Pretreating system of garbage classification

A technology for sorting garbage and flushing water tanks, applied in the field of mechanical devices, can solve problems such as slow speed and low efficiency, achieve high efficiency, good treatment effect, and liberate labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

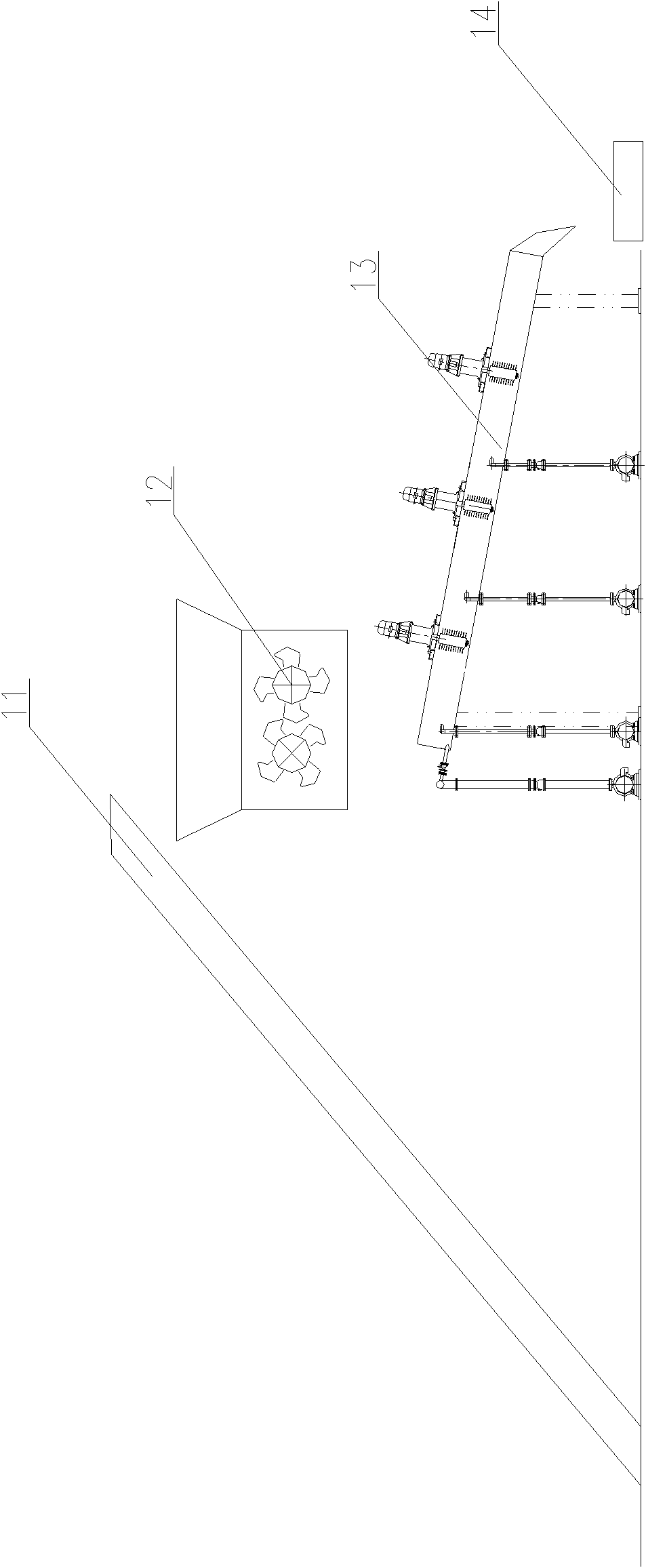

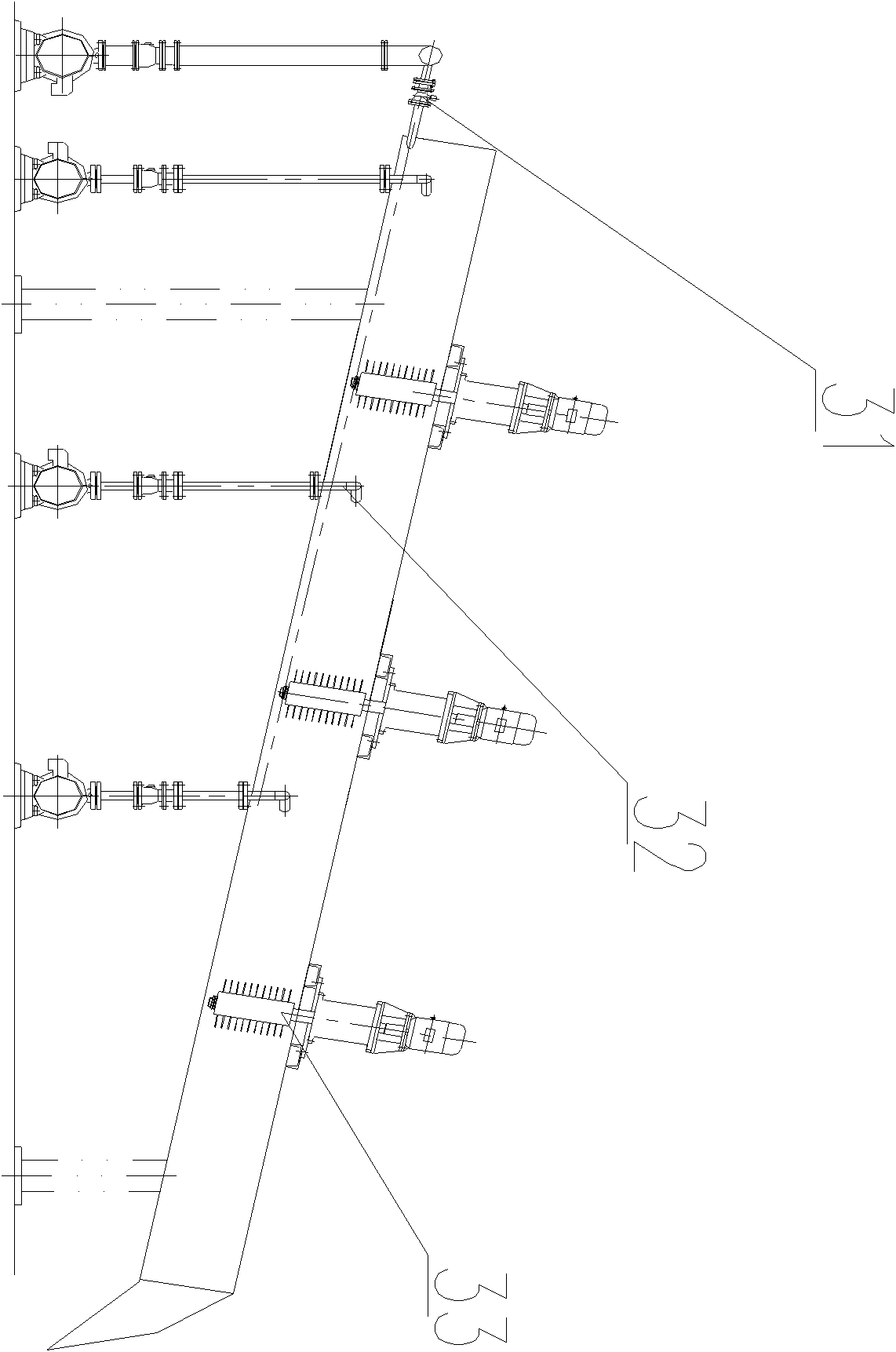

[0016] For a better understanding and description of the present invention, with Figure 1~4 The illustrated embodiment is described in detail.

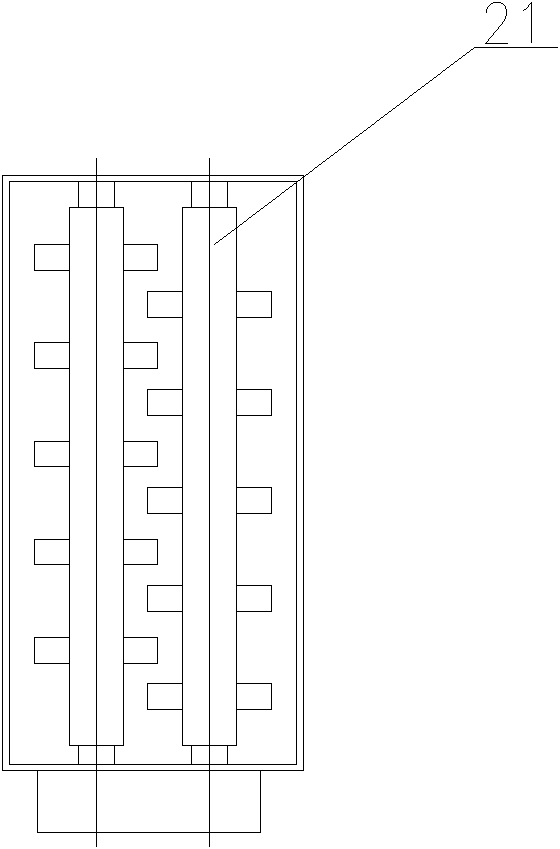

[0017] Such as figure 1 , embodiment of the present invention, conveyor belt 11 connects ground to high coarse crushing device 12, and coarse crushing device 12 is arranged on the top of the higher front end of flushing water tank 13, and flushing water tank 13 has certain drop, and lower rear end is connected with Output conveyor belt 14. The coarse crushing device 12 is cylindrical, and the conveyor belt transports the garbage to be processed into the upper opening of the coarse crushing device 12, crushed and crushed by the rotating rolling teeth 21 inside it, and falls into the flushing water tank 13 from the lower opening.

[0018] Such as figure 1 and figure 2 1. A pair of rotating rolling teeth 21 are arranged in the coarse crushing device 12. The rotating shaft is fixed on the side of the crushing device, and a protrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com