Process for preparing collagen tripeptide

A collagen tripeptide and a preparation process technology, which are used in skin care preparations, cosmetics, fermentation and other directions to achieve the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

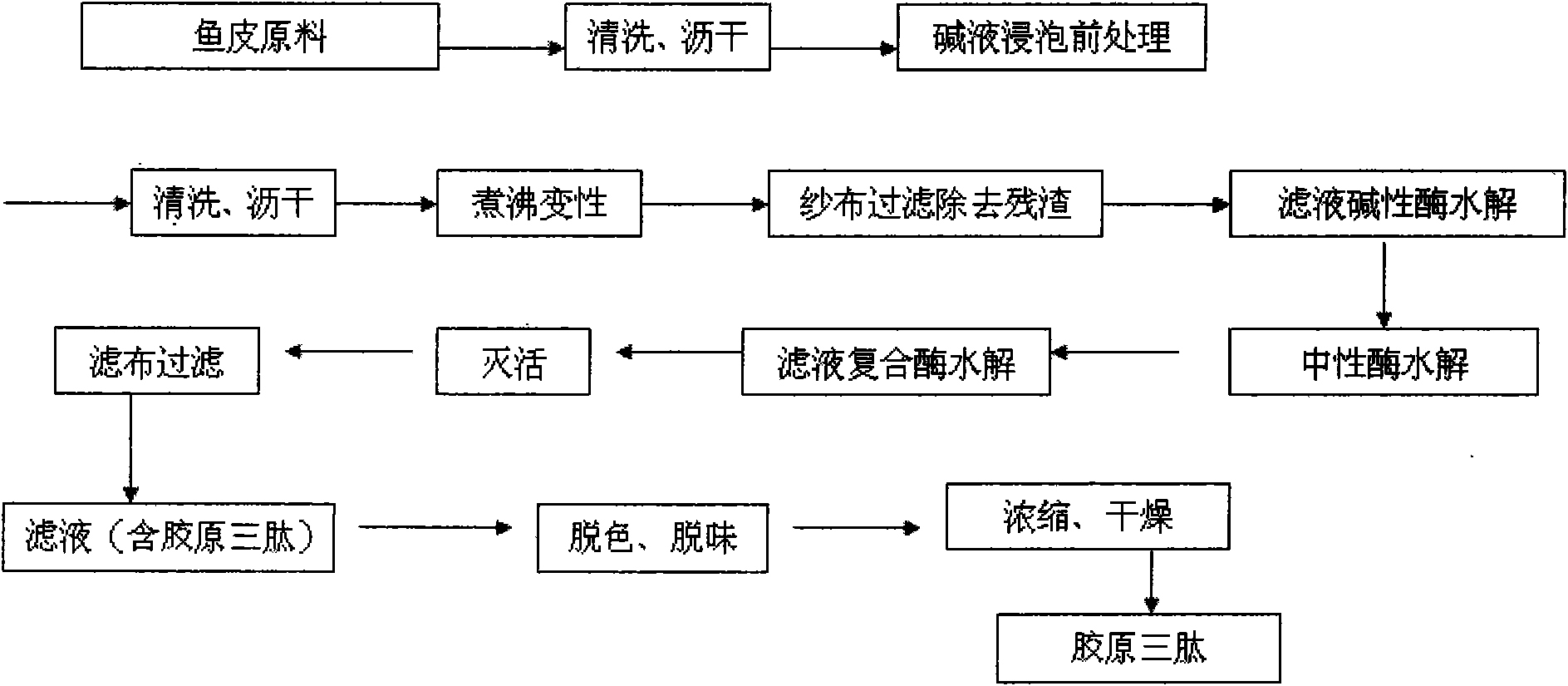

Method used

Image

Examples

Embodiment 1

[0046] Feeding 50kg of lye (1.0% calcium hydroxide) and soaking the tilapia skins cleaned and drained for 1 day, adding 250L of water, boiling and denaturing for 30min, filtering the filtrate through gauze, cooling to about 50°C, adding 0.25kg of alkaline protease, Hydrolyze at 55°C for 1 hour, add 0.25 kg of neutral protease, hydrolyze for 1 hour, add 0.25 kg of compound protease, hydrolyze for 1 hour, steam inactivate the enzyme for 10 minutes; collect about 270 L of filtrate by filter cloth, pass through a carbon column, and finally concentrate and spray dry to obtain collagen III Peptide 5.1 kg.

