Square stackable glass lens module and manufacturing method thereof

A lens module and stacking technology, which is applied in the field of optical lenses, can solve the problems of limited use, difficulty in improving positioning accuracy, and high positioning accuracy requirements for aligning the central axis of the optical surface with the optical surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Square stacked lens module with columnar positioning mechanism

[0055] refer to Figure 9 , the present embodiment is a square stacked lens module 11, including two optical glass lenses 101 and 102, which are formed by cutting and separating an array of stacked lens modules 10 in a straight line. The square stacked lens module 11 cut from the middle part of the array stacked lens module 10 may not have the columnar positioning pins 1011 / 1021 and the number of positioning holes 1022 / 1012 of the positioning mechanism. The array optical glass lens module 100 includes two array optical glass lenses 101, 102 and four sets of positioning mechanisms (columnar positioning pins 1011 / 1021 and several columnar positioning holes 1022 / 1012), and the four sets of positioning mechanisms are respectively arranged on the first , at the four corners of the two-array optical glass lenses 101, 102, Figure 9 Only two groups of them are shown; after the first and second array optical gl...

Embodiment 2

[0056] Method for making a square stacked lens module with a positioning mechanism

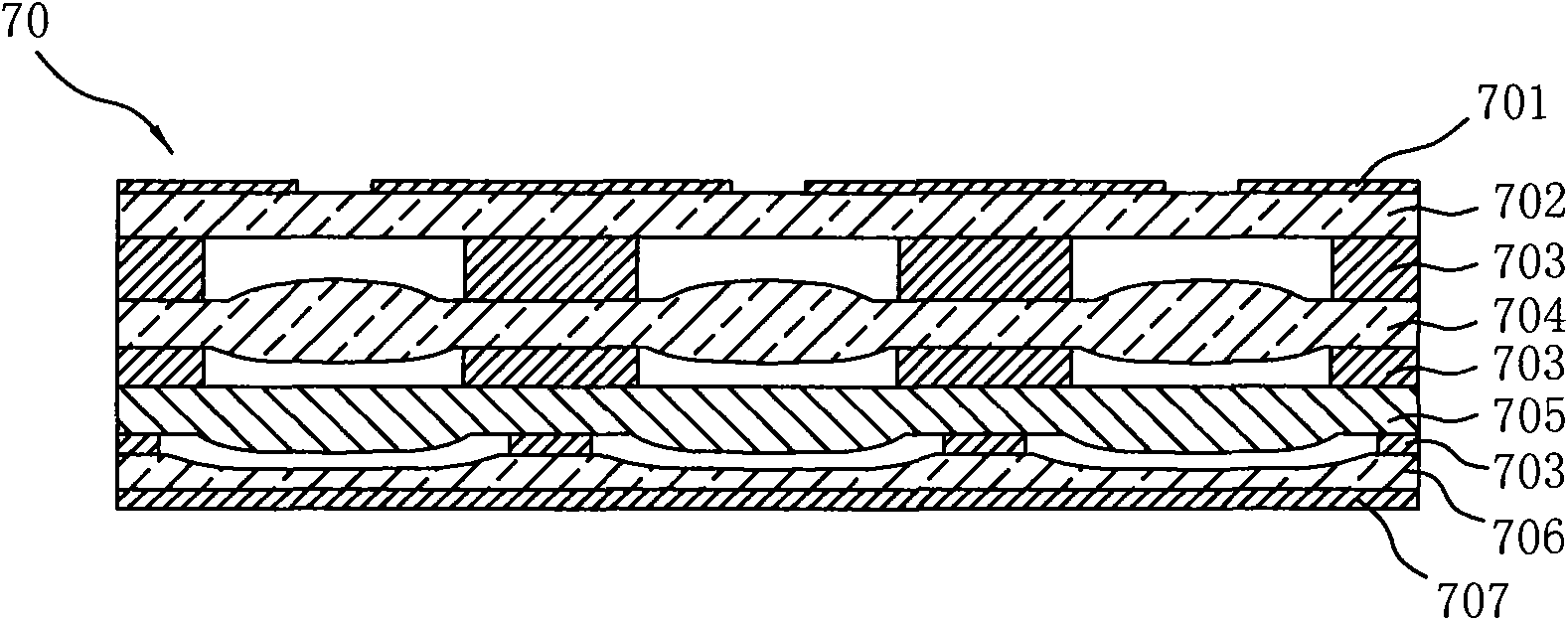

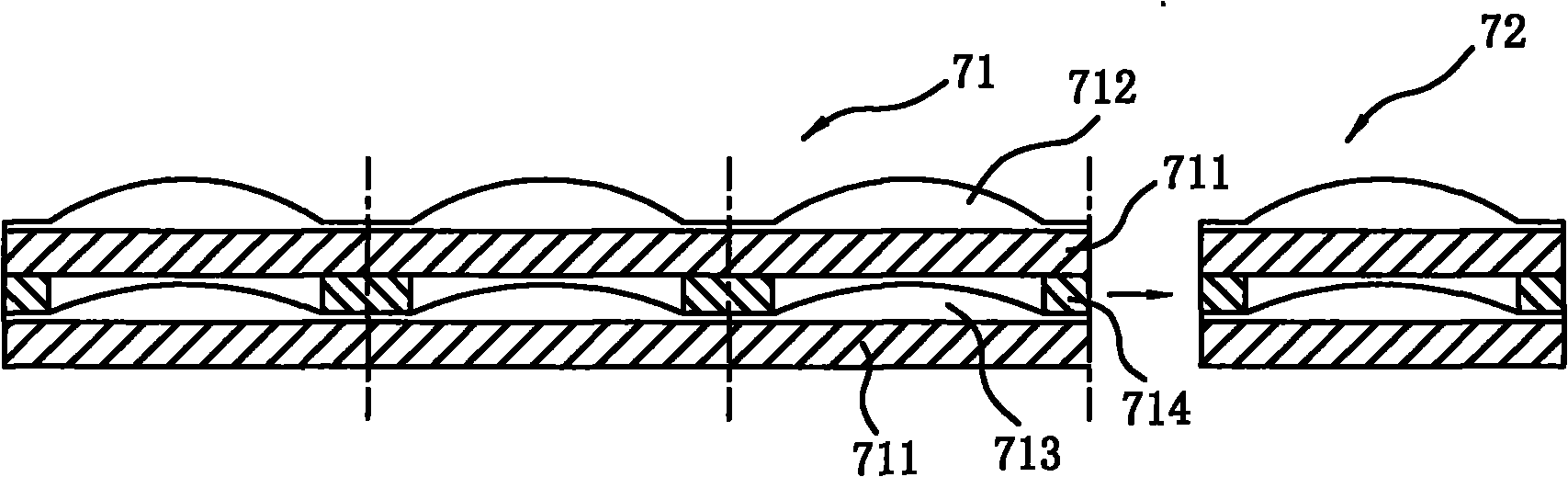

