Cooling tower integrated energy-saving system based on power synthesizer and control method thereof

An energy-saving system and control method technology, which is applied to water shower coolers, heat exchanger types, direct contact heat exchangers, etc. Icing phenomenon, the effect of reducing extra wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

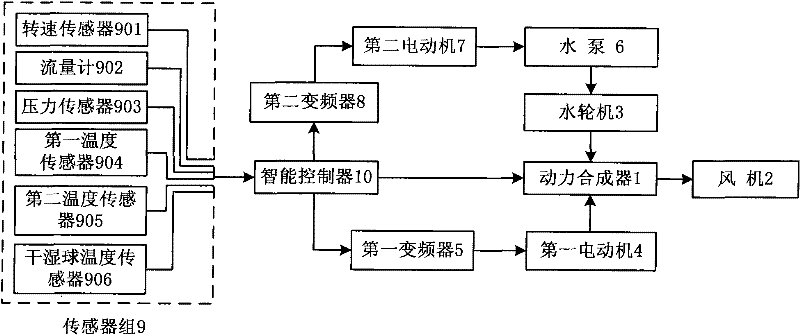

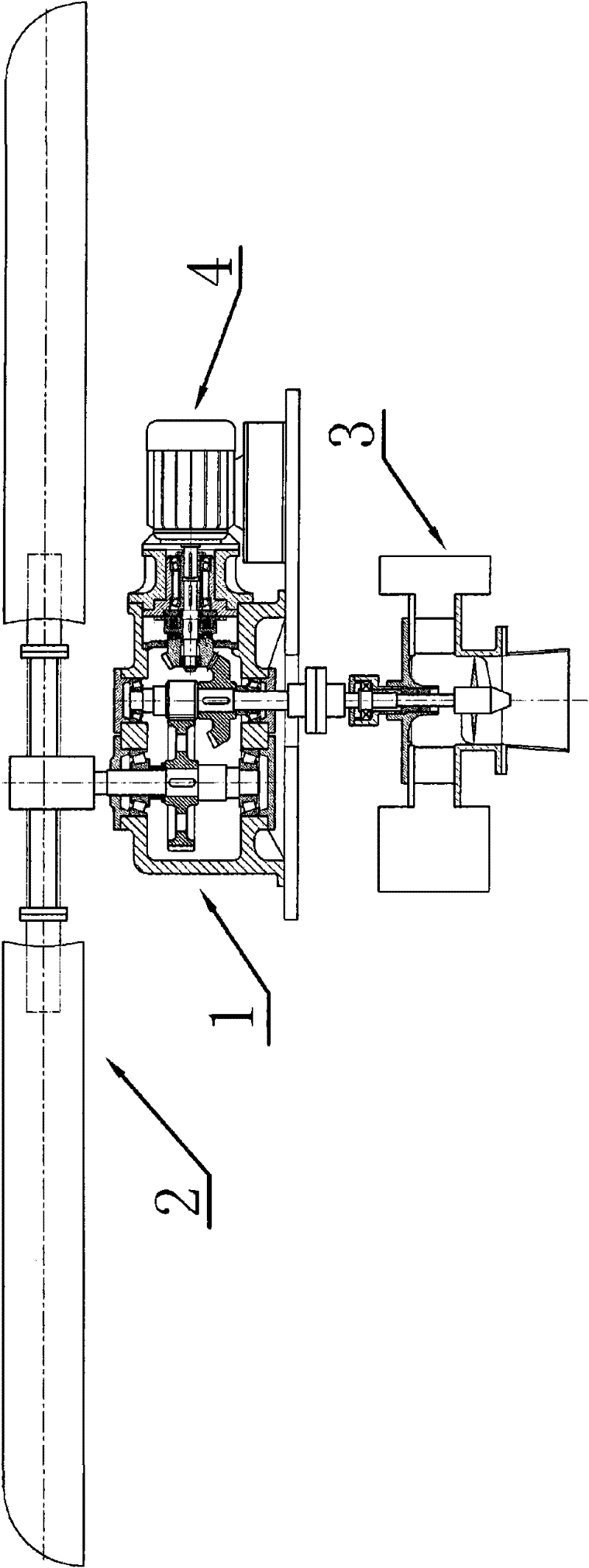

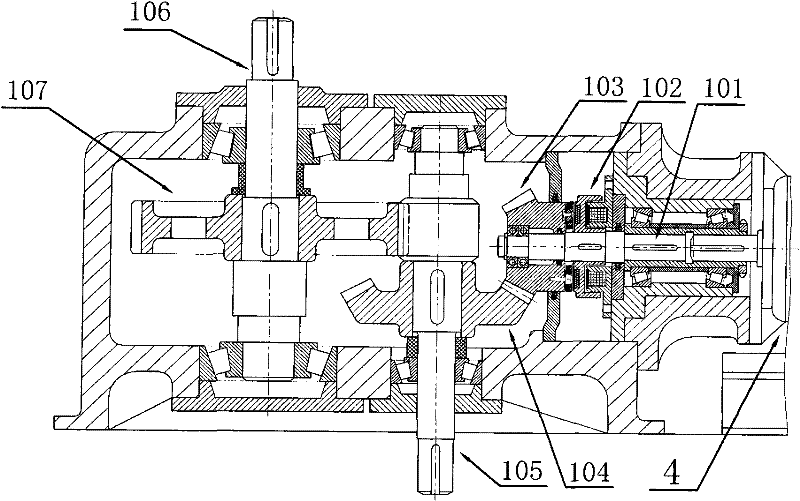

[0032] like figure 1 As shown, the comprehensive energy-saving system of cooling tower based on power combiner mainly includes: power combiner 1, fan 2, water turbine 3, first motor 4, first frequency converter 5, water pump 6, second motor 7, second frequency converter 8. Sensor group 9, intelligent controller 10, etc. The sensor group 9 includes a rotational speed sensor 901 , a flow meter 902 , a pressure sensor 903 , a first temperature sensor 904 , a second temperature sensor 905 , and a wet and dry bulb temperature sensor 906 . The rotational speed sensor 901 is located at the output shaft end of the power combiner, the flow meter 902, the pressure sensor 903 and the first temperature sensor 904 are located at the inlet of the circulating cooling water pipeline of the cooling tower, and the second temperature sensor 905 is located at the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com