Test piece preparation mould special for shearing test and preparation method thereof

A shear test and test piece technology, which is applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of poor structure uniformity of the base layer and surface layer, affecting the accuracy of test results, loose and falling particles, etc., to achieve Satisfying integrity, moderate molding size, and satisfying the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

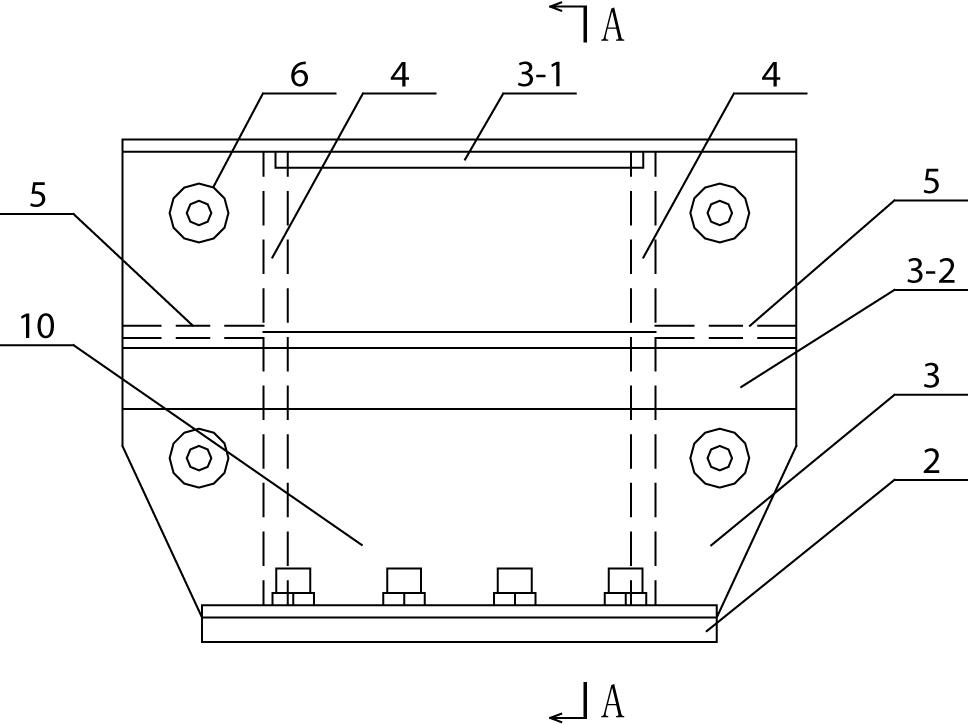

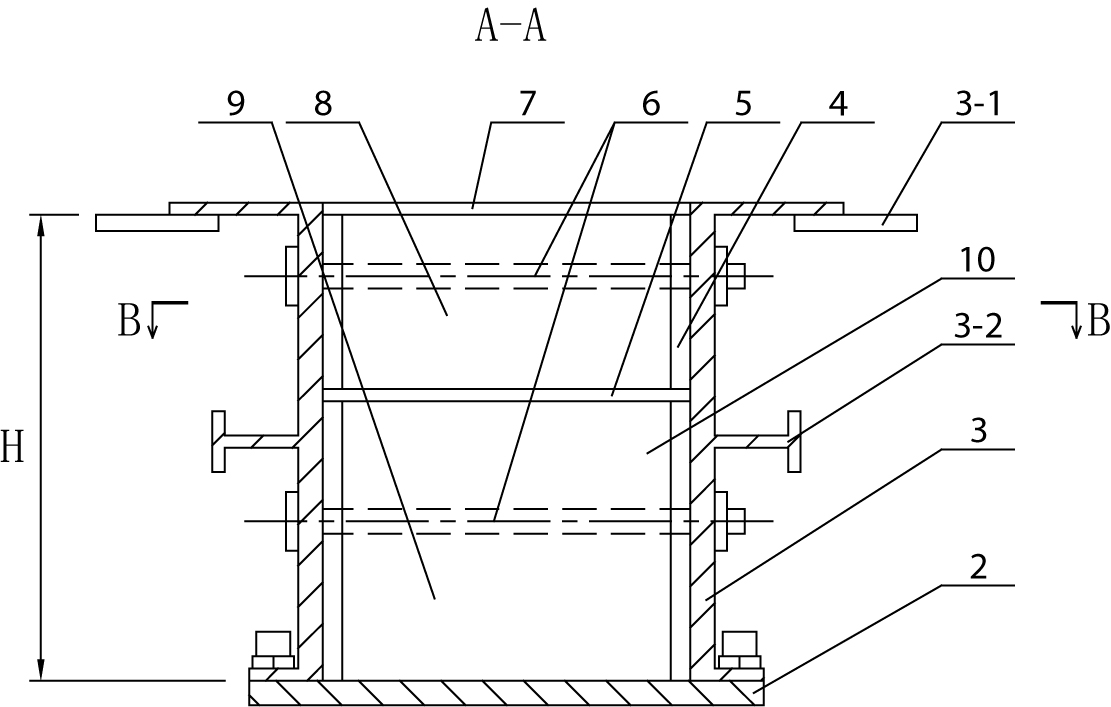

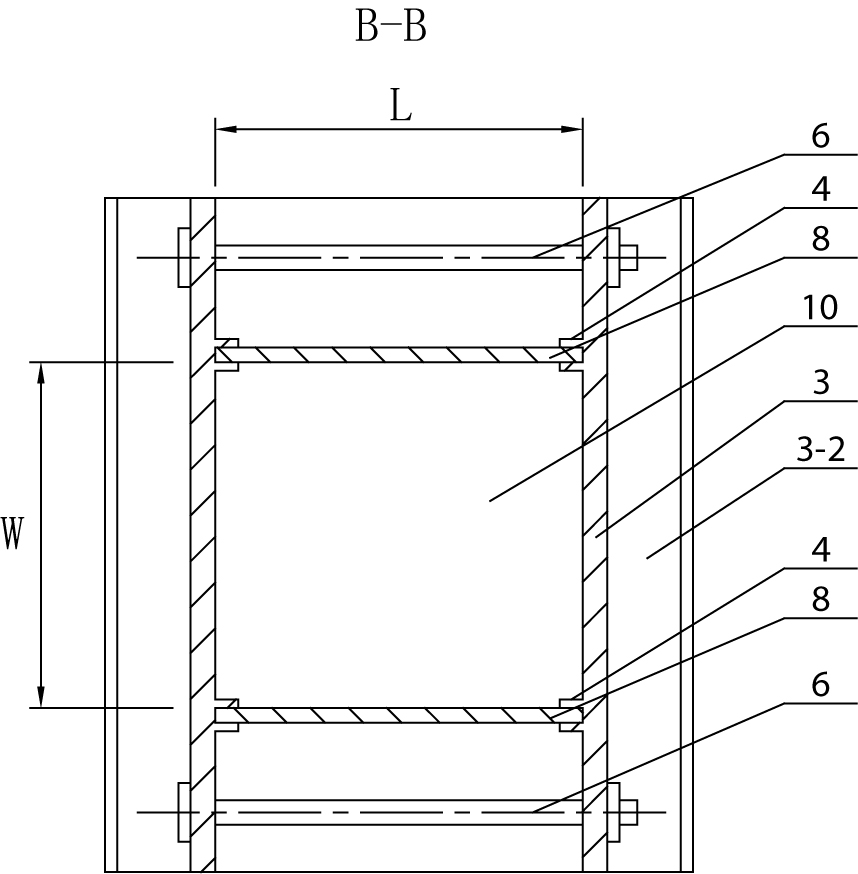

[0014] Specific implementation mode 1: Combination Figure 1 to Figure 4 The test piece preparation mold dedicated to the shear test of this embodiment is described, which includes a supporting base plate 2, two side plates 3, two first split pressure baffles 8 and two second split pressure baffles 9. The upper and lower ends of each side plate 3 are respectively provided with outer convex edges, the two side plates 3 arranged in parallel are vertically connected to the two ends of the supporting bottom plate 2, and the inner walls of the two side plates 3 are arranged oppositely Two pairs of vertical slots 4, two second split pressure baffles 9 are symmetrically arranged and inserted between the two side plates 3 through the slots 4, and the two first split pressure baffles 8 are respectively inserted Installed in the two pairs of slots 4 and located above the second split pressure baffle 9, the support bottom plate 2, two side plates 3, two first split pressure baffles 8 and t...

specific Embodiment approach 2

[0015] Specific implementation manner two: combination Figure 1 to Figure 3 The test piece preparation mold dedicated to the shear test of the present embodiment also includes at least four tie rods 6, which are horizontally and symmetrically arranged outside the two pairs of slots 4 of the two side plates 3 , The two side plates 3 are connected by a tie rod 6. The other components and connection relationships of this embodiment are the same as those of the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate the sample preparation mold dedicated to the shear test of this embodiment, the net size of the cavity 10 is length L×width W×height H=150mm×150mm×190mm, and the first split pressure baffle 8 The height H1 is 75 mm, and the height H2 of the second split pressure baffle 9 is 115 mm. The other components and connection relationships of this embodiment are the same as those of the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com