Capillary leak-proof distributor

A capillary and anti-leakage technology, applied in the direction of fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve the problems of unqualified welding, refrigerant leakage, thick thickness, etc., and achieve the effect of improving service life, simple structure, and avoiding refrigerant leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

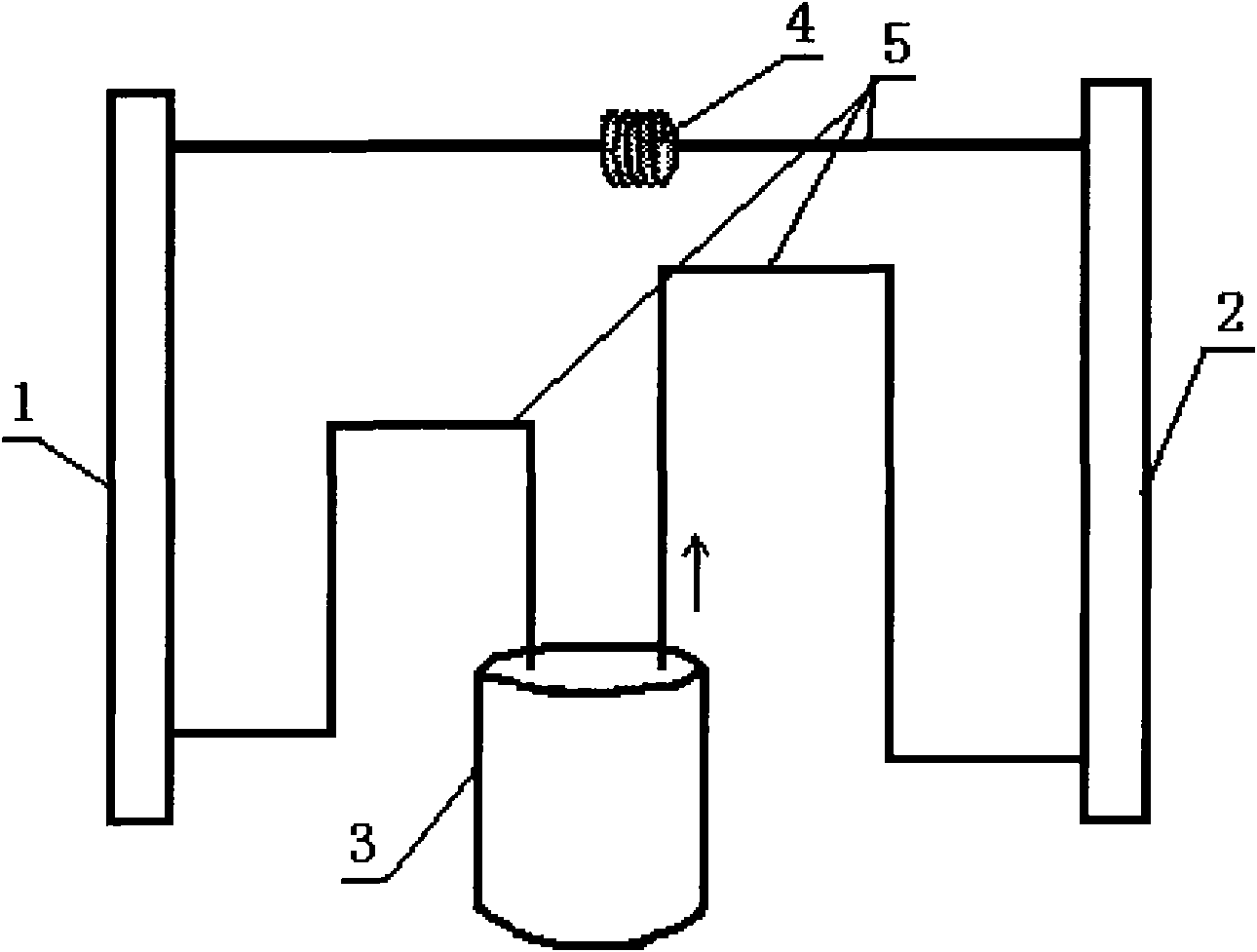

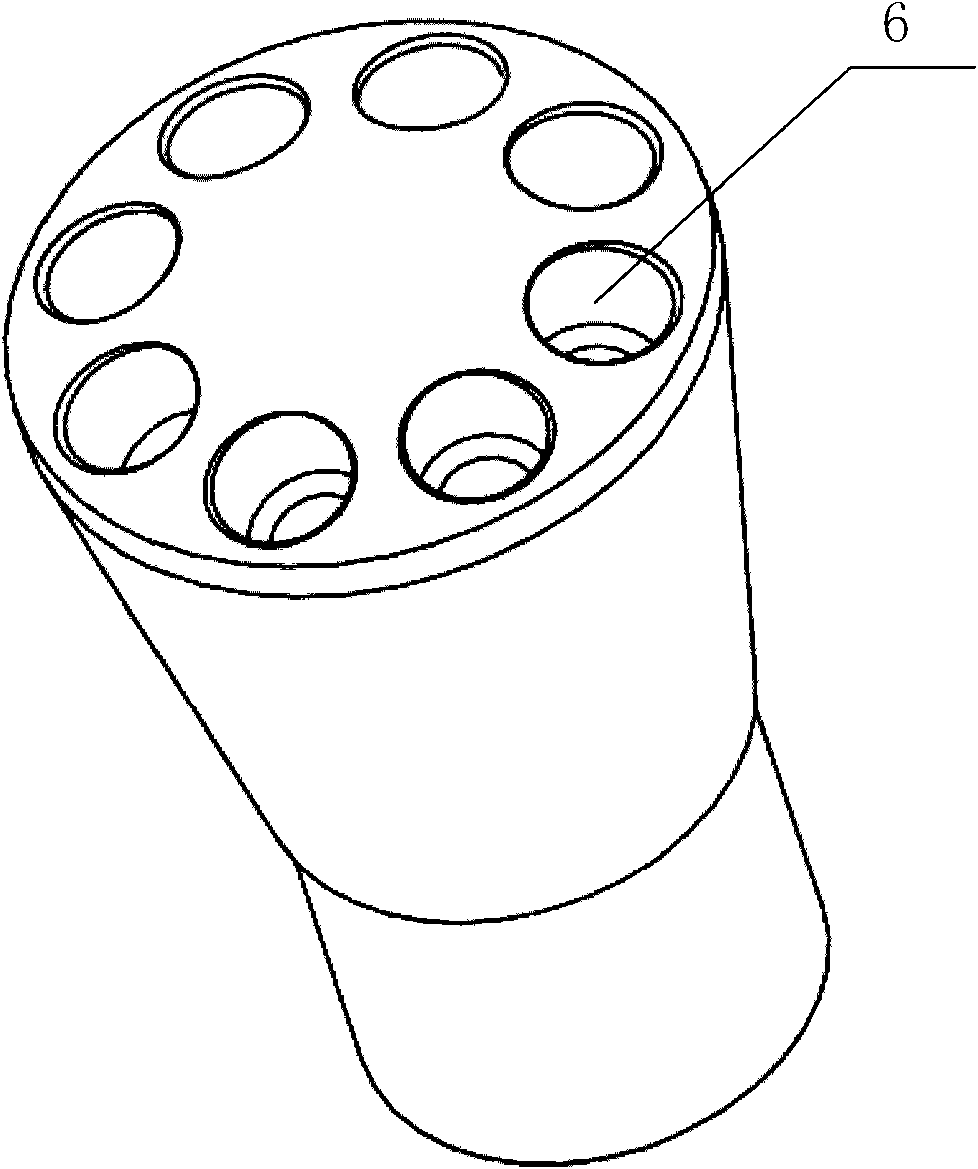

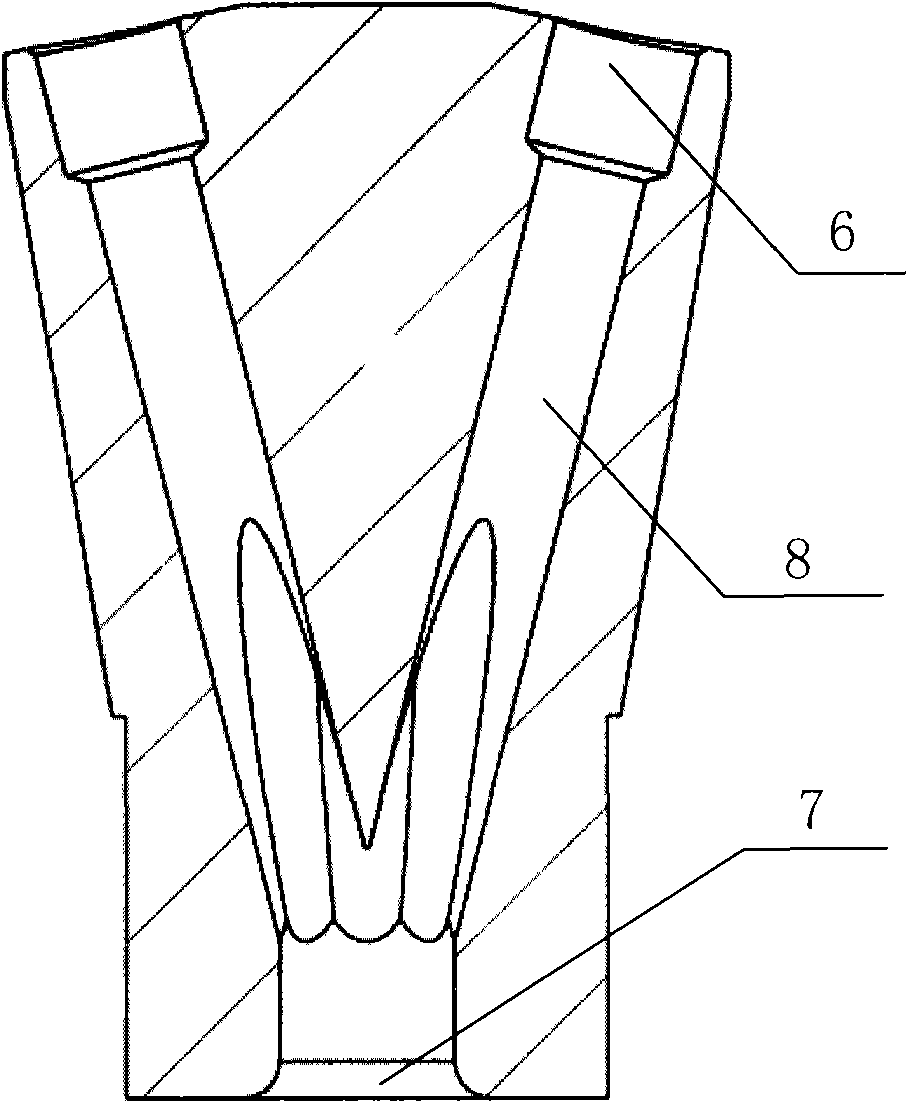

[0027] Hereinafter, the anti-leakage dispenser for capillary tubes of the present invention will be described in detail with reference to the drawings and examples.

[0028] Such as Figure 4 , Figure 5 As shown, the anti-leakage distributor for capillary of the present invention includes a main body 9, a plurality of capillary connection sockets 6 for connecting capillaries are formed at one end of the main body 9, and a plurality of capillary connection sockets 6 for connecting refrigerant pipes are formed at the other end of the main body 9. The refrigerant pipe connection socket 7, the plurality of capillary connection sockets 6 correspondingly form a plurality of channels 8 inside the main body 9, and the other ends of the plurality of channels 8 are collected at the refrigerant pipe connection socket 7, so that multiple A capillary connection socket 6 and a refrigerant pipe connection socket 7 communicate with each other. Therefore, each capillary connected to each ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com