Closure mechanism of a hollow fiber module and hollow fiber module

A hollow fiber technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of reduced separation performance of hollow fiber membranes, partial drying of hollow fiber membranes, and reduced airtightness, so as to maintain separation performance , Improve the effect of sterility and high airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

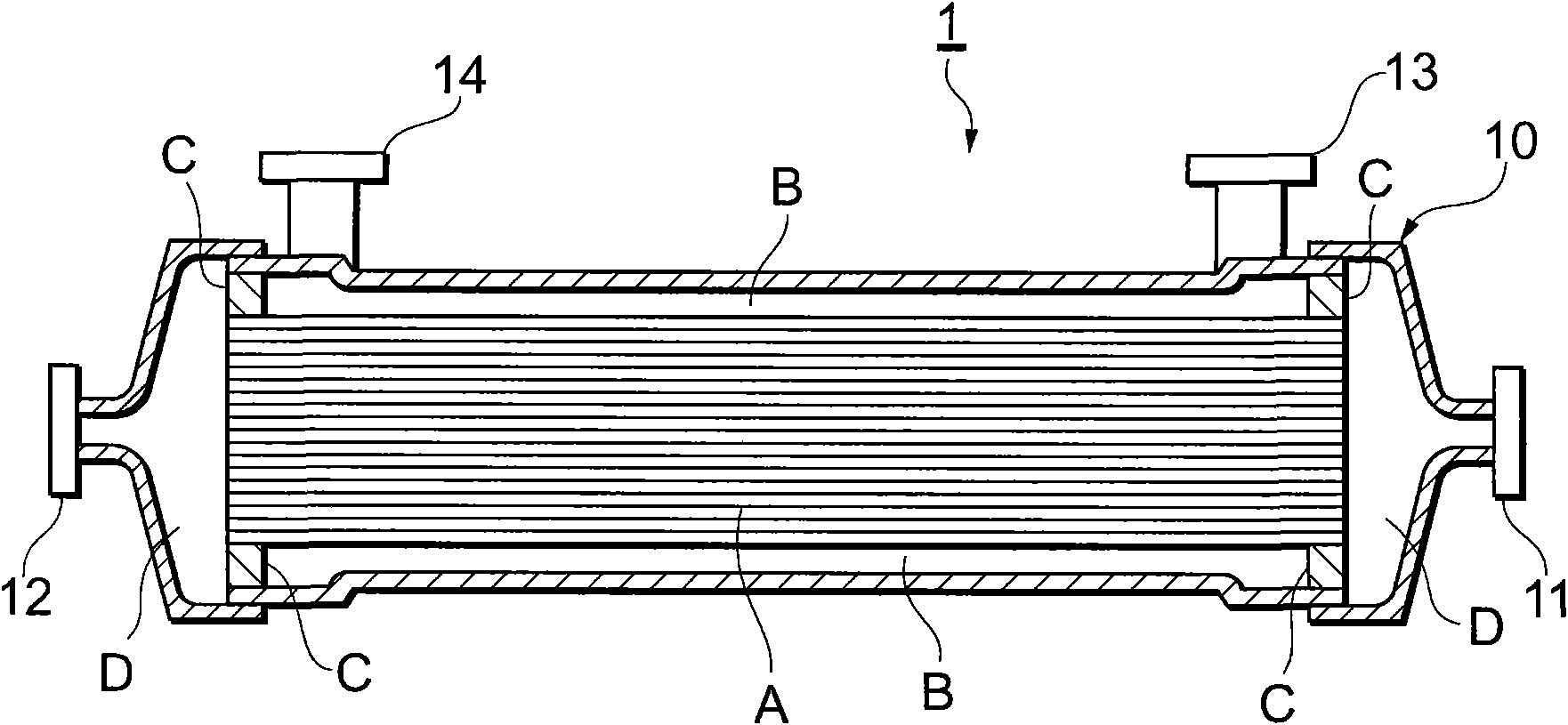

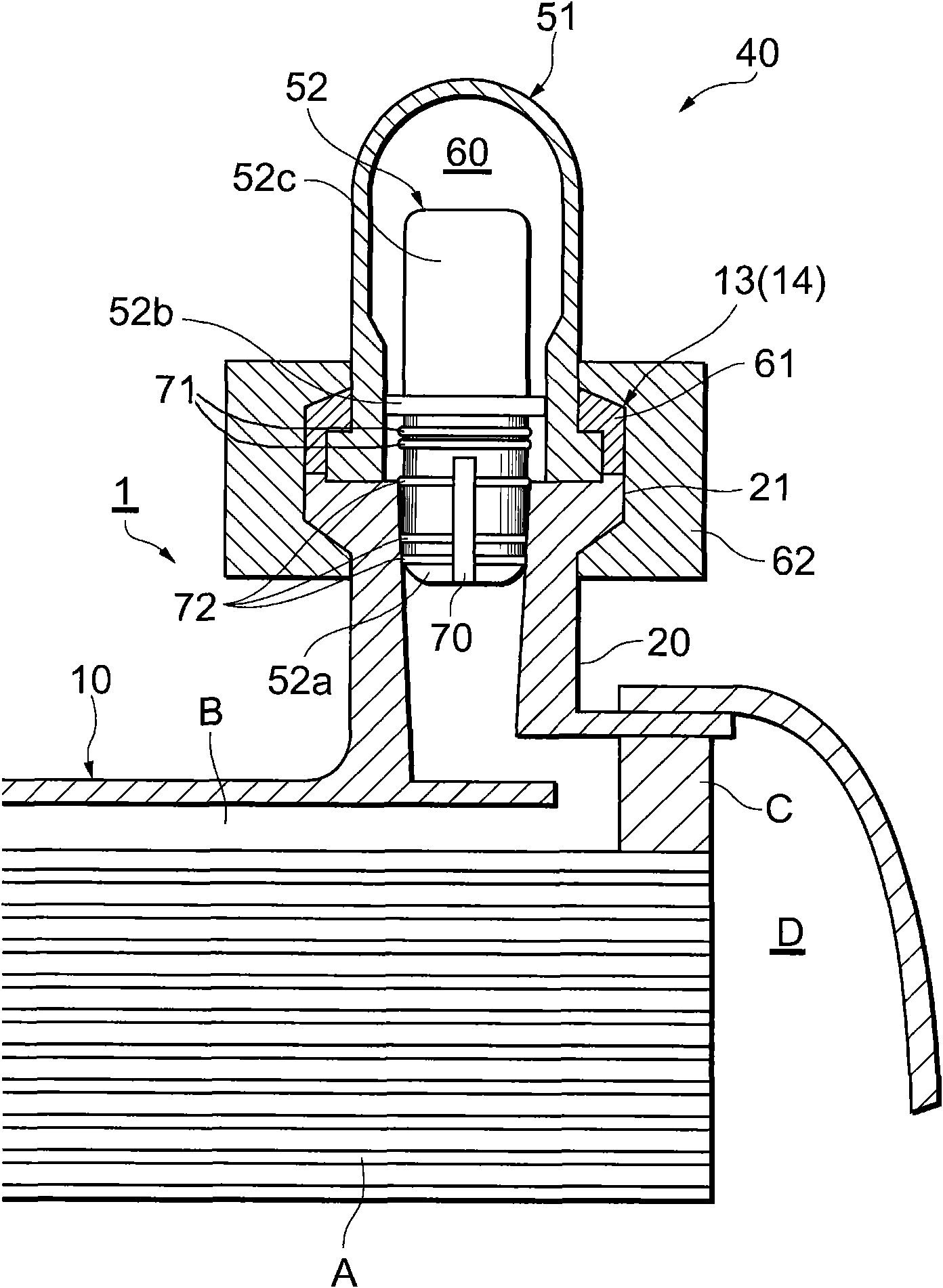

