Chemical-looping combustion system of parallel fluidized bed

A technology of chemical chain combustion and fluidized bed, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in molten state, combustion method, etc., can solve the problem of limited transfer amount of oxygen carrier, easy to scale up operation and transfer resistance when reaching a large scale The effect of reducing and reducing the transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the drawings:

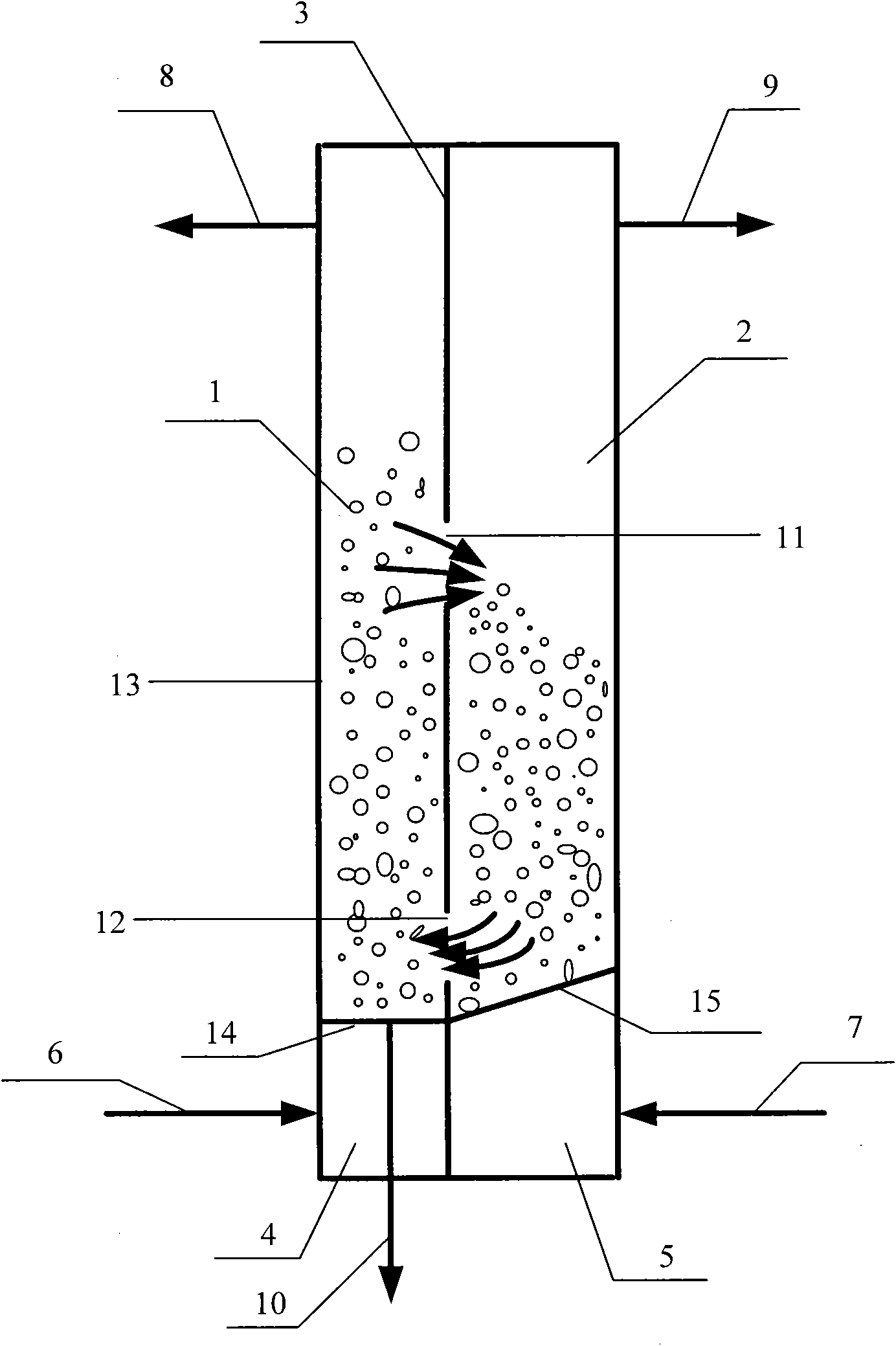

