Method and device for manufacturing metal oxide particles

A manufacturing method and particle technology, applied in chemical instruments and methods, titanium oxide/hydroxide, oxygen/ozone/oxide/hydroxide, etc., can solve the problem of low ratio of decahedral titanium oxide particles, adhesion, deca Problems such as low productivity of titanium oxide particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0047]

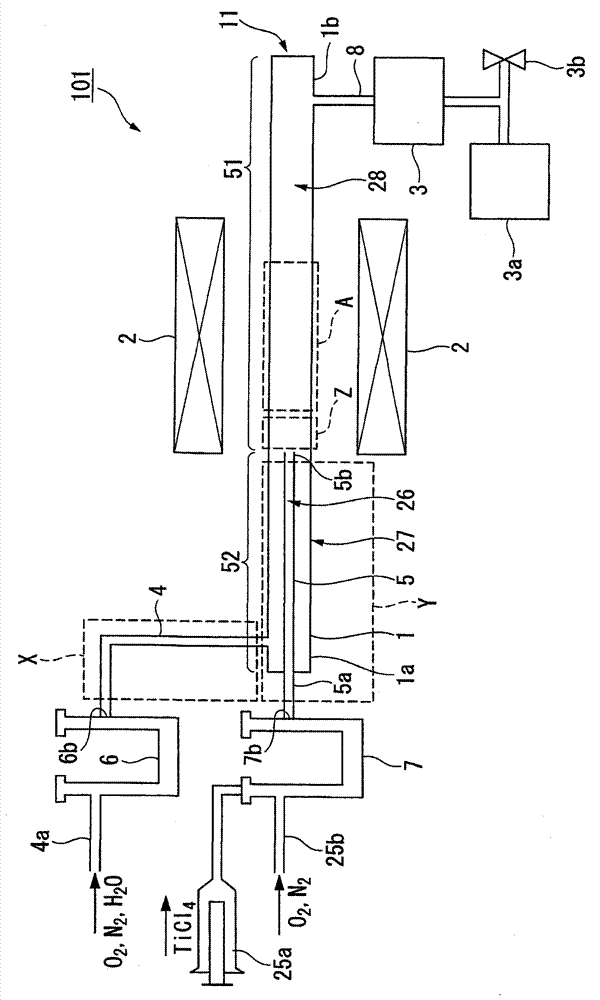

[0048] figure 1 It is a schematic diagram showing an example of an apparatus for producing metal oxide particles (decahedral titanium oxide particles) as an embodiment of the present invention. An example of the production of titanium oxide particles will be described below.

[0049] Such as figure 1 As shown, the production apparatus 101 of metal oxide particles as an embodiment of the present invention is roughly constituted by the following components: a reaction tube 11 having a hollow outer cylinder 1 and a tube inserted from the upstream side 1a of the hollow outer cylinder 1 to the middle. The double tube structure part 52 of the hollow inner tube 5 and the single tube structure part 51 containing only the hollow outer tube 1; the heating device 2 arranged outside the reaction tube 11 to locally heat the single tube structure part 51; Barrier gas introduction pipes 4, 4a connected to the upstream side 1a of the hollow outer cylinder 1; reaction gas introduc...

no. 2 Embodiment approach

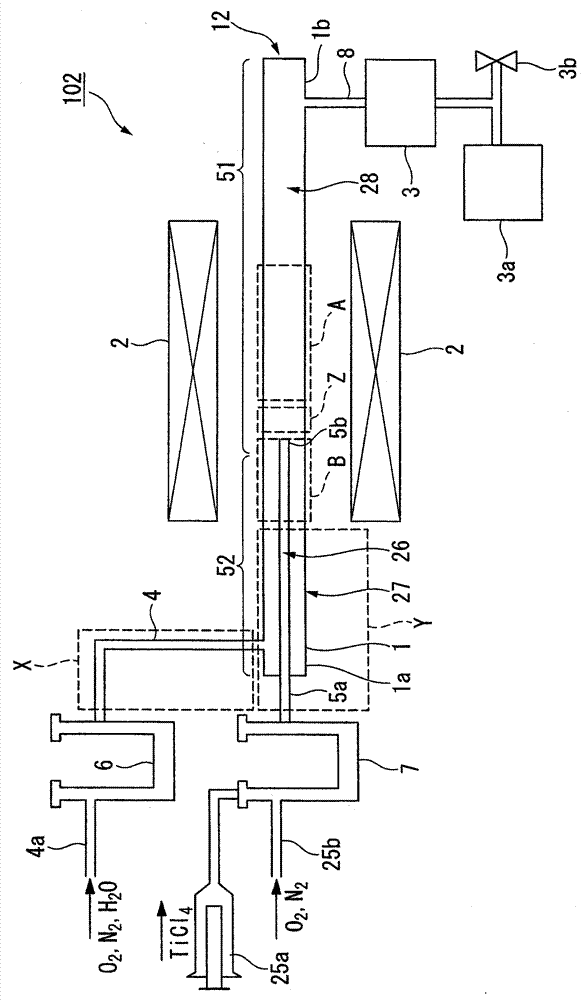

[0195] figure 2 It is a schematic diagram which shows another example of the manufacturing apparatus of the metal oxide particle (decahedral titanium oxide particle) which is embodiment of this invention. The same symbols are used for the same components as those shown in the first embodiment.

[0196] Such as figure 2 As shown, as the manufacturing device 102 of metal oxide particles according to the embodiment of the present invention, the downstream end portion 5b of the hollow inner cylinder 5 is greatly extended into the region sandwiched by the two heating devices (infrared gold furnace) 2. The hollow inner cylinder 5 is configured in a manner. Another preheating zone B is formed between the downstream end of the preheating zone Y and the position of the downstream end portion 5b by wrapping the hollow outer cylinder 1 with a platinum plate (not shown). In addition, other configurations are the same as those of the metal oxide particle manufacturing apparatus 101 de...

Embodiment 1

[0209] use figure 1 The metal oxide particle production apparatus 101 shown produces titanium oxide particles in the following manner.

[0210] First, a quartz tube with an outer diameter of 25.0mm, an inner diameter of 21.0mm, and a thickness of 2.0mm was used as the hollow outer cylinder 1, and a quartz tube with an outer diameter of 12.7mm, an inner diameter of 10.0mm, and a thickness of 1.3mm was used as the hollow inner cylinder 5, and a hollow outer cylinder was produced. A reaction tube 11 of a double-tube structure in which the cylinder 1 and the hollow inner cylinder 5 are arranged coaxially. Thus, the cross-sectional area of the annular opening is 2.6 times the cross-sectional area of the opening of the inner cylinder, and the cross-sectional area of the opening of the outer cylinder is 4.09 times the cross-sectional area of the opening of the inner cylinder.

[0211] Next, a 16 cm platinum plate was wound around a part of the reaction tube 11, and the heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com