Method for manufacturing dental implantation surgical guide plate

A technique for surgical guidance and manufacturing method, which is applied in the directions of dental implants, prosthetics, dentistry, etc., and can solve the problems of poor manufacturing efficiency, high manufacturing cost, and low accuracy of the guide plate 11 , etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

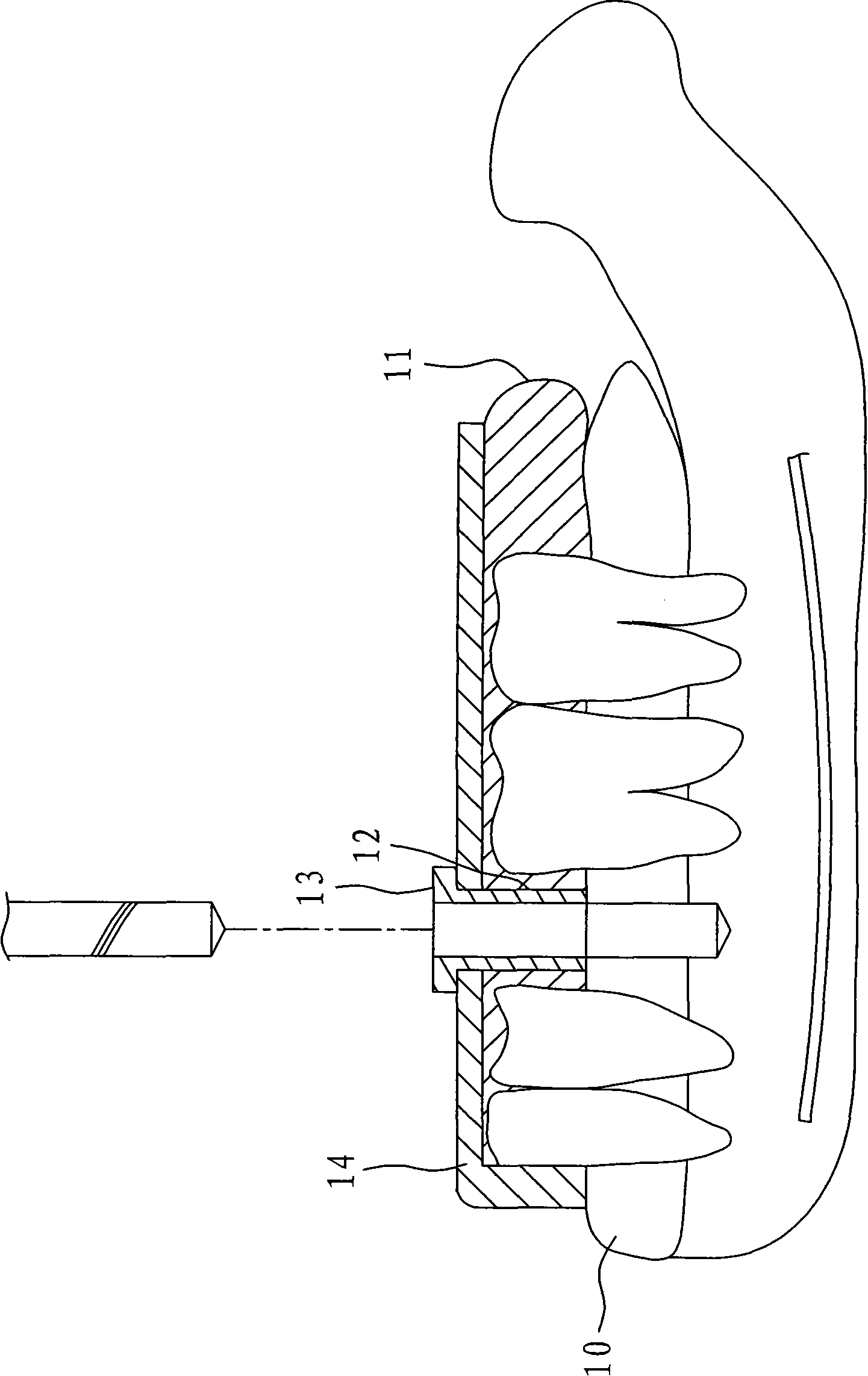

[0075] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, below in conjunction with the drawings and preferred embodiments, the method for making the guide plate for dental implant surgery proposed according to the present invention, its specific implementation, The method, steps, features and effects thereof are described in detail below.

