Constant speed control method of hydraulic cylinder type actuator and device thereof

An actuator and constant velocity control technology, applied in fluid pressure actuators, mechanical equipment, servo motor components, etc., can solve the problems of inconsistent speed of piston rod extension and retraction, high cost of implementation, complex structure, etc. Accurate and easier to achieve motion trajectory control, improve construction quality, and good motion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

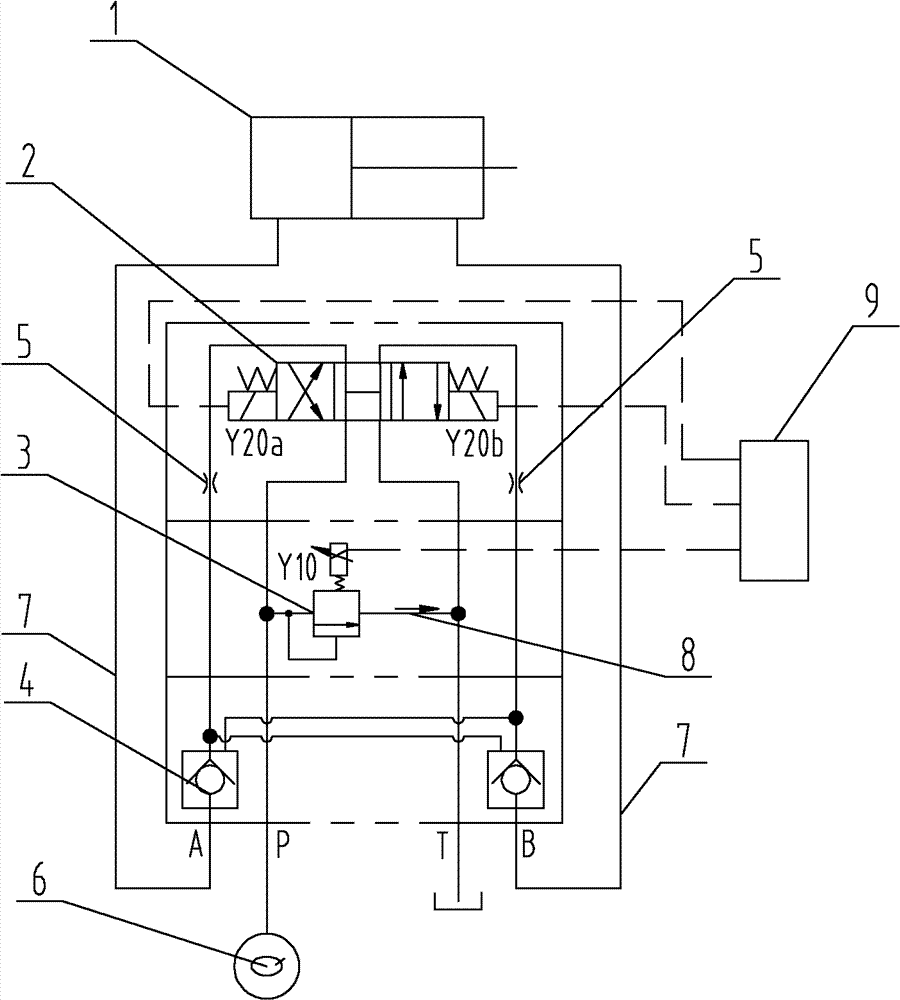

[0014] like figure 1 As shown, the constant velocity control method of the hydraulic cylinder type actuator of the present invention, the piston rod of the hydraulic cylinder is used as the actuator, the rodless chamber and the rod chamber of the hydraulic cylinder are respectively connected with the electromagnetic reversing valve through the oil circuit, each oil circuit All are equipped with a throttling plug, the electromagnetic reversing valve is connected with the oil supply unit, and the oil circuit between the electromagnetic reversing valve and the oil supply unit is equipped with an electric proportional overflow valve and an overflow circuit; the electric control system is based on the construction environment. Change control The electromagnetic reversing valve controls the direction of the piston rod and at the same time a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com