Production process of spinning handrail

A production process and technology of spinning bicycles, which are applied in sports accessories, training equipment for adjusting coordination, and devices for coating liquid on the surface, etc. Long life and good feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

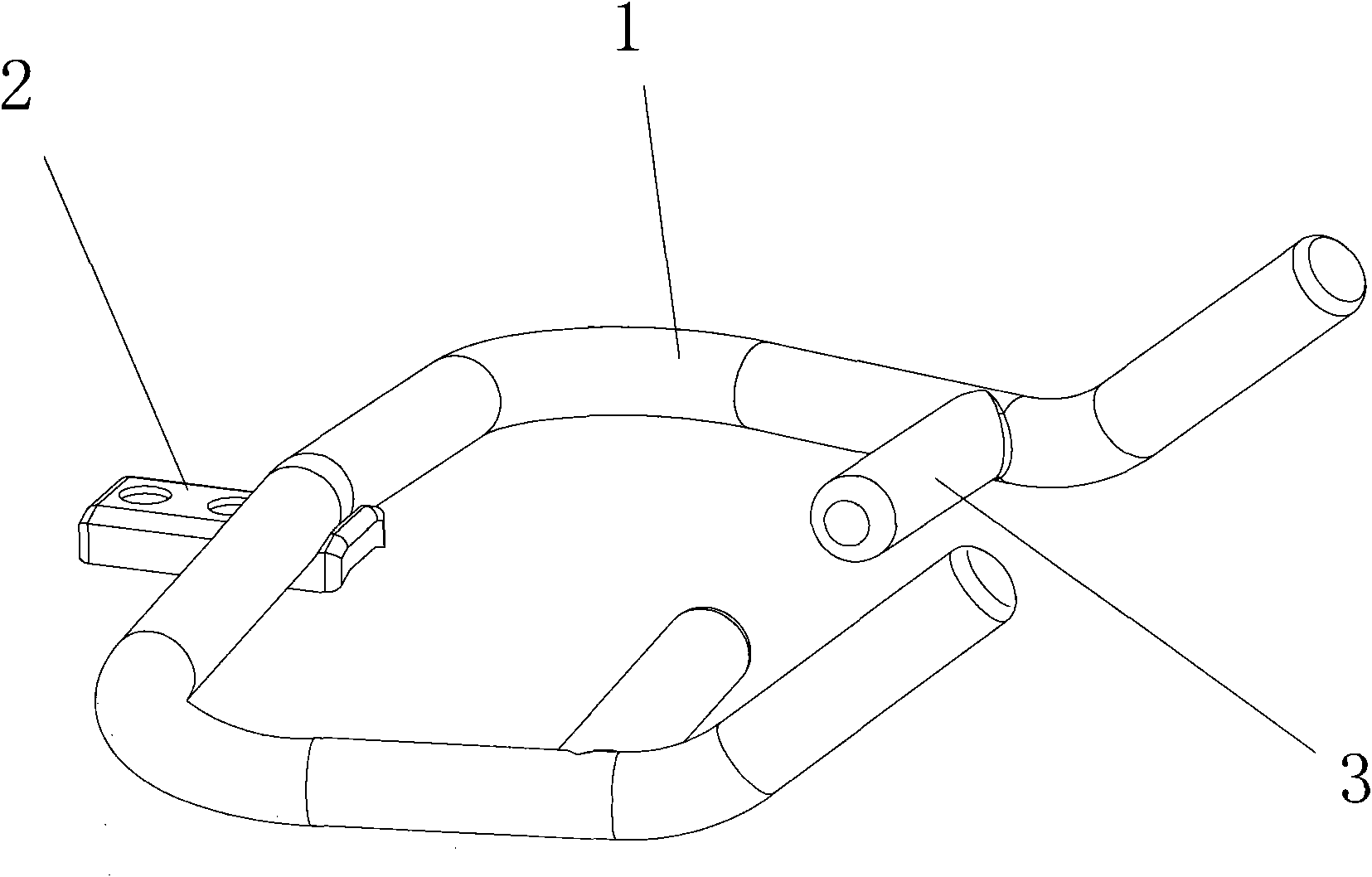

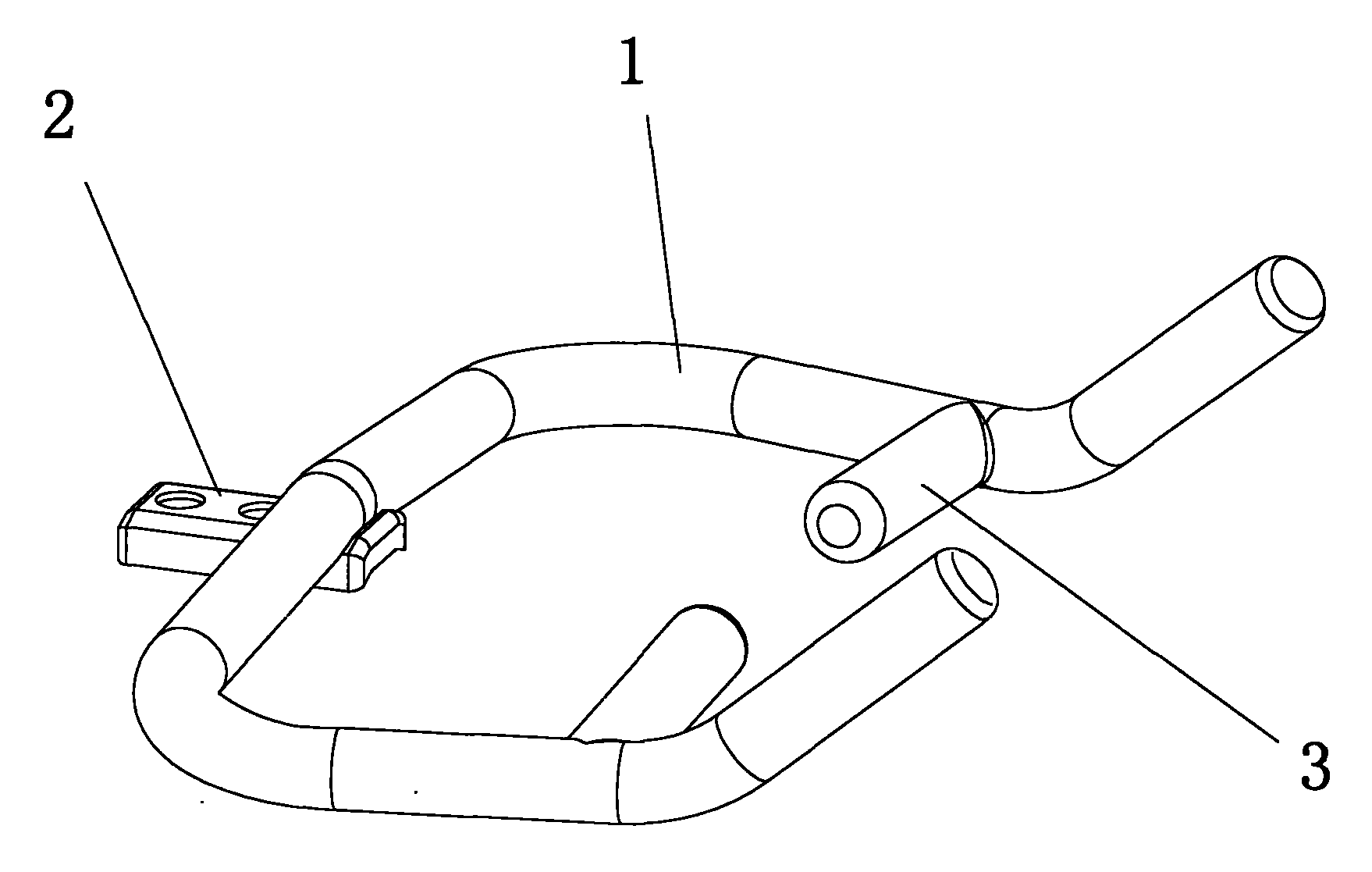

[0016] refer to figure 1 , a production process for spinning handrails, which mainly includes the following steps: first, the metal worker chooses Q235 ordinary steel pipe as the base structure, and cuts the material according to the length given on the drawing (the equipment used is a sawing machine)——after the pipe is sawed Metalworking for pipe bending (a total of two bends, the equipment used is a pipe bender) - after two bends are bent, punching and forming (punching machine) - punching as required (punching machine) - grinding the surface of the handrail tube De-stabbing treatment;——Weld the handrail pipe 1, the handrail fixing piece 2, and the handle pipe plug 3 with the pre-made fixtures to form a semi-finished handrail (the fixture must be clamped in place, and all pressing hands must use upper clamps Tight)——Welding and correcting the semi-finished handrails to avoid uneven height of the handrails;——Degreasing (using alkaline degreasing powder)—Washing—Pickling (30% ...

Embodiment 2

[0018] The pre-baking temperature is 320° C., and the time is 20 minutes. The curing temperature is 180° C., and the time is 14 minutes. Others are the same as in Example 1.

Embodiment 3

[0020] The pre-baking temperature is 370° C., and the time is 14 minutes. The curing temperature is 200° C., and the time is 6 minutes. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com