[0076] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

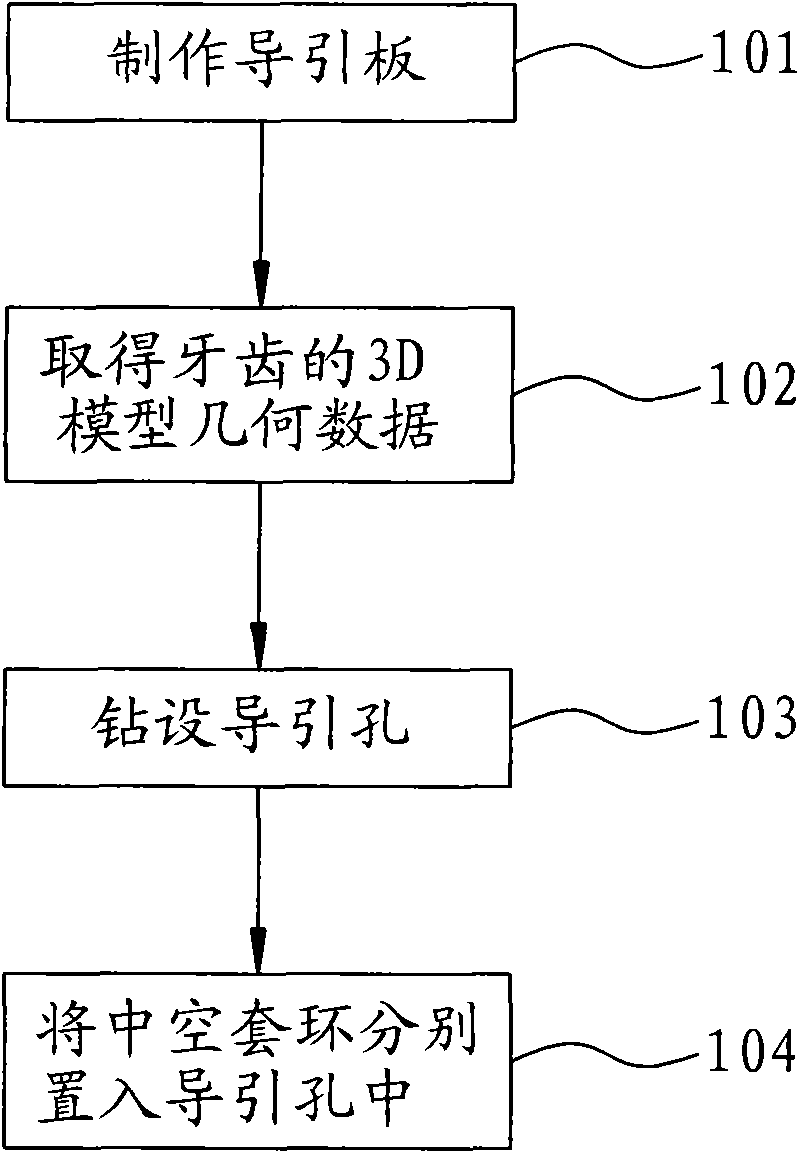

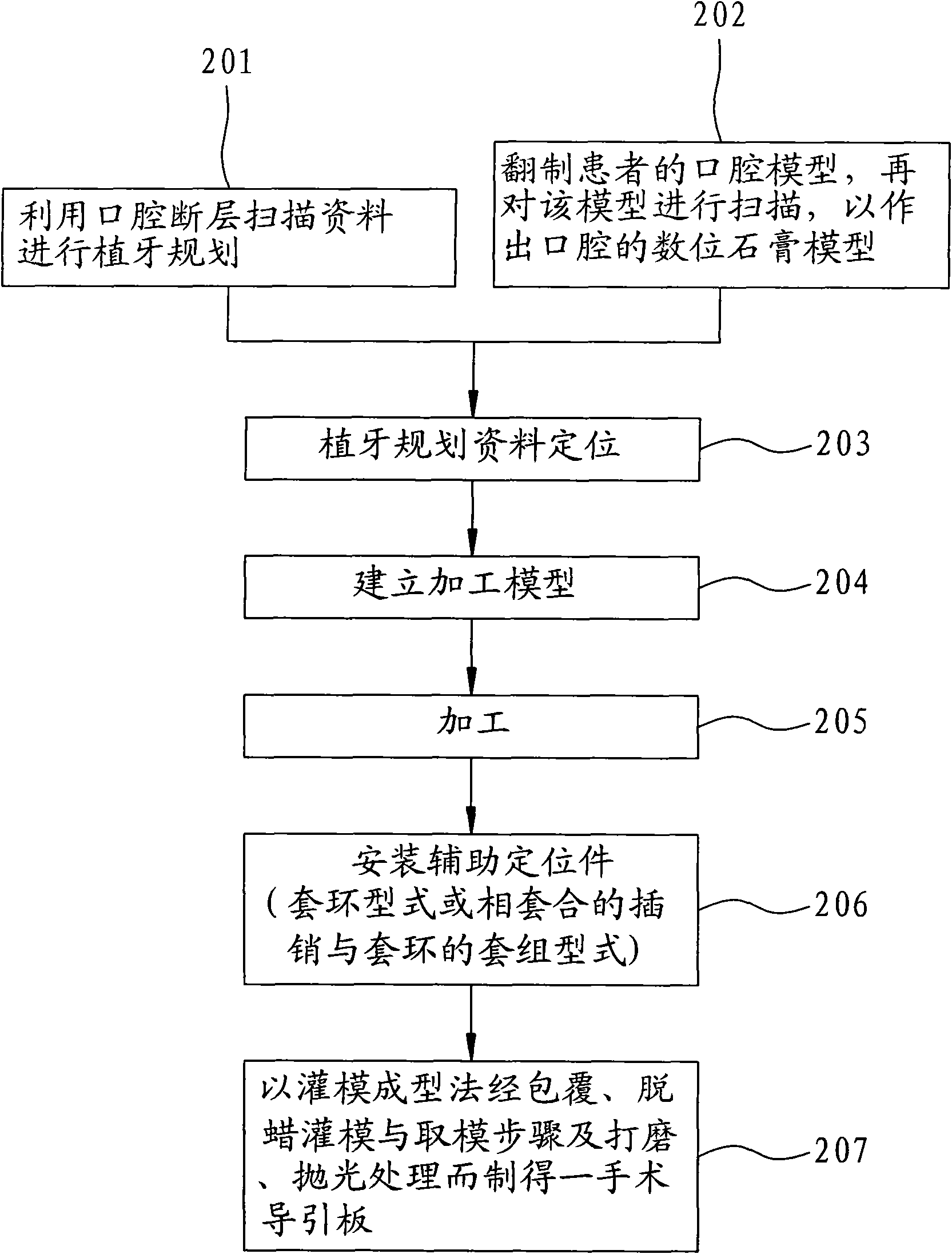

[0077] see image 3 , a first preferred embodiment of the manufacturing method of the dental implant surgery guide plate of the present invention comprises the following steps:

[0078] Step 201 is dental implant planning, using the dentist to plan the dental implant on the 3D stereoscopic model obtained after the patient's oral cavity tomography, and obtain and build a digital mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com