Combination of cantilever part and magnetic head folding sheet with vibrating sensor and manufacturing method thereof

A vibration sensor and cantilever technology, applied in the field of information recording disk drive units, can solve problems such as damage to the vibration sensor, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

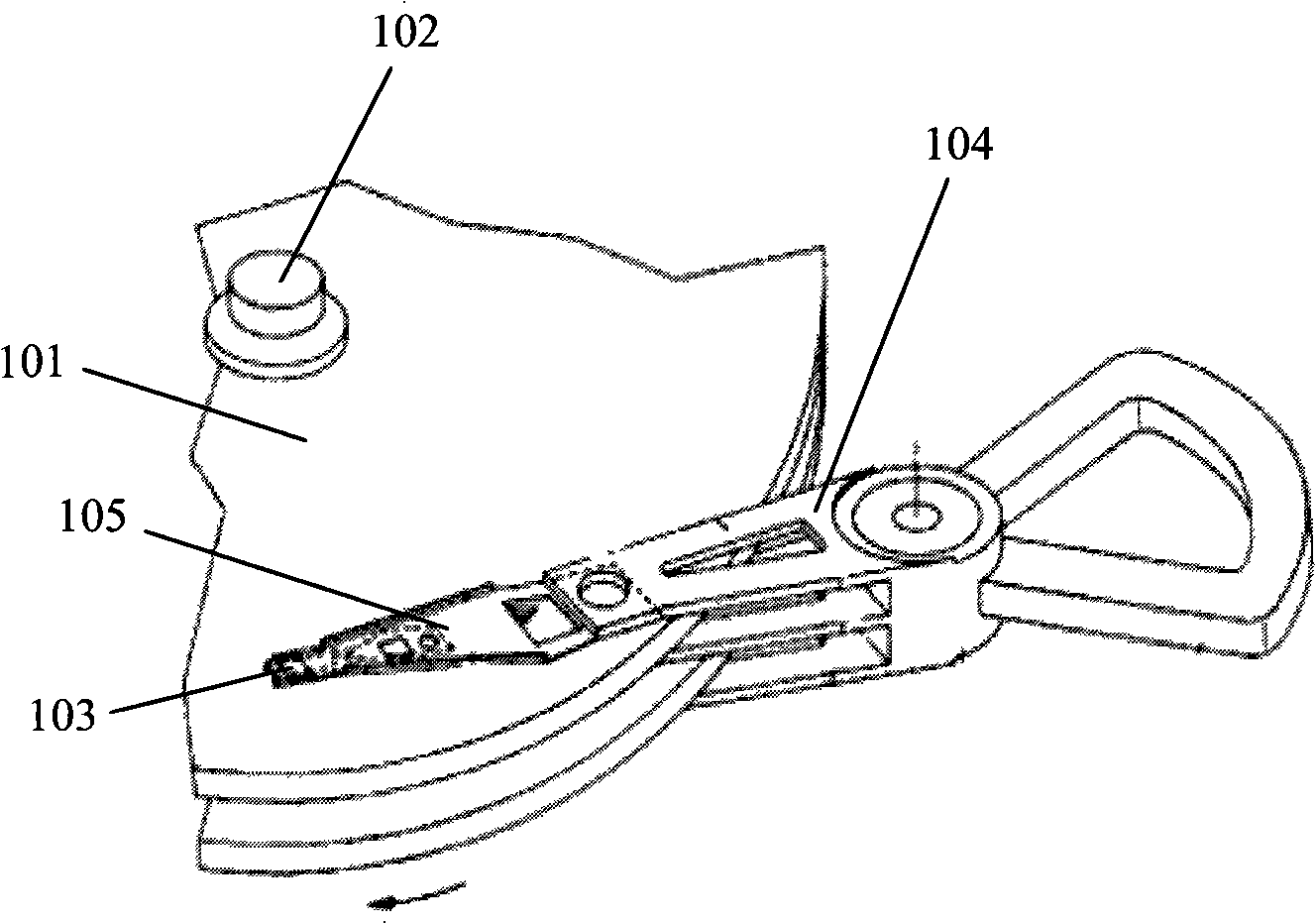

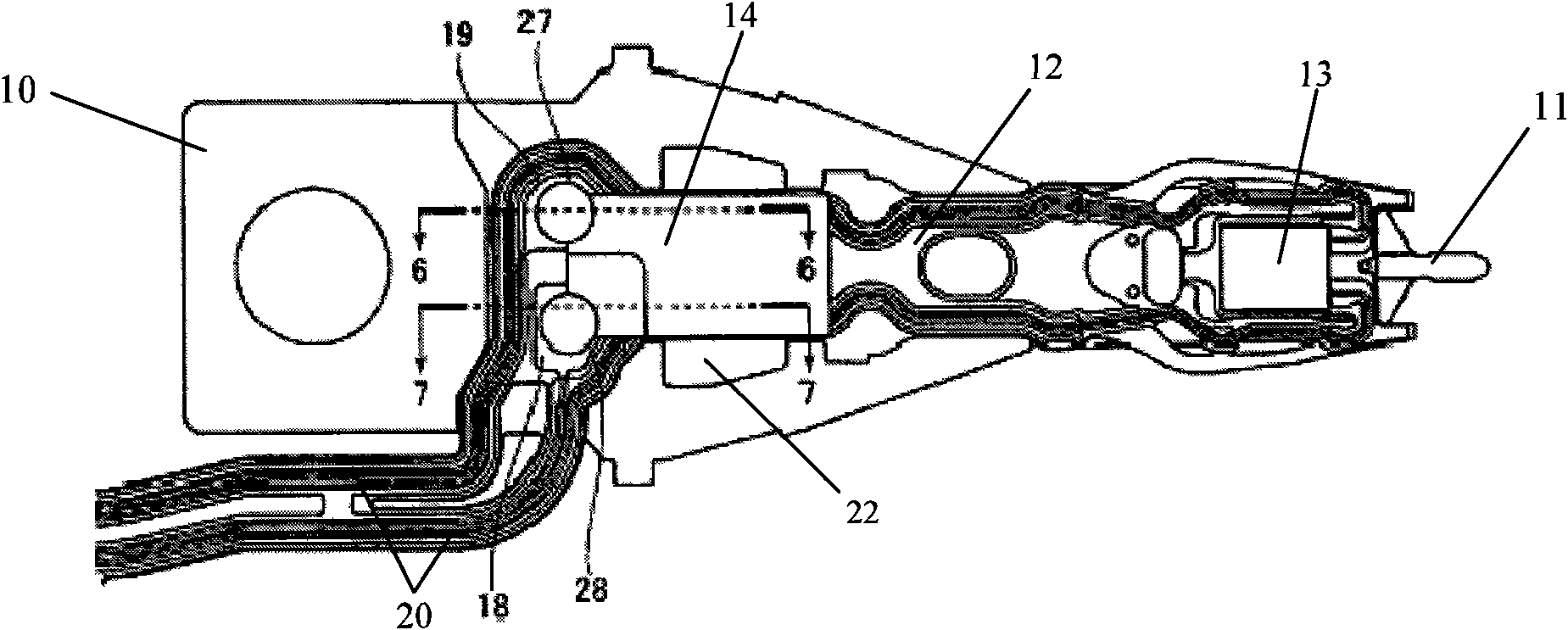

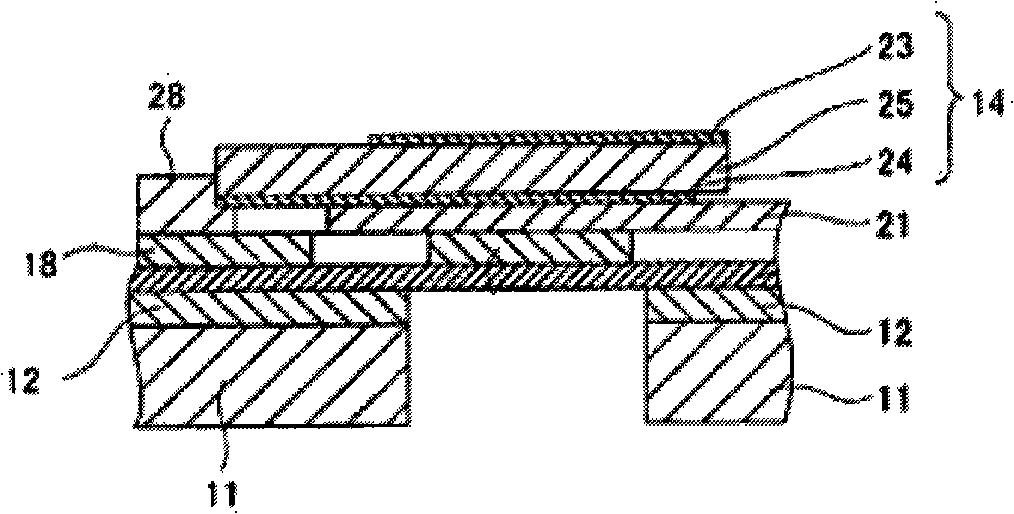

[0047] Hereinafter, various embodiments of the present invention will be described with reference to the accompanying drawings, in which the same reference numerals in the various drawings represent the same elements. As described above, the present invention provides a cantilever for a magnetic head flap assembly of a disk drive unit. The cantilever includes a vibration sensor. The vibration sensor includes a base and is formed in the base for supporting installation. The load part of the magnetic head thereon, and at least two connecting arms connecting the base part and the load part. By mounting the vibration sensor with lower rigidity on the cantilever tongue and sandwiching it between the cantilever tongue and the magnetic head, it is more sensitive to the vibration of the magnetic head, thereby improving the read and write performance of the magnetic head and the entire disk The performance of the drive unit.

[0048] Figure 4 The first embodiment of the cantilever of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com