[0057] refer to Figure 4 The square stacked lens module 11 of this embodiment is formed by cutting and separating an arrayed stacked lens module 10 in a straight line. The arrayed stacked lens module 10 of this embodiment includes two arrays of optical glass lenses 101, 102, and four sets of positioning mechanisms , a circuit board (the first optical element) 105, several image sensing elements (the second optical element) 106, several spacers (the third optical element) 107, and are made up of bonding glue 104; The positioning mechanism is in Figure 4 Only one group of them is shown in the figure; wherein, the number of the image sensing element 106 relative to the optical active area (optical surface) of the array can be preset on the circuit board 105; when the circuit board 105 is separated from the second array optical glass Lens 102 is positioned, and after the first array optical gl...

Embodiment 3

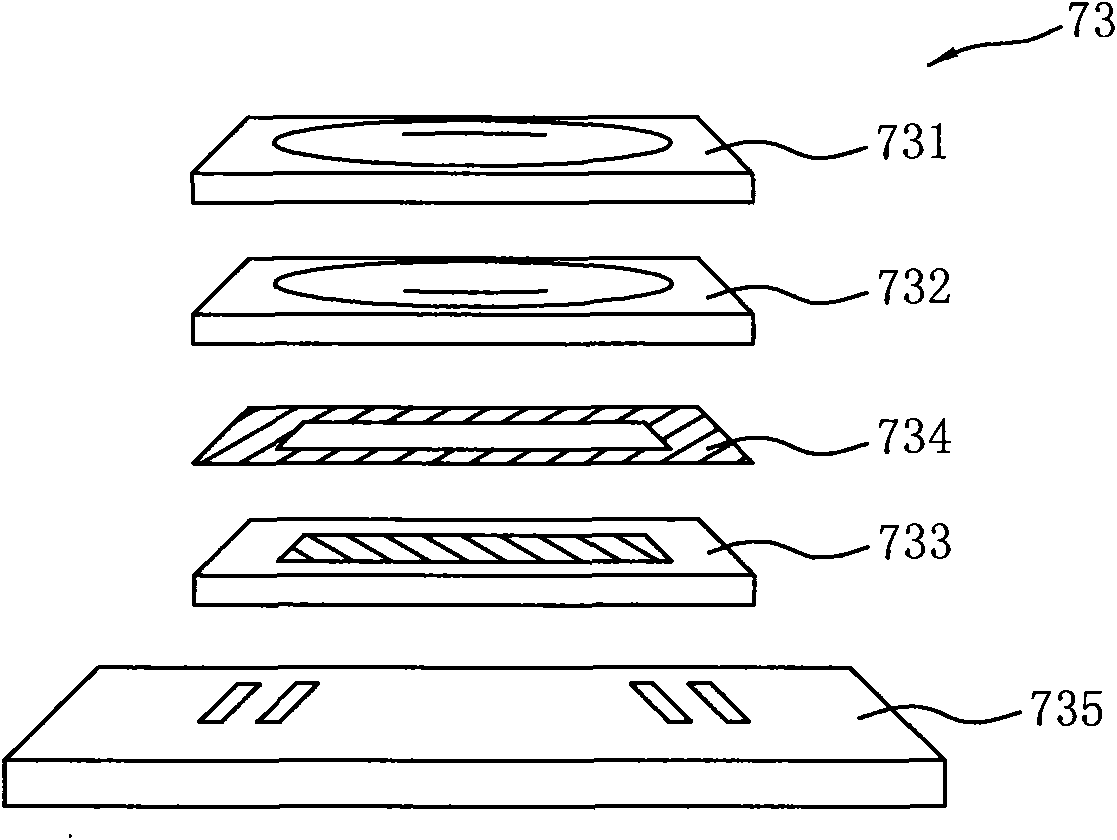

[0069] Square stacked lens module with through hole as positioning mechanism

[0070] refer to Figure 7 , 8 The square stacked lens module 11 of this embodiment is formed by cutting and separating an array stacked lens module 10 in a straight line. The array stacked lens module 10 includes two arrays of optical glass lenses 101, 102 (ie, the first and second array optical glass lens), four sets of positioning mechanisms, a circuit board (ie, the first optical element) 105, several image sensing elements (ie, the second optical element) 106, and several spacers (ie, the third optical element) 107; Wherein, the positioning mechanism is four groups of through holes 108, in Figure 7 Only two groups of through holes 108 are shown in the figure; the number of image sensing elements 106 relative to the optical active area (optical surface) can be preset on the circuit board 105; the circuit board 105 is positioned with the second array of optical glass lenses 102 at a predetermi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com