System and method for detecting form and position tolerance of components

A technology of shape tolerance and detection method, which is applied in the direction of measuring devices, image data processing, instruments, etc., can solve the problems of time-consuming and laborious, inconvenient detection methods, and inability to provide accurate data, so as to improve detection speed and accuracy, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

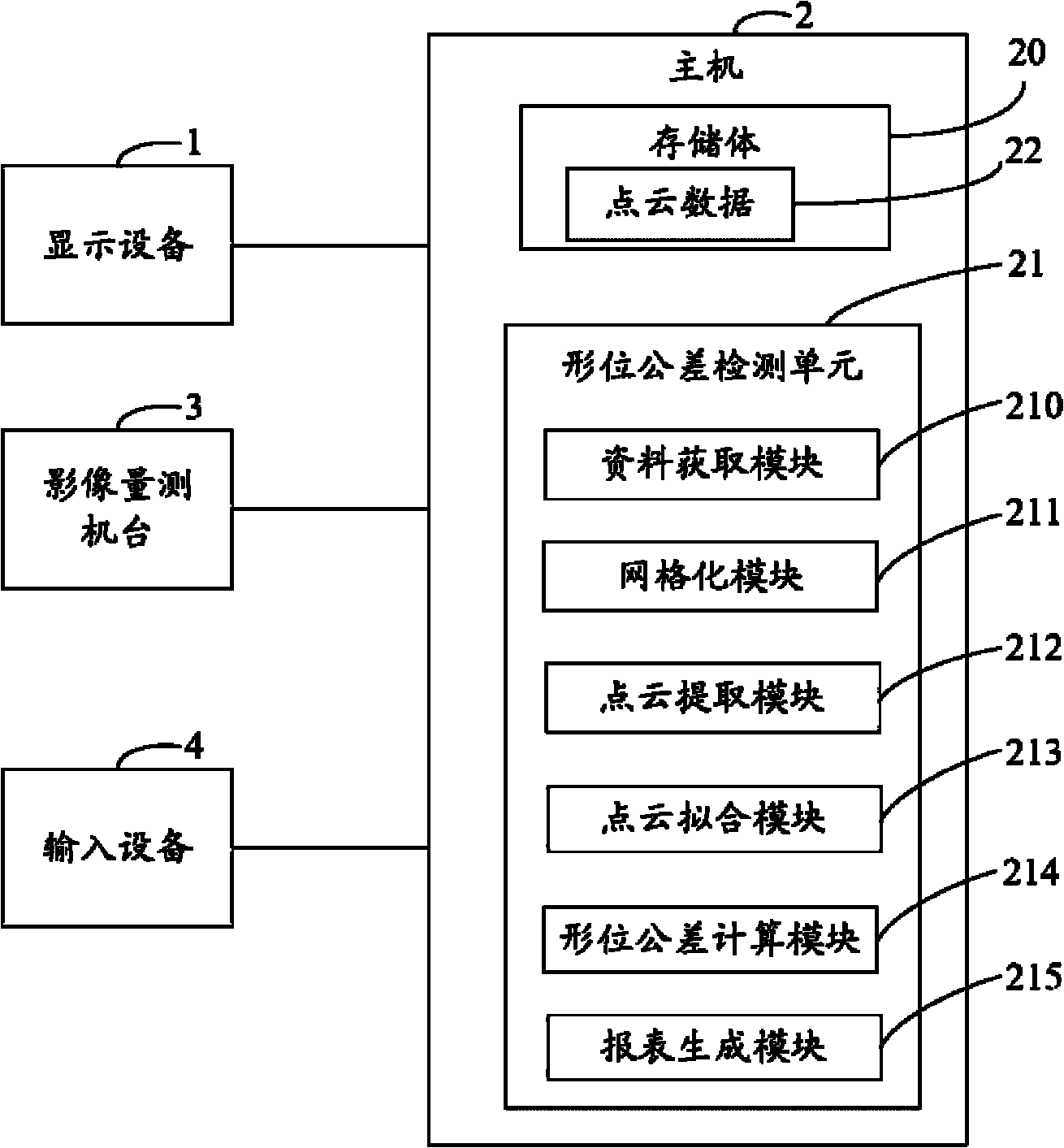

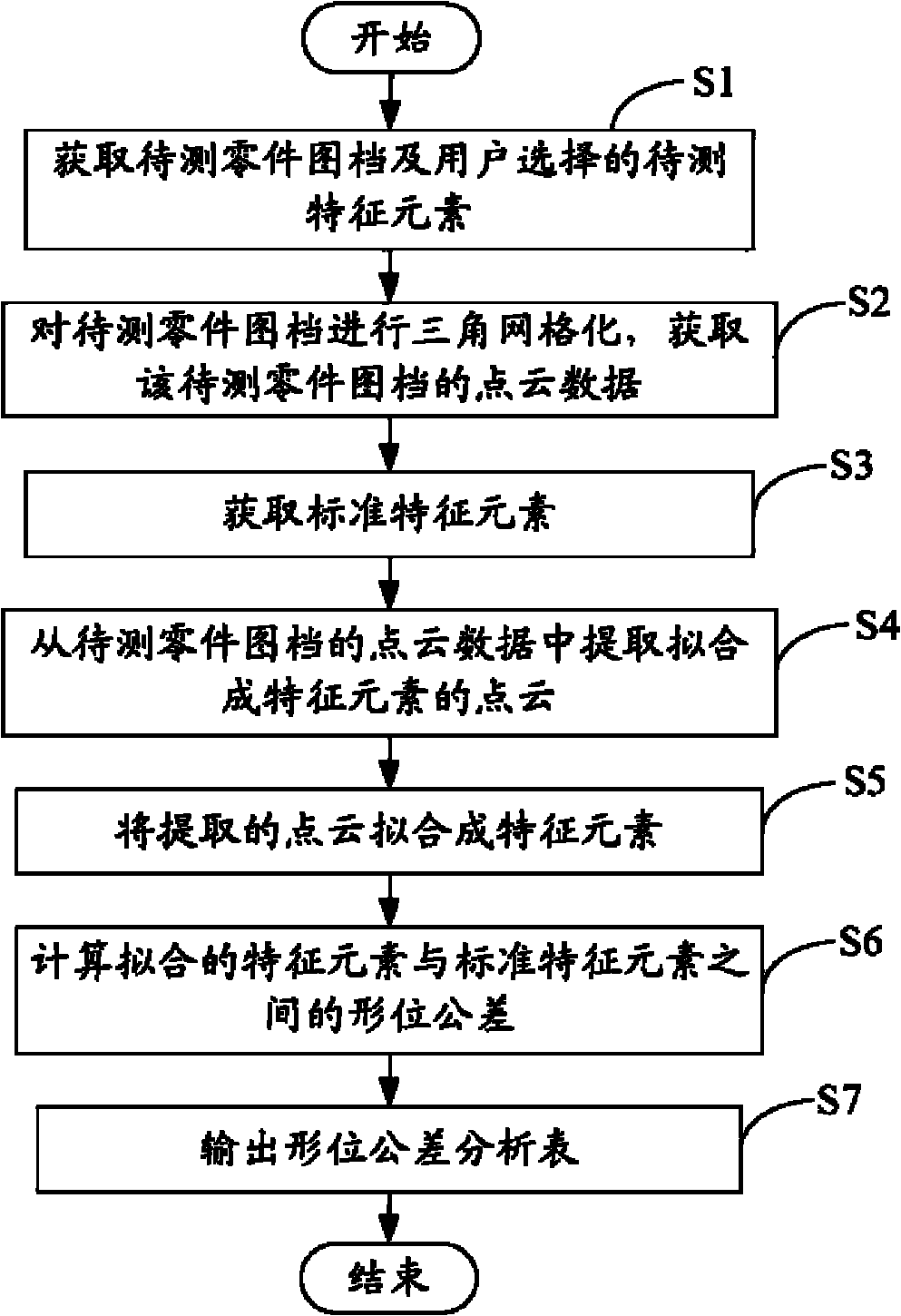

[0015] like figure 1 Shown is a system architecture diagram of a preferred embodiment of the part shape and position tolerance detection system of the present invention. The system mainly includes a display device 1 , a host computer 2 , an image measuring machine 3 and an input device 4 . The host 2 includes a storage body 20 and a shape tolerance detection unit 21 .

