Laser driven light source

A technology of laser drive and light source, which is applied to the components of gas discharge lamps, electrical components, discharge lamps, etc., which can solve the problem of low luminous intensity of mercury, inability to control the rise of 135 mercury vapor pressure, and inability to control the full evaporation of 135 mercury, etc. problem, to achieve high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

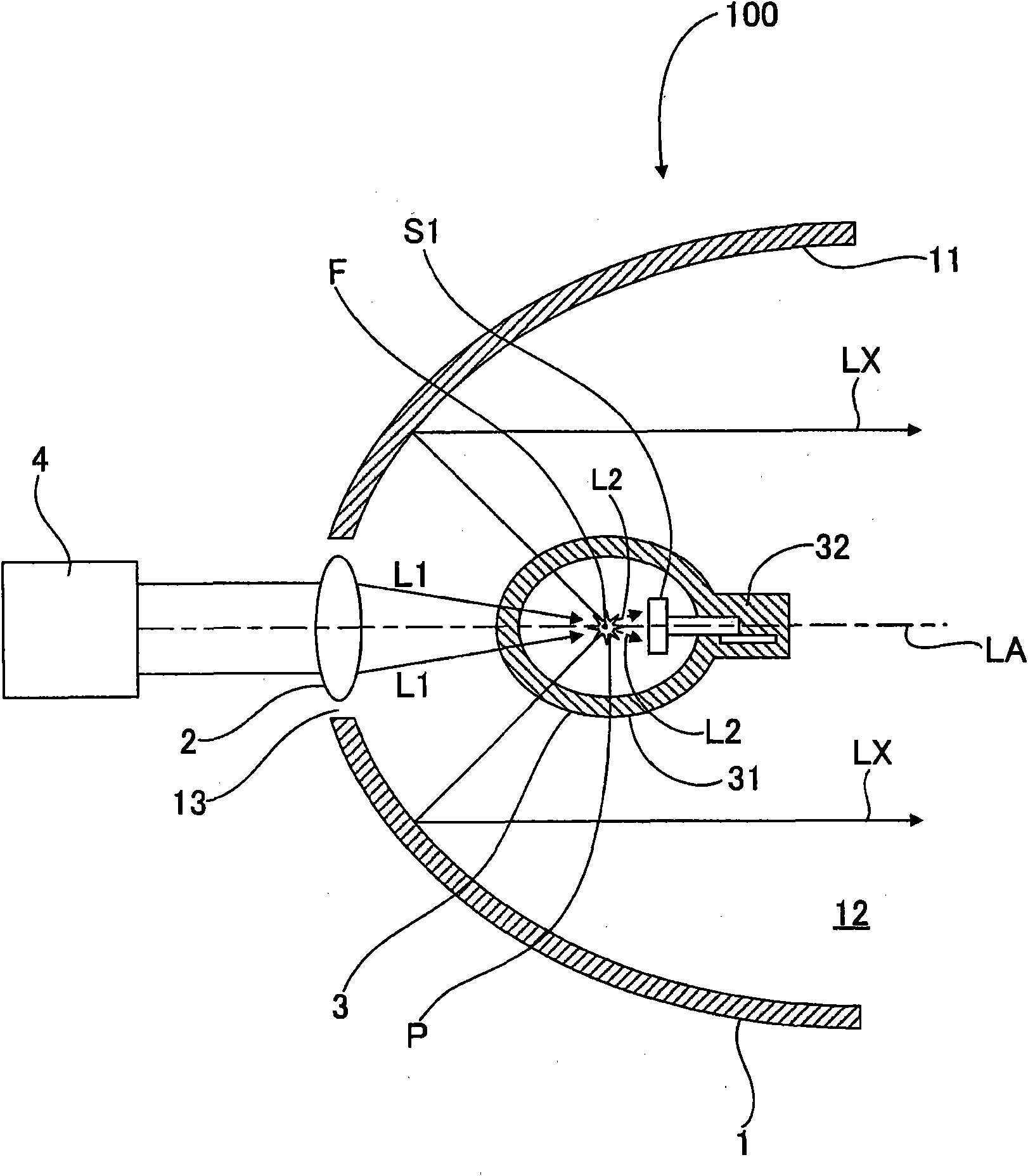

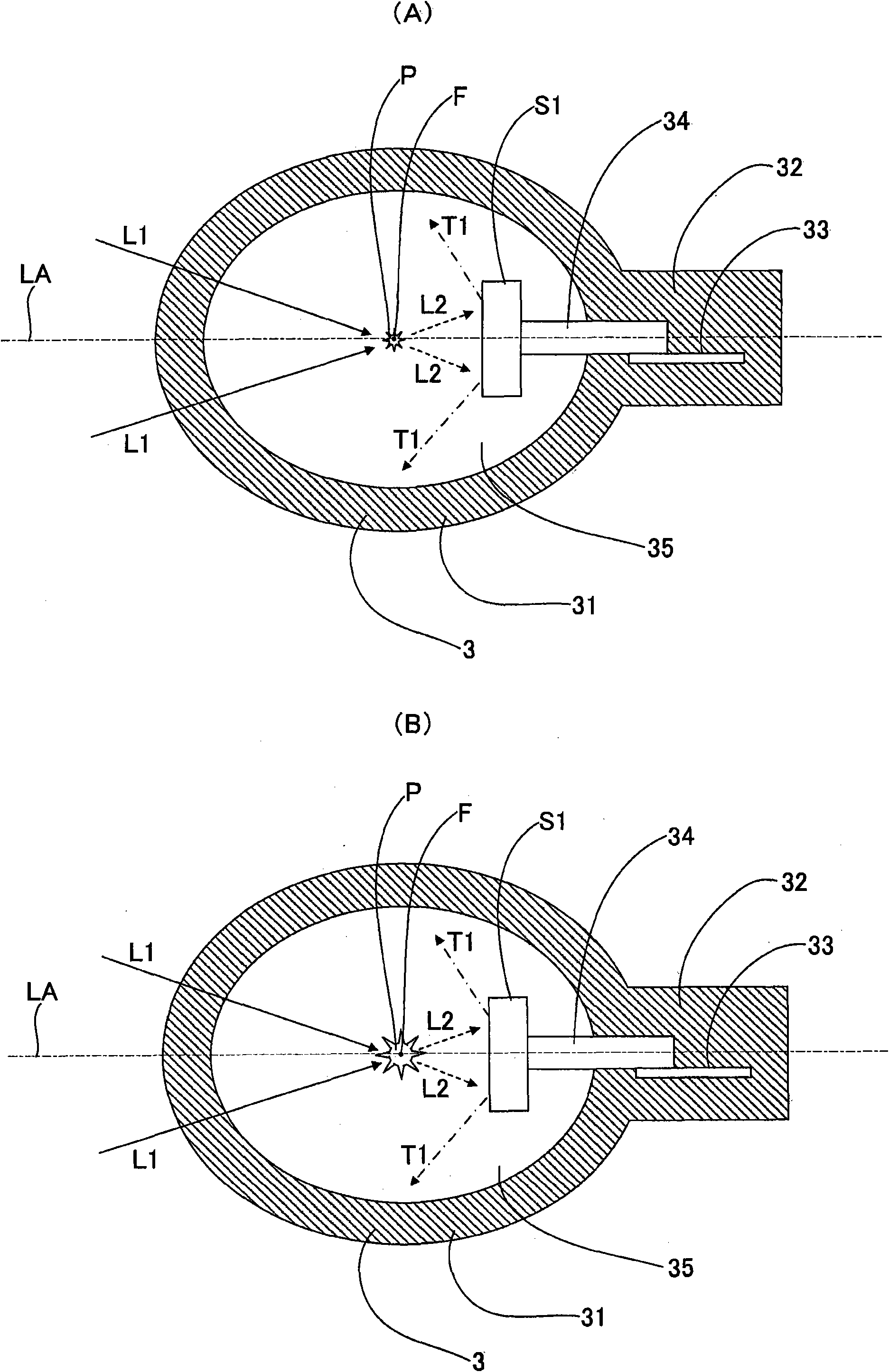

