Method for optimizing beer production formula

An optimization method and production formula technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficulties and lack of global optimal search robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

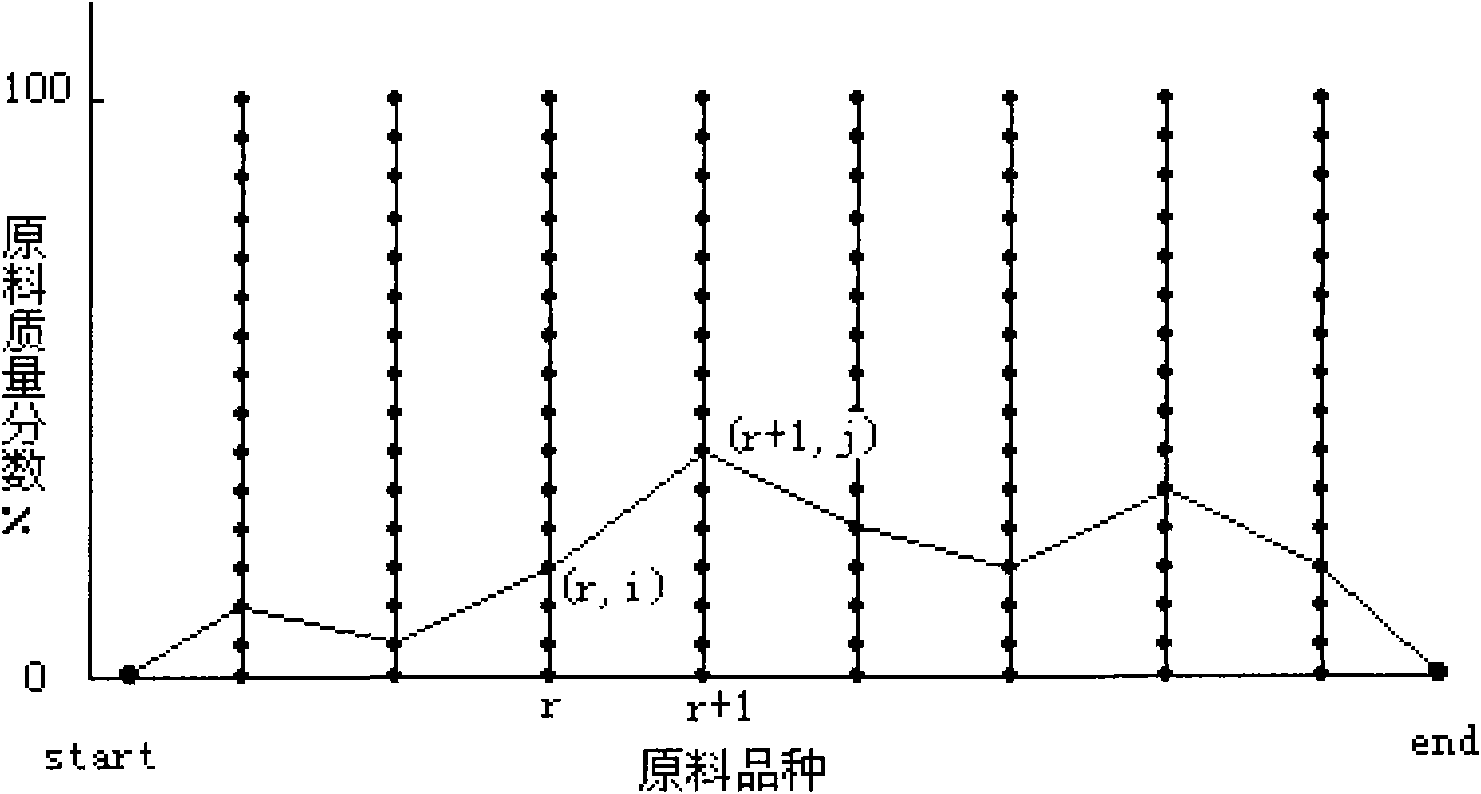

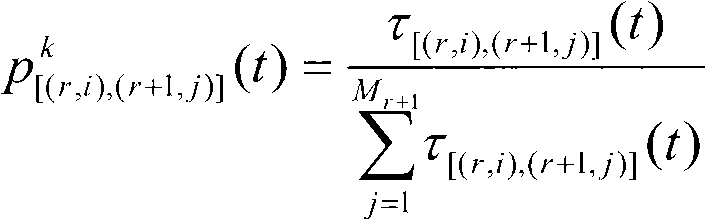

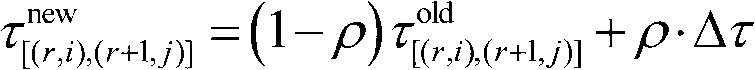

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

[0047] The inventive method comprises the following steps:

[0048]Step 1. Obtain parameters such as tank production rate, α-amino nitrogen, saccharification power, total soluble nitrogen, β-glucan, and unit price of the main raw materials (including barley malt, special malt, wheat malt, and auxiliary raw materials) in the beer formula. The data can be obtained through the supplier, or through statistics during the production process;

[0049] Step 2. Establish a comprehensive production performance index estimation model based on raw material parameters. The main comprehensive performance indexes considered are maltosaccharification power, wort total nitrogen, wort α-amino nitrogen, wort β-glucan, and lauter tank dross layer thickness.

[0050] ① Maltosaccharification power

[0051] Under normal saccharification operation (saccharification at 65-68°C for 30-45 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com