Slide-way structure

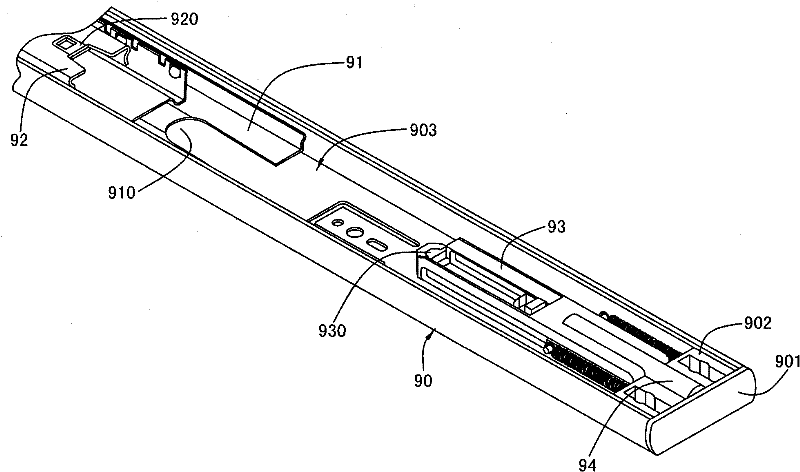

A slide rail and inner slide rail technology, which is applied to furniture parts, home appliances, drawers, etc., can solve the problems of limited length of the inner slide rail 92, limited length of the full extension, and impracticality, so as to reduce the manufacturing cost and increase the full extension. Proportion, simplifying the troublesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

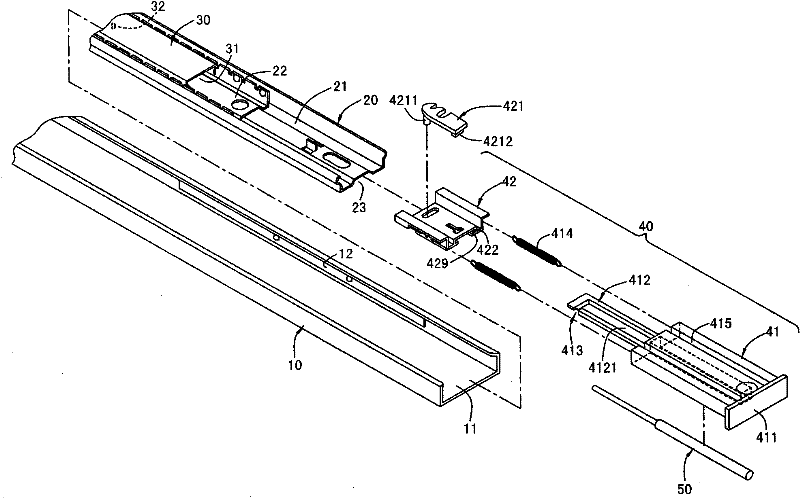

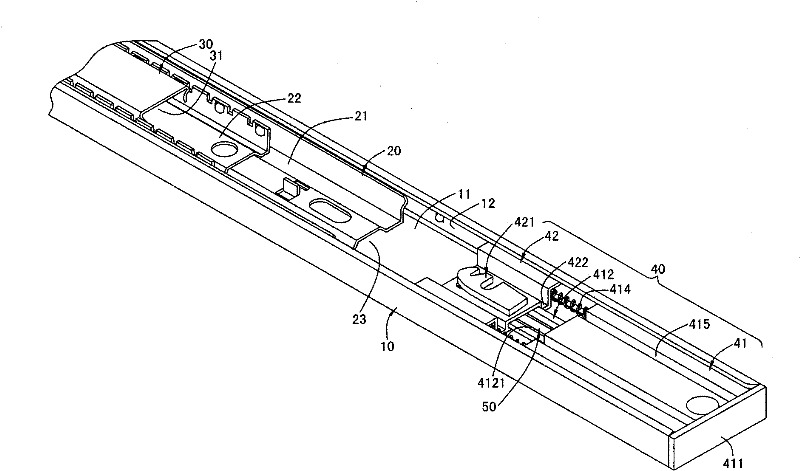

[0056] see figure 2 and image 3 As shown, it is a schematic diagram of decomposition and assembly of the first embodiment disclosed in the present invention. The slide rail structure disclosed in the first embodiment of the present invention includes an outer slide rail 10 , a middle slide rail 20 , an inner slide rail 30 , a reset unit 40 and a buffer member 50 . Some of the structural components and actuation methods belong to the prior art, and are not the subject of protection in this case, so the actuation principles of these components will not be described in detail, but it is not limited to this, and it is described in advance here.

[0057] The outer slide rail 10 is roughly a concave elongated structure, which has an outer rail space 11 inside, and a ball group 12 is arranged in the outer rail space 11, and the outer rail space 11 can be used for the middle slide rail 20 and the inner slide rail. 30 is assembled with the reset unit 40 , and the middle slide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com