Novel molten salt temperature switch and preparation method thereof

A technology of temperature switch and molten salt, which is applied in the direction of thermal switch components, etc., can solve the problems of unusable and uneconomical use of temperature switches, and achieve the effects of long service life, small size and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

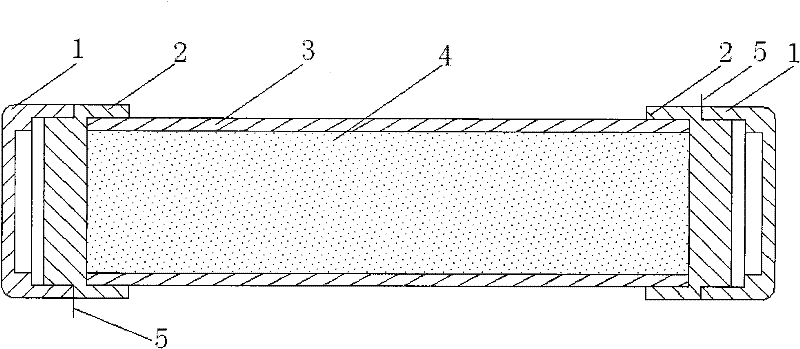

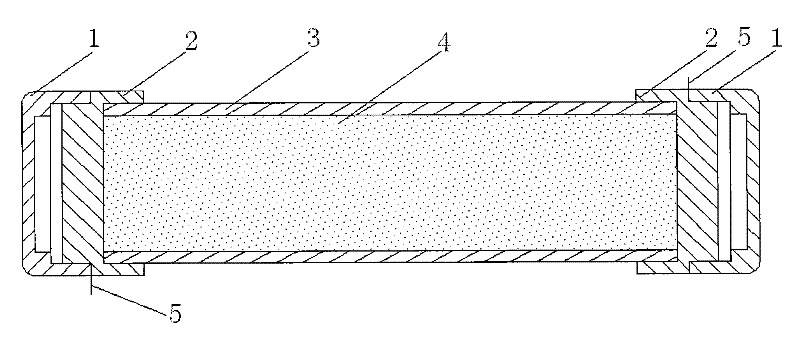

[0027] The materials selected for making the new molten salt temperature switch in this embodiment are as follows:

[0028] The inner diameter of the stainless steel nut (1) is 11mm, the outer diameter is 14.5mm, and the length is 8.5mm, the length of the external thread is greater than 5mm, and the length of the internal thread is greater than 5mm; The inner diameter is 12mm, the outer diameter is 14.5mm, the length is 13mm, the length of the outer thread is greater than 5mm, and the length of the inner thread is greater than 5mm; the insulating tube (3) is a corundum insulating sleeve with an inner diameter of 7mm, an outer diameter of 12mm, and a length of 20mm , the length of the external thread is greater than 5mm, the molten salt (4) selects KSCN-NaCl, and its KSCN and NaCl are analytically pure; the conductive wire (5) selects a copper wire, and the preparation process is as follows:

[0029] Step 1: Dry the stainless steel nut, copper guide piece, and corundum sleeve f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com