Liquid excess pressure energy recovery device

A technology of energy recovery and residual pressure, which is applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of bulky, decreased safety and stability, and heavy maintenance workload, etc., and achieve volumetric efficiency High, convenient design, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

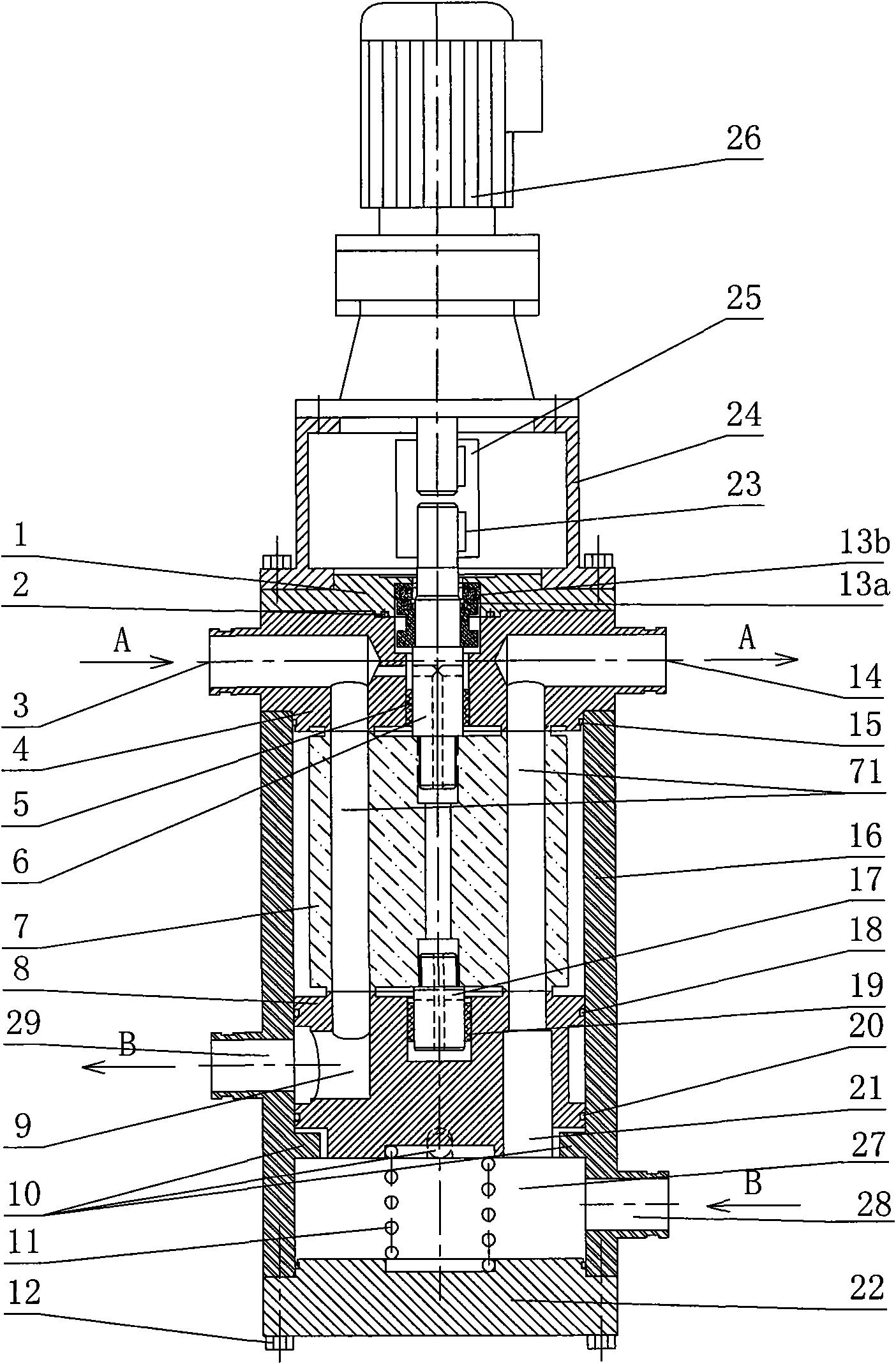

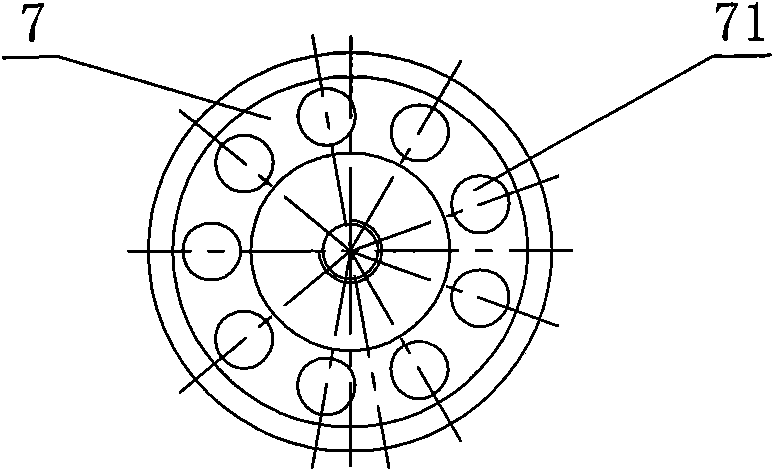

[0023] Refer to attached picture. The present invention includes a drive motor 26 and a rotating assembly, the rotating assembly includes: a moving ring 13a for mechanical sealing, a drive shaft 6, a rotor 7, and a driven shaft 17, and the rotor 7 is evenly provided with 9 drive shafts along the circumference. axially parallel flow channels 71 of the shaft;

