Multi-fragment stopping combustor for combustible cartridge case

A technology of burners and fragments, which is applied in the direction of instruments, ammunition, fuel oil testing, etc., can solve the problems of fast movement, damage, and high pressure of medicine particles, and achieve the goal of improving fine diagnosis, improving accuracy, and filling the gaps in existing technologies Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments given by the inventor.

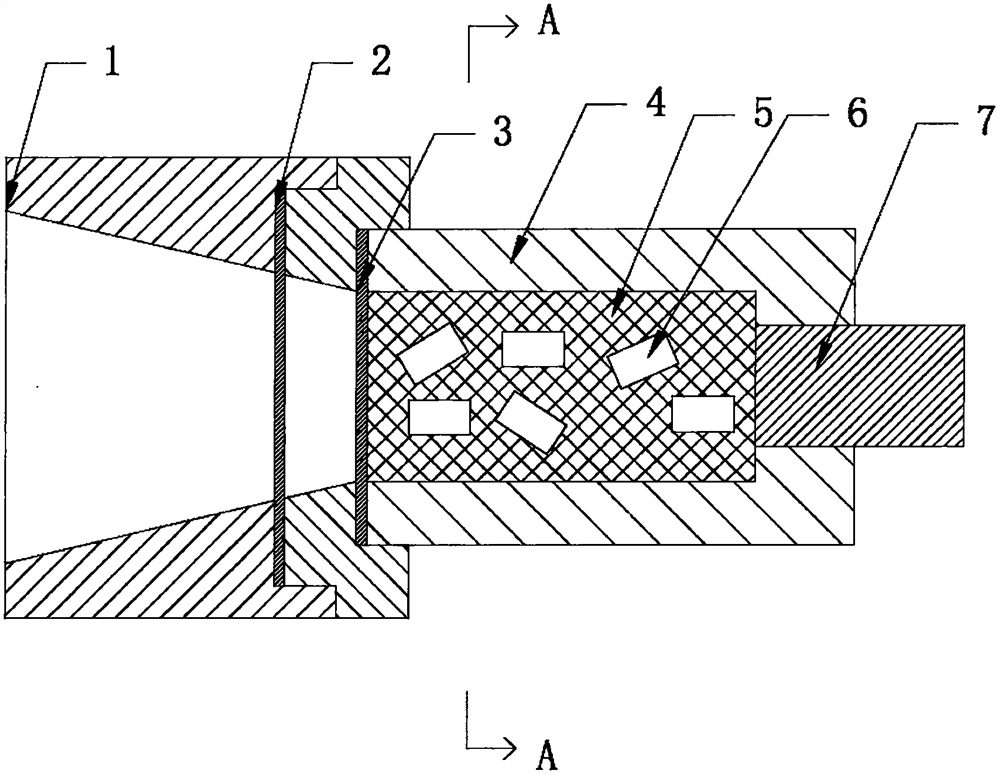

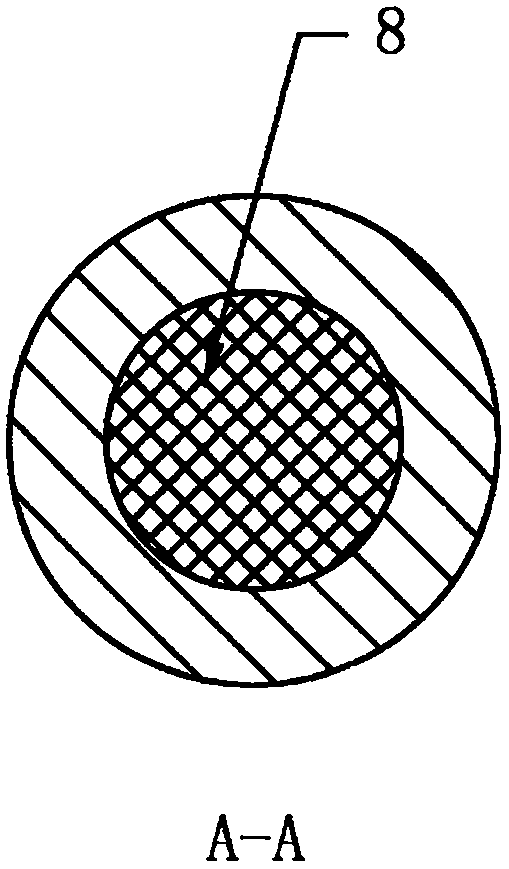

[0023] like figure 1 , figure 2 As shown, this embodiment provides a preferred structure of a multi-fragment stop burner for a combustible cartridge, including a multi-stage nozzle 1, a velocity-controlling fragment 2, a pressure-controlling fragment 3, a body 4, an ablation cage 5, and a combustible cartridge. Sheet 6, screw plug 7;

[0024] The multi-stage nozzle 1 is a trumpet-shaped structure, with a trumpet-shaped interior and a cylindrical exterior. The material is 45# steel, the size is Φ120mm×160mm, and it consists of two segments. The inner diameter of the left end of the first segment is Φ80mm, the length is 100mm, the inner diameter of the right end is Φ60mm, the inner diameter of the left end of the second segment is Φ58mm, the length is 60mm, the inner diameter of the right end is Φ50mm, there is a gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com