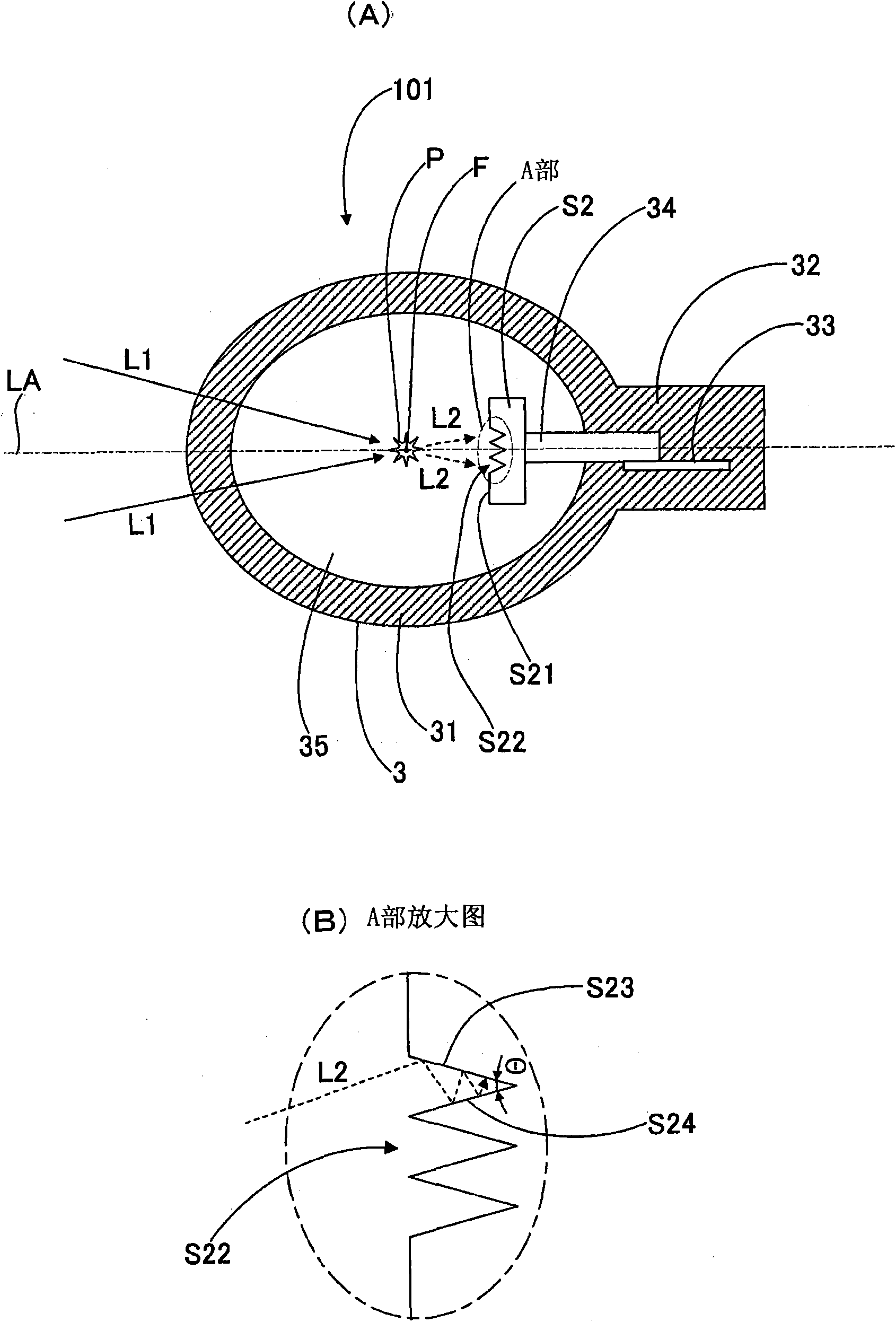

[0051] (Laser-driven light source of the first embodiment)

[0052] figure 1 It is a sectional view showing the basic configuration of the laser-driven light source according to the first embodiment of the present invention. The laser-driven light source of this embodiment is an electrodeless light source that does not have electrodes inside the bulb. Furthermore, the laser-driven light source of this embodiment has a light shielding member for shielding by absorbing laser light that has passed through the plasma without being absorbed by the plasma.

[0053] The laser-driven light source 100 has: a bowl-shaped concave reflector 1, which is configured around the bulb 3 and has a light exit opening 12; an optical system component 2, which condenses the laser light L1 to the focal point F in the bulb 3; The ball 3 is arranged to coincide with the focal point F of the concave mirror 1, and a discharge medium is sealed therein; the laser source 4 emits laser light to the tube 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com