Multi-temperature zone refrigerating system PD energy-saving control method

A refrigeration system and energy-saving control technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems that it is difficult to achieve good results, long time for compensating temperature, high frequency of starting and stopping, and achieves low cost and extended Long service life and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

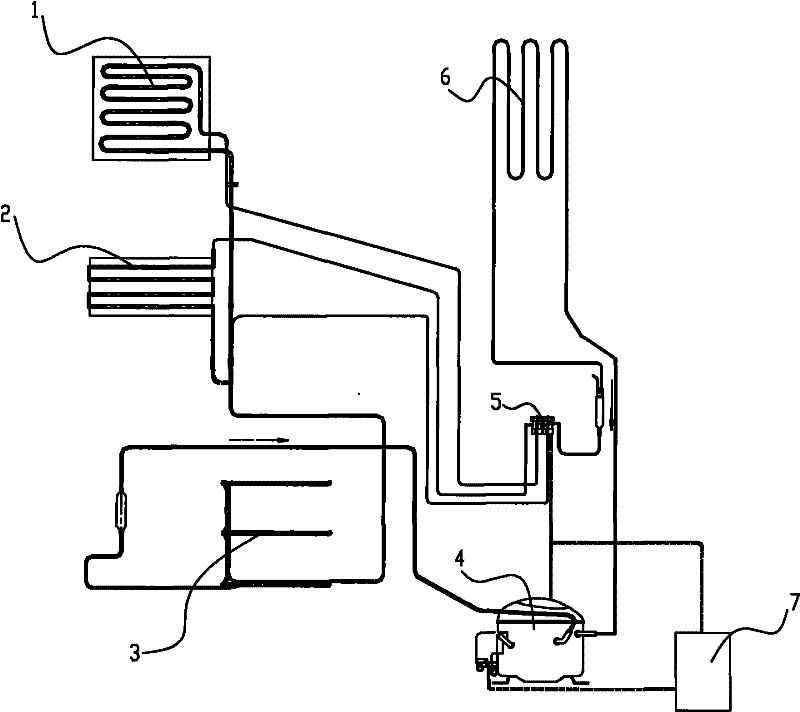

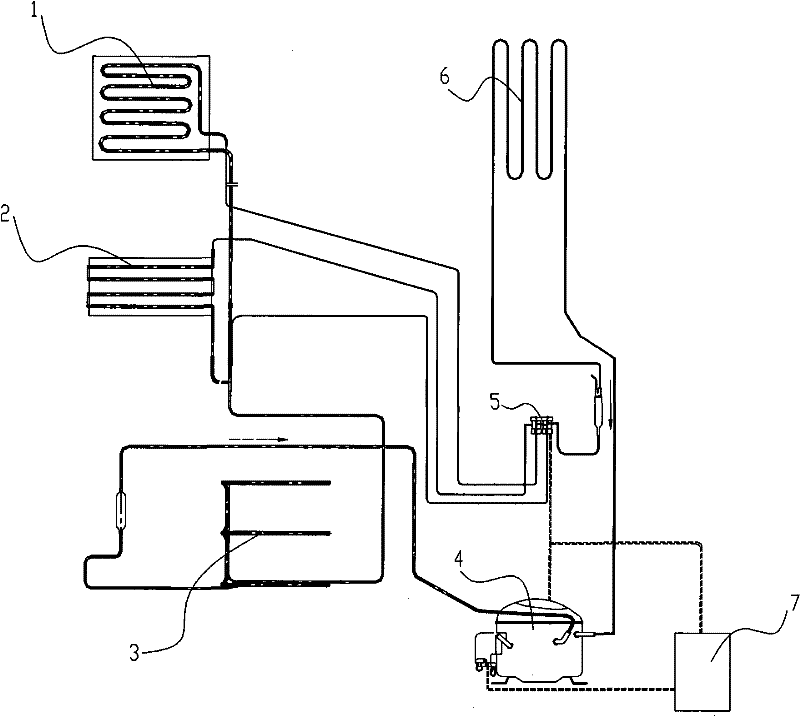

[0015] A PD energy-saving control method for a multi-temperature zone refrigeration system. A multi-temperature zone refrigeration system is selected. The multi-temperature zone refrigeration system includes a compressor, a condenser, an evaporator corresponding to two or more different temperature zones, a step valve, and a refrigeration system In the operation control part, the step valve is used to switch between the evaporators in different temperature zones to adjust the flow direction of the refrigerant; in the above operation control part, a PD single-chip microcomputer is set, and the PD single-chip microcomputer is used to pass through the temperature of each temperature zone before each compressor stops. According to the temperature rise characteristic, the downtime maintained in each temperature zone is approximately calculated. If the downtime in the variable temperature zone is shorter than the reference downtime, then the temperature pull time to be compensated is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com