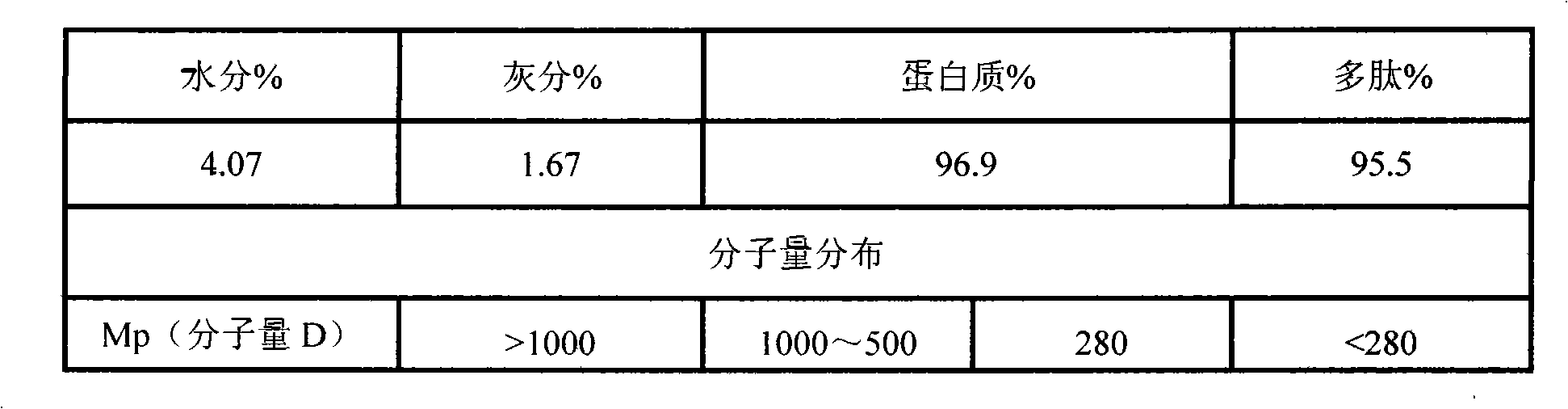

[0047] Prepared collagen tripeptide product index is as follows:

[0048] Molecular weight range

Embodiment 2

[0050]Feeding 60kg of lye (1.0% calcium hydroxide) and soaking the tilapia skins cleaned and drained for 1 day, adding 360L of water, boiling and denaturing for 30min, collecting the filtrate by gauze filtration, cooling to about 60°C, adding 0.60kg of alkaline protease, Hydrolyze at 60°C for 1 hour, add 0.60 kg of neutral protease, hydrolyze for 1 hour, add 0.60 kg of compound protease, hydrolyze for 1 hour, steam inactivate the enzyme for 10 minutes; collect about 400 L of filtrate by filter cloth, pass through a carbon column, and finally concentrate and spray dry to obtain collagen III Peptide 6.3kg.

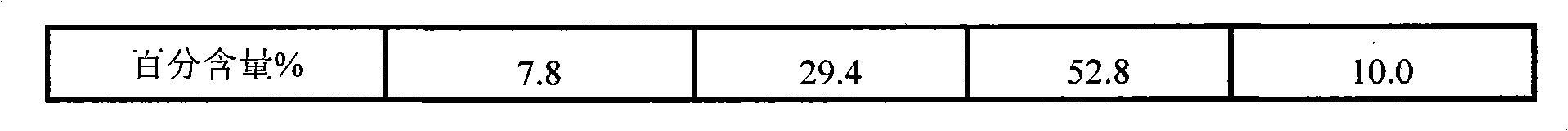

[0051] Prepared collagen tripeptide product index is as follows:

[0052] Molecular weight range

Embodiment 3

[0054] Feeding 55kg of lye (1.0% calcium hydroxide) soaked for 1 day to clean and drain the tilapia skin, add 330L of water, boil and denature for 35min, collect the filtrate by gauze filtration, cool to about 50°C, add 0.275kg of alkaline protease, Hydrolyze at 50°C for 1 hour, add 0.275 kg of neutral protease, hydrolyze for 1 hour, add 0.275 kg of compound protease, hydrolyze for 1 hour, steam inactivate the enzyme for 10 minutes; collect about 360 L of filtrate by filter cloth, pass through a carbon column, and finally concentrate and spray dry to obtain collagen III Peptide 5.7kg.

[0055] Prepared collagen tripeptide product index is as follows:

[0056] Molecular weight range

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap