A kind of cement grinding aid and preparation method thereof

A cement grinding aid and xylene technology, applied in the field of cement additives, can solve problems such as poor adaptability to process conditions, poor product quality stability, and single components, so as to promote the increase of cement output, broaden the types of raw materials, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

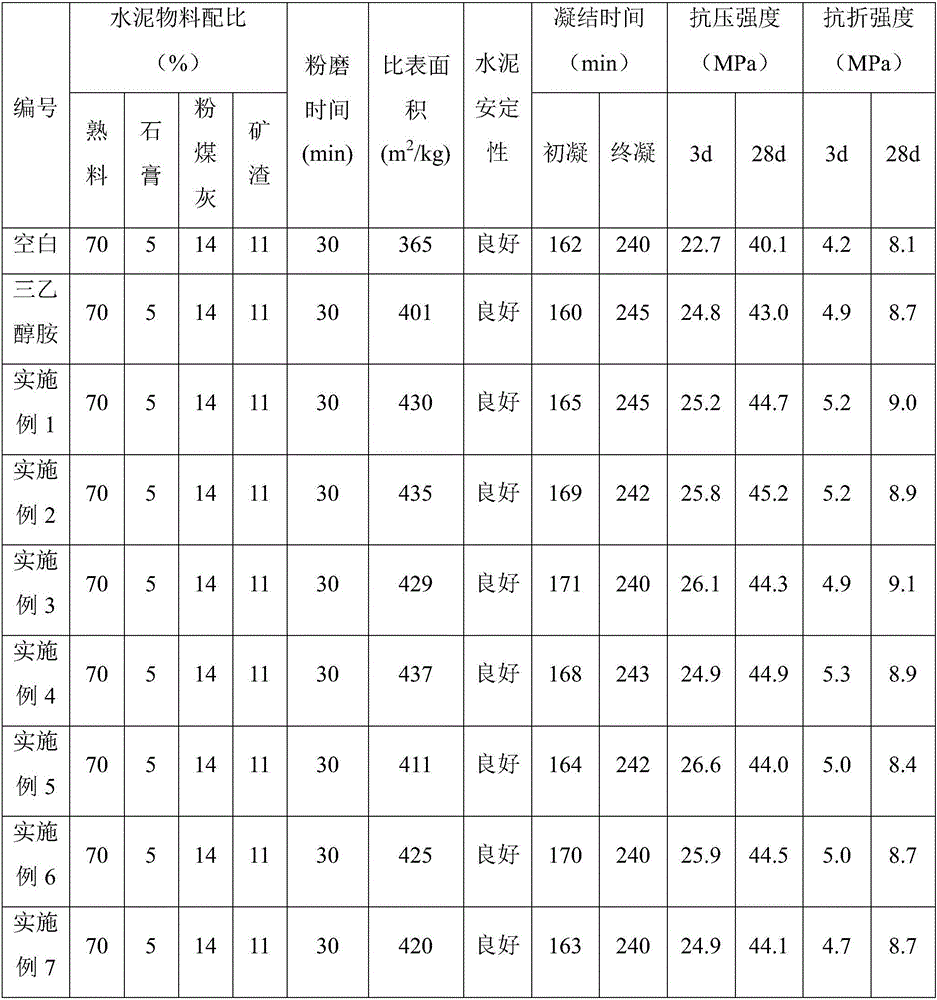

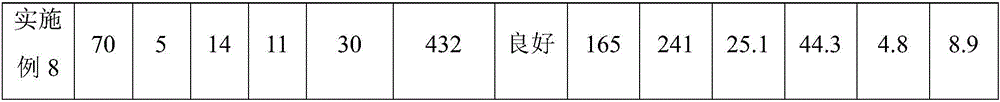

Examples

Embodiment 1

[0015] Embodiment 1: a kind of preparation method of cement grinding aid is realized through the following steps:

[0016] Put triethanolamine, n-octanoic acid, toluene and sulfamic acid in a molar ratio of 1.0:1.0:1.0:0.02 in a round-bottomed flask, under N 2 Under protection, the reaction was carried out under stirring conditions, the reaction temperature was controlled at 120 ° C, and the reaction was carried out for 6 hours. The water generated by the reaction was evaporated, and the residue was the crude product; the crude product obtained after vacuum distillation was sequentially washed with saturated Na 2 CO 3 The solution was washed with distilled water to remove unreacted octanoic acid and triethanolamine, and finally the toluene was evaporated by a rotary evaporator to obtain the final product.

Embodiment 2

[0018] A preparation method of cement grinding aid is realized through the following steps:

[0019] Place triethanolamine, myristic acid, xylene and hypophosphite in a round-bottomed flask with a molar ratio of 1.0:1.2:1.2:0.02 under N 2 Protection, heating reaction under stirring conditions, the reaction temperature is controlled at 130 ° C, the reaction is 7h, the water generated by the reaction is evaporated, and the residue is the crude product; the crude product obtained after vacuum distillation is sequentially passed through saturated Na 2 CO 3 The solution was washed with distilled water to remove unreacted myristic acid, and finally the xylene was evaporated to obtain the final product.

Embodiment 3

[0021] A preparation method of cement grinding aid is realized through the following steps:

[0022] A solution of triethanolamine, palmitic acid, xylene and p-toluenesulfonic acid in a molar ratio of 1.0:1.6:1.5:0.03 was placed in a round bottom flask under N 2 Under protection, the heating reaction was carried out under stirring conditions, the reaction temperature was controlled at 160 ° C, and the reaction was carried out for 8 hours. The water generated by the reaction was evaporated, and the residue was the crude product; the crude product obtained after vacuum distillation was sequentially passed through saturated Na 2 CO 3 The solution was washed with distilled water to remove unreacted palmitic acid, and finally the xylene was evaporated by a rotary evaporator to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com