Test device for testing performance of compliant foil gas journal bearing

A technology of radial bearings and elastic foils, which is applied in the field of test devices for testing the performance of elastic foil gas radial bearings, can solve the problems of static and dynamic performance test devices for gas radial bearings without elastic foils, and achieve test Comprehensive functions, convenient assembly and disassembly, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

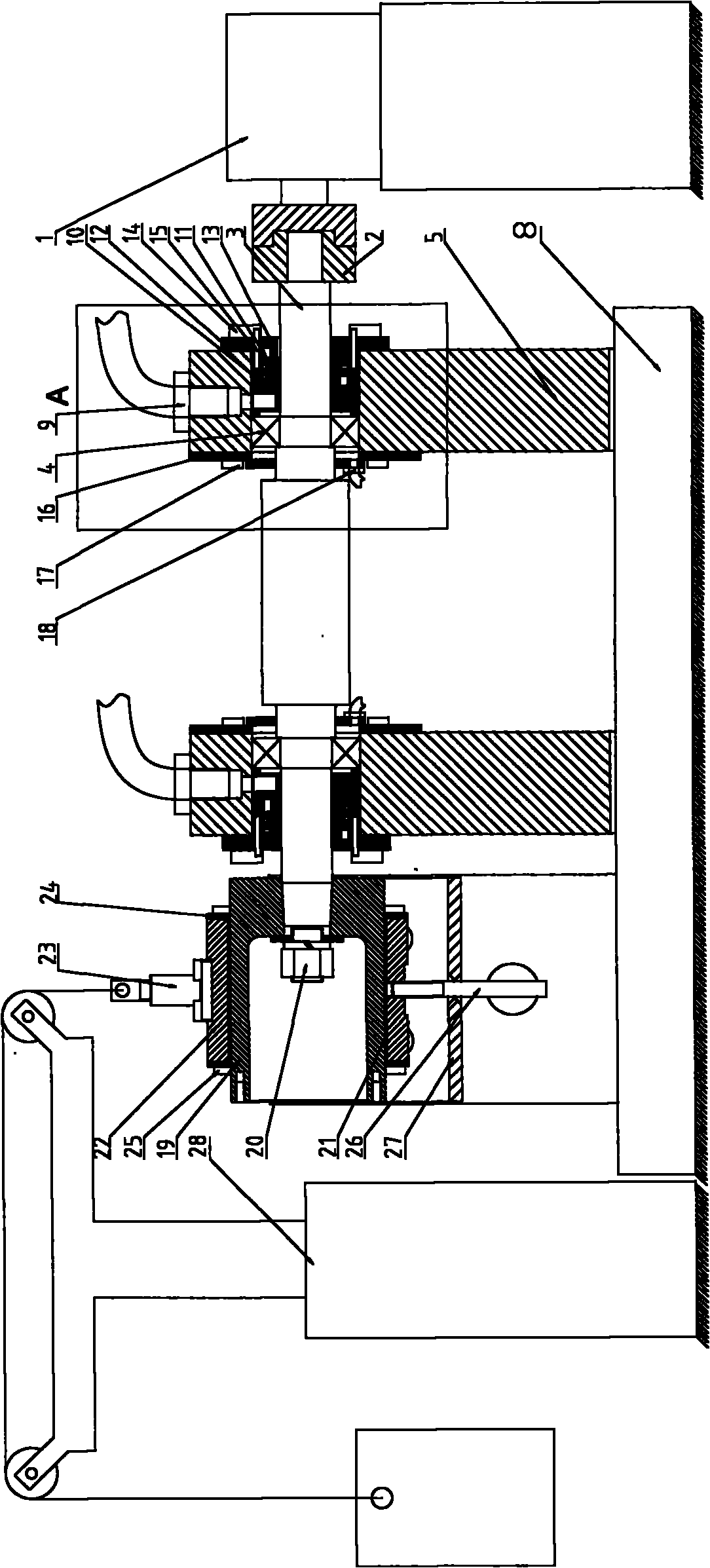

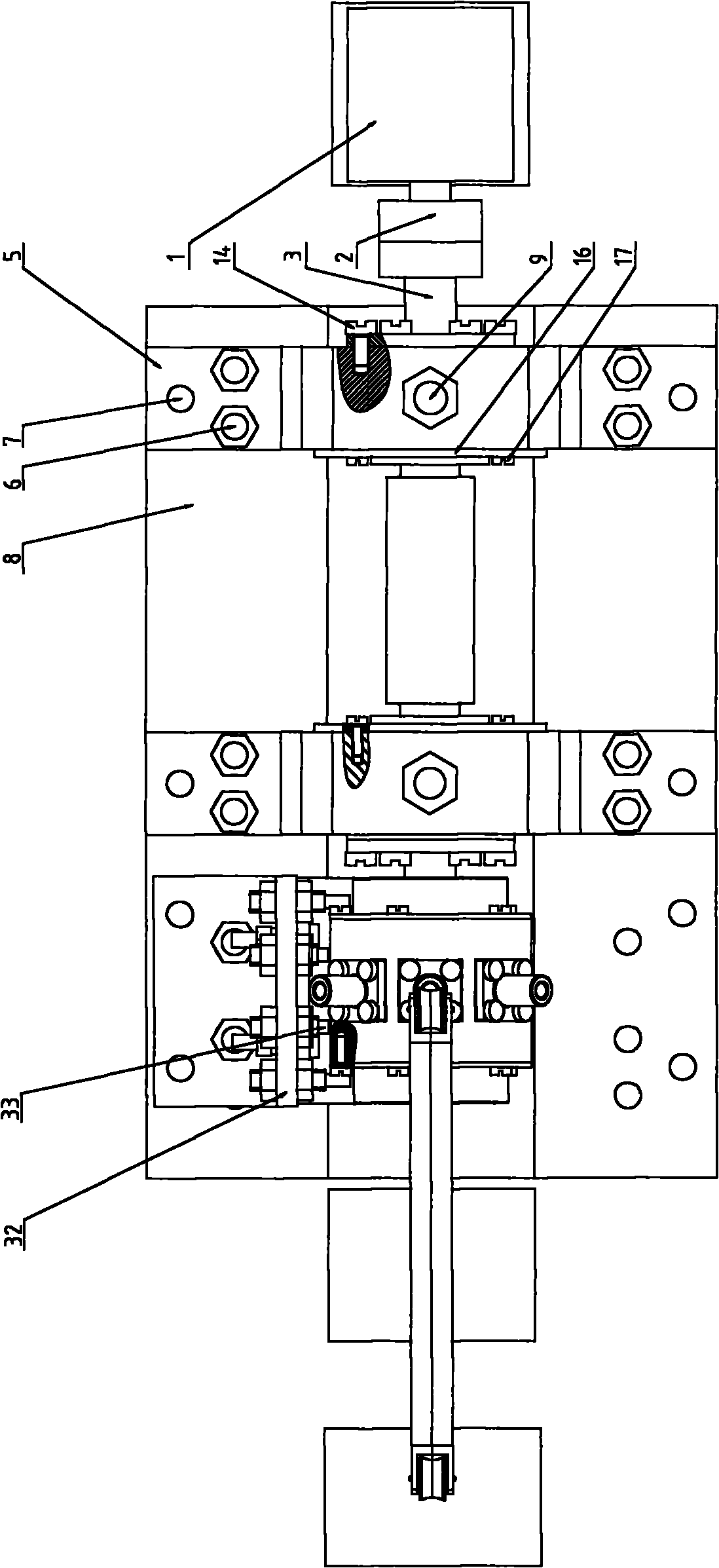

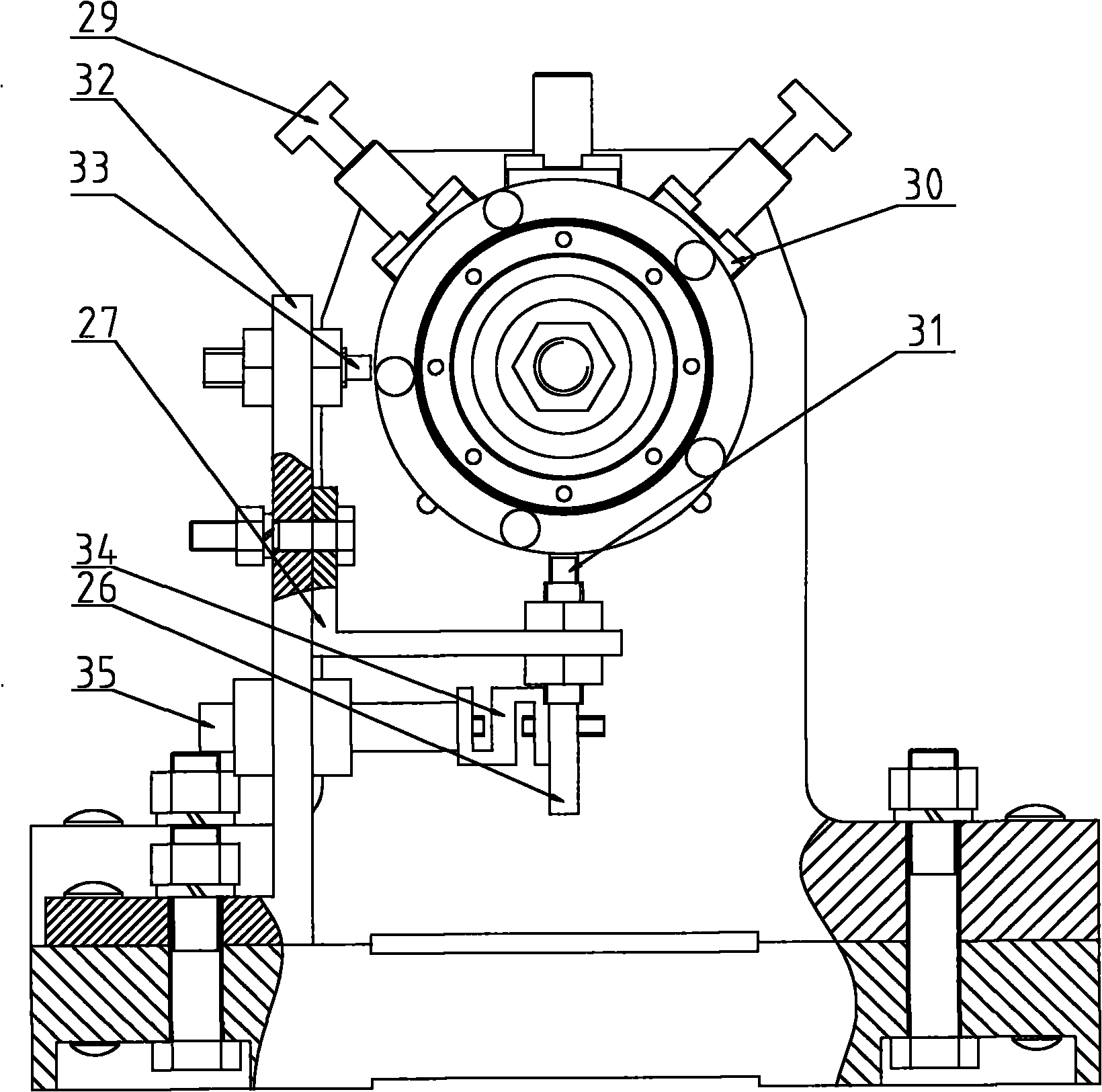

[0017] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] see figure 1 , figure 2 , image 3 and Figure 4 , a test device for testing the performance of an elastic foil gas radial bearing, comprising an asynchronous motor 1 with a frequency converter, the asynchronous motor 1 is connected to one end of a test rotor 3 through a high-speed flexible coupling 2, and the test rotor 3 has a symmetrical structure, Supported by two identical high-speed angular contact ball bearings 4, one side of the high-speed angular contact ball bearing 4 is equipped with an oil deflector ring 10, a pre-tightening spring 11, an end cover gasket 12 and a pre-tightening end cover 13, and the pre-tightening end cover is used The bolt 14 is fixed on the bearing seat 5. The high-speed angular contact ball bearing 4 is preloaded by the preload spring 11. The preload can be adjusted by the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com