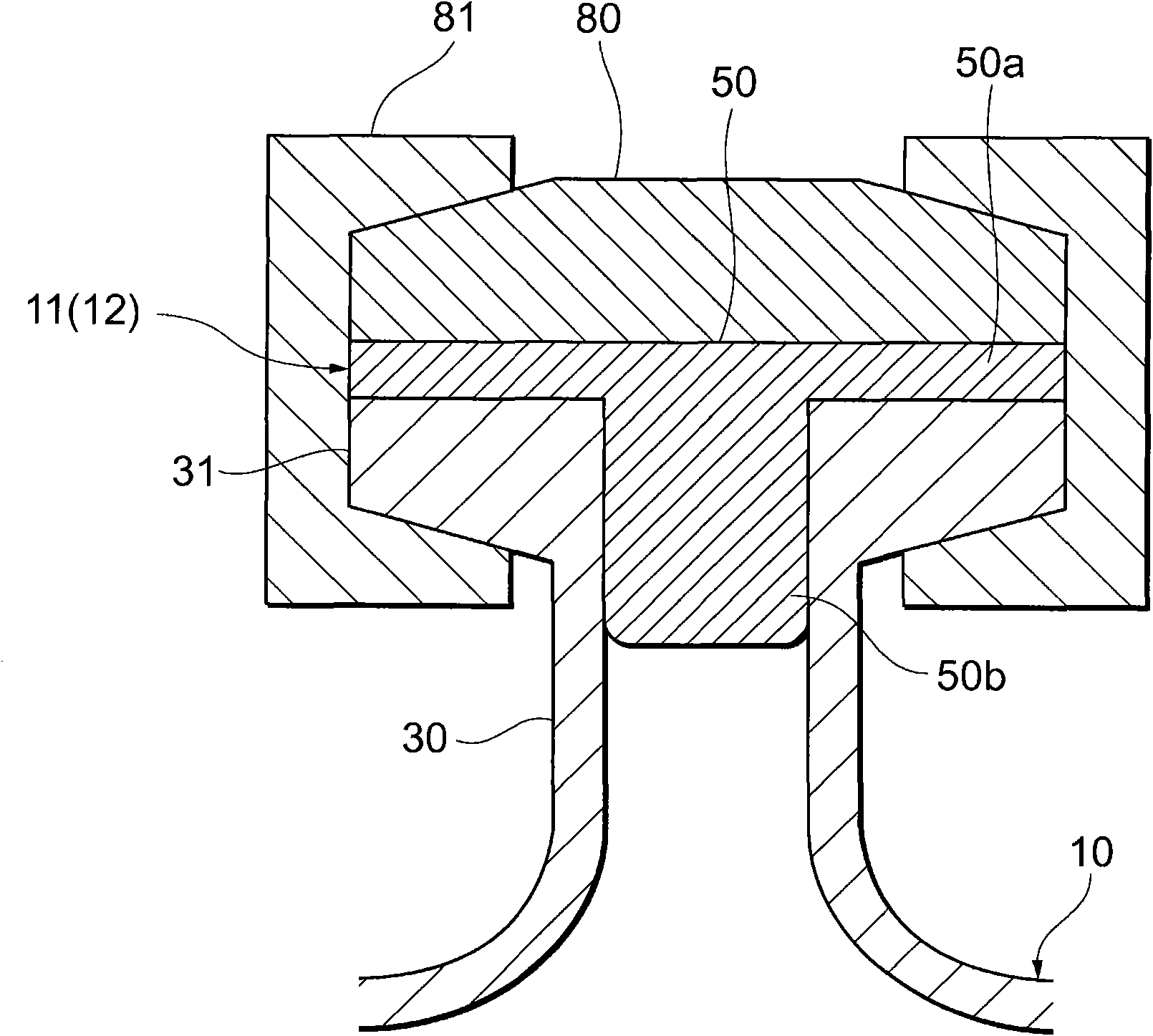

[0033] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 It is a cross-sectional view schematically showing the configuration of the hollow fiber module 1 to which the sealing mechanism of the present embodiment is applied.

[0034] For example, if figure 1 As shown, the hollow fiber module 1 includes: a hollow fiber membrane bundle A is accommodated along the length direction, and a cylindrical casing 10 with both ends closed; Two primary liquid-passing nozzles 11 and 12 connected internally; two secondary liquid-passing nozzles 13 and 14 formed on the outer peripheral side of the casing 10 and communicating with the outer peripheral space B of the hollow fiber membrane bundle A in the casing 10 .

[0035]Both ends of the hollow fiber membrane bundle A are fixed to the inner wall surface of the casing 10 by the sealing agent C. With the encapsulant C, the housing 10 is formed with an outer peripheral spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com