core 8, and a valve seat 11. The valve seat 11 is connected with the valve core 8 front and back, and forms a one-way control valve structure with the conical structure end of the valve core 8, while the pilot valve core is located at the other end of the valve core 8, which is stepped and connected to the valve body 5, The airtight cavity formed by the sealing rings 9 and 10 is connected with the control oil port C to form a pilot control oil circuit. The valve body 5 is in a cylindrical shape, and the sealing rings 9 and 10 are grey ring sealing structures.

[0017] The valve body 5 is connected with the valve core 8 through the spring group 7, the piston 4, and the valve cover 3 to form a multiple load-sensitive whole. The spring group 7 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com