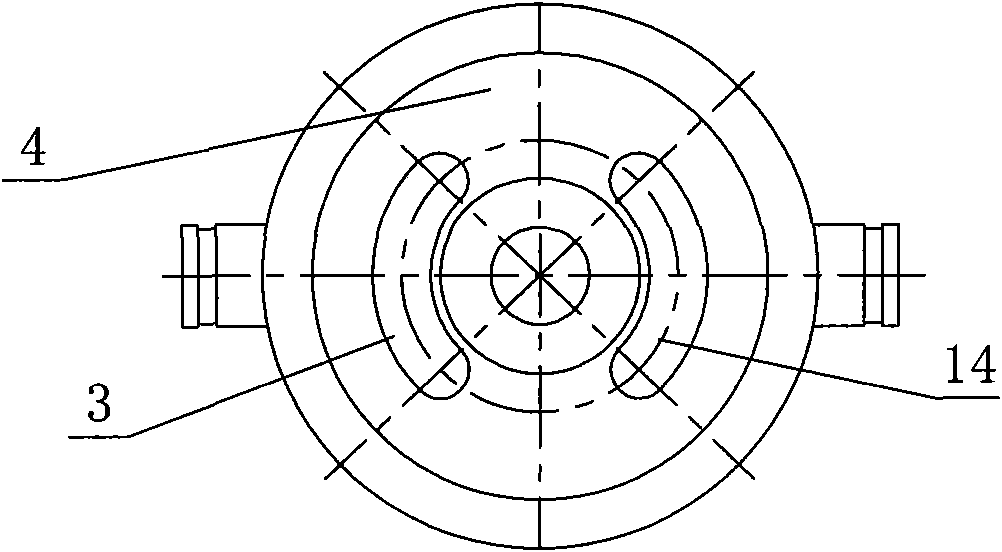

[0024] The pressure exchanger is also provided with a non-rotating assembly, which includes a mechanical seal cover 1, a static ring 13b for mechanical sealing, a fixed flow distribution plate 4, a floating flow distribution plate 8, a housing 16, a compression spring 11, Outer end cover 22 and bolts 12; the fixed flow distribution plate 4 is provided with a relatively low pressure fluid inlet 3, a relatively high pressure fluid outlet 14 and the shaft sleeve 5 of the drive shaft is installed, and the floating flow distribution plate 8 is provided with a relatively low pressure fluid Outlet 9, relatively high-pressure fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com