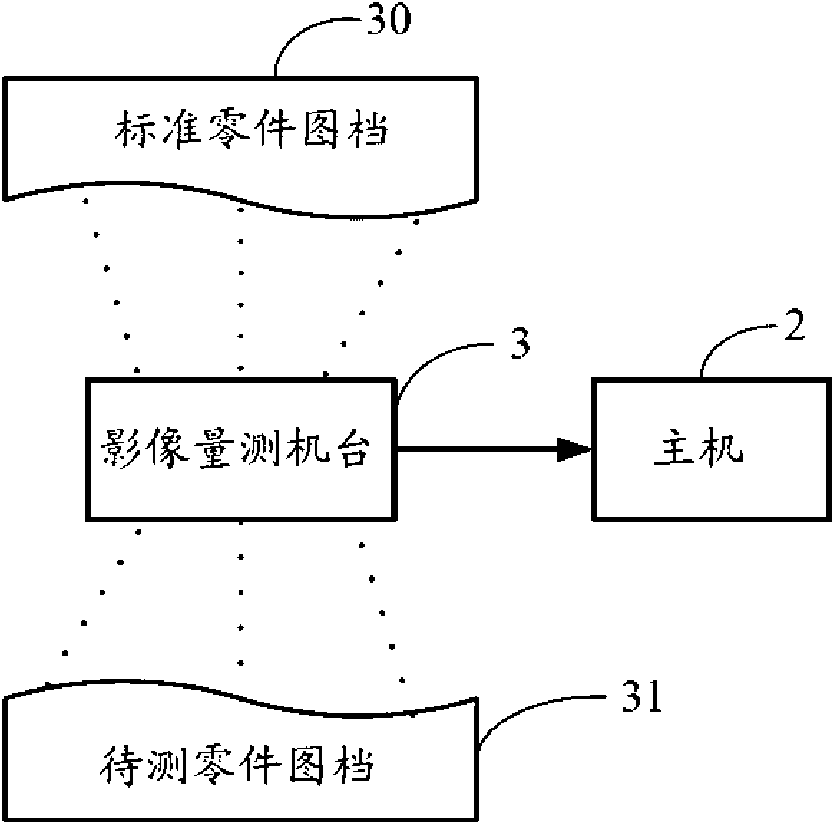

[0016] Wherein, the image measuring machine 3 is used to acquire the image files of the standard parts and the parts to be tested, and transmit the ingested image files to the test host 2, and the image files of the standard parts and the parts to be tested are composed of point clouds , the point cloud refers to a collection of points composed of multiple three-dimensional discrete points.

[0017] The storage body 20 may be a hard disk in the host 2, etc., for storing point cloud data 22. The point cloud data 22 includes point clouds of standard part drawings and point clouds of parts to be tested.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com