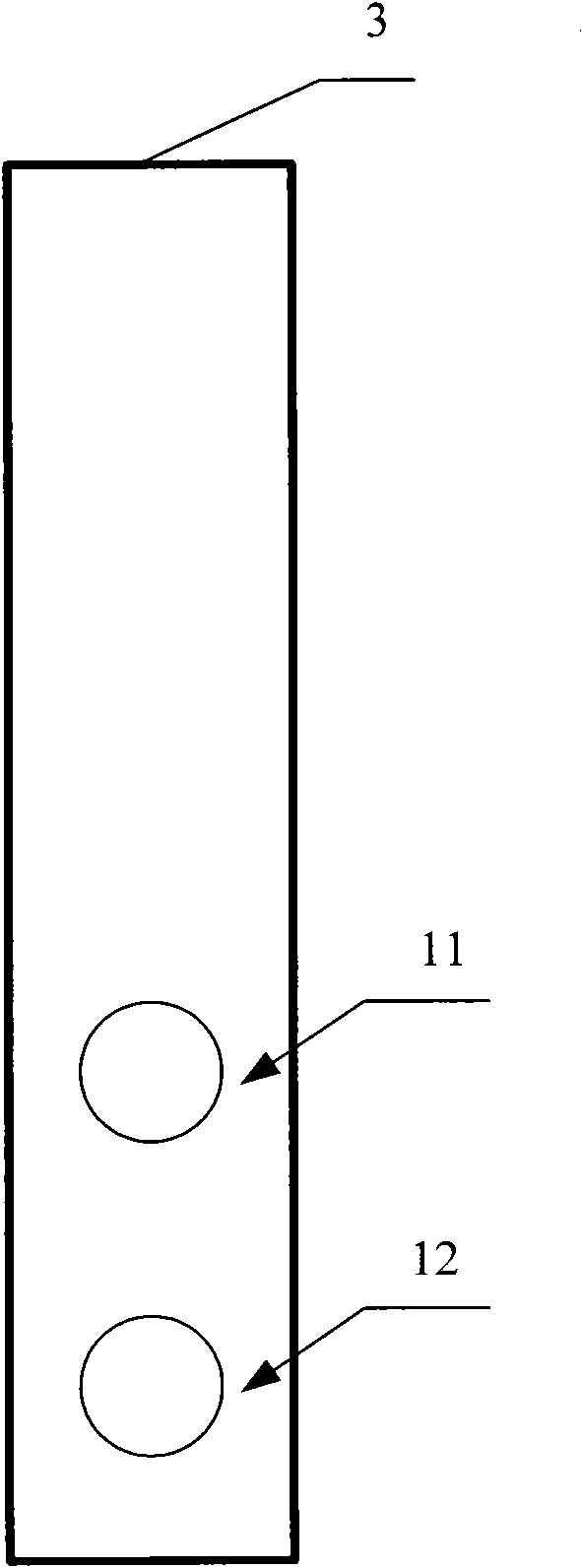

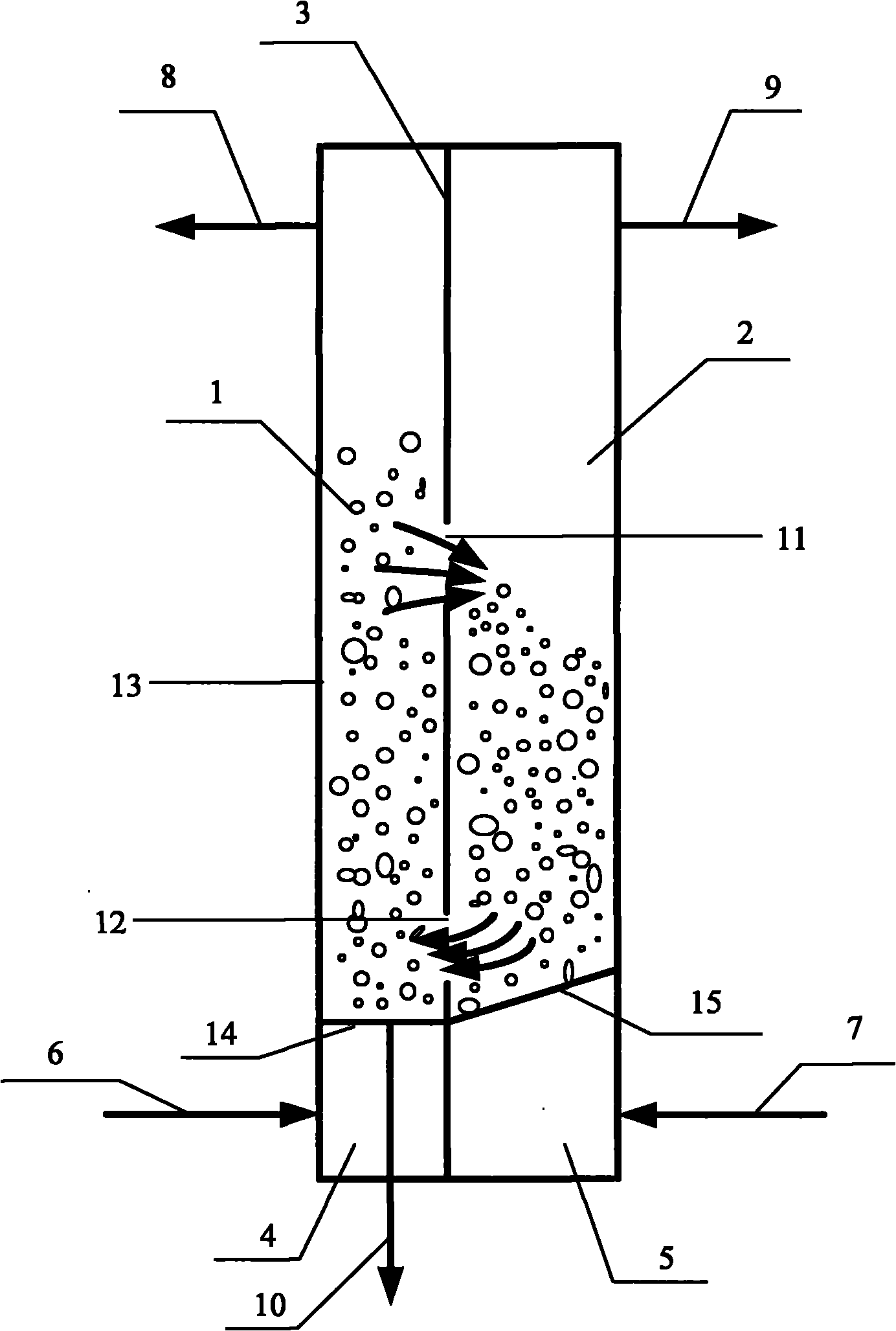

[0022] A parallel fluidized bed chemical chain combustion system, such as figure 1 As shown, the system includes a parallel fluidized bed cylinder 13, which is divided into two cavities by a partition 3, one cavity is the fuel reactor 1, and the other cavity is the air reactor. 2. The partition 3 is provided with a hole 12 and b hole 11, and the material passes through the a hole 12 and b hole 11 on the partition 3 for material and energy exchange; parallel fluidized bed chemical chain combustion system The schematic diagram of the partition is as figure 2 Shown

[0023] The upper part of the fuel reactor 1 is provided with a gas-solid outlet 8 for connecting to its gas-solid separator, the lower part is provided with an air distribution plate 14 and a wind chamber 4, and the wind chamber 4 of the fuel reactor 1 is provided with a gas inlet 6;

[0024] The upper part of the air reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com