Oil separator

An oil separator and oil separation technology, applied in separation methods, filtration separation, membrane filters, etc., can solve problems such as distance deviation, thickness deviation of non-woven fabrics, and influence of oil separation performance, and achieve reduced pressure loss, high oil The effect of separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

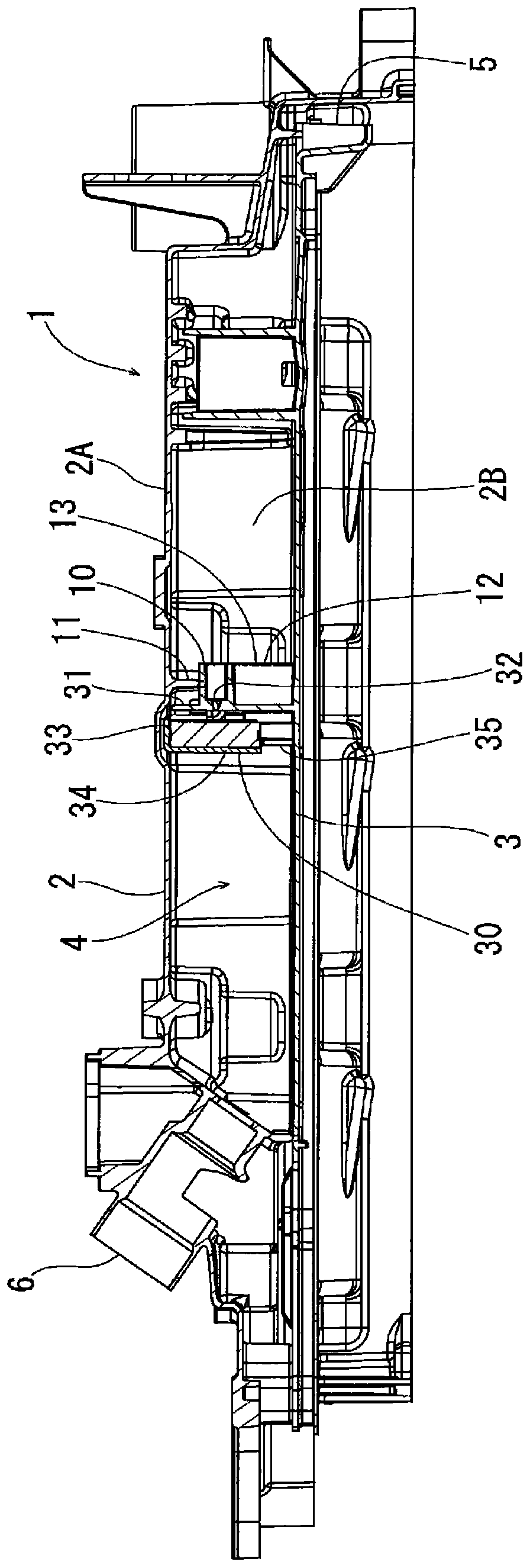

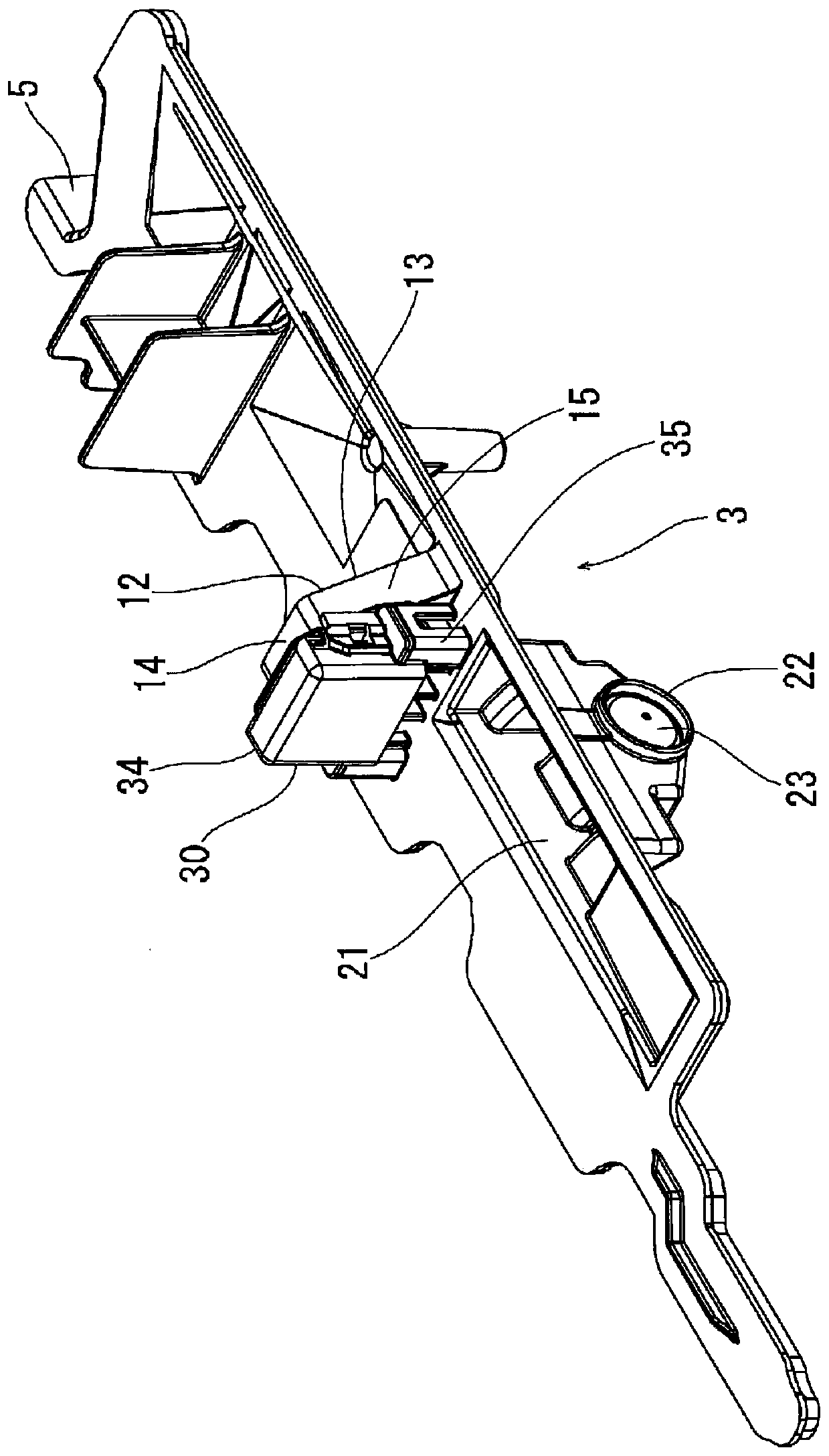

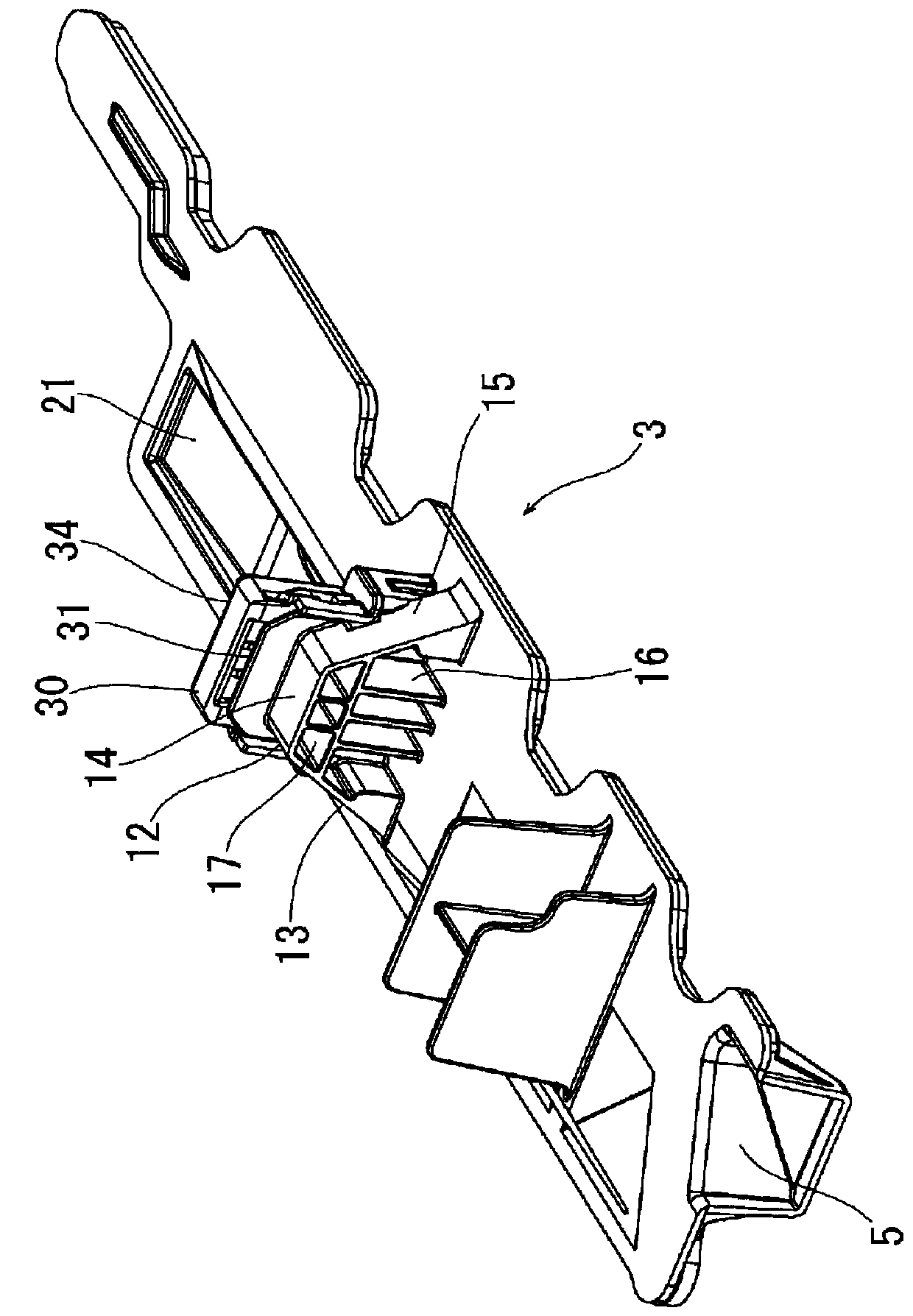

[0026] Embodiments of the present invention will be described below based on the drawings.

[0027] figure 1 The overall structure of the blow-by gas line 1 to which the oil separator 30 according to the embodiment of the present invention is installed is shown in . As shown in the figure, the blow-by gas line 1 is constituted by combining an upper member 2 and a lower member 3, and a fluid passage 4 is formed in a region surrounded by the two members. Blow-by gas (gas leaked from the combustion chamber of the engine) is introduced from the opening end 5 provided on the upstream side of the lower member 3 , and passes through the fluid passage 4 from the opening end 6 provided on the downstream side of the upper member 2 . discharge. In addition, the upper member 2 is a member integrated with the cylinder head cover of the engine, and has a top wall 2A and side walls 2B on both sides.

[0028] A partition wall 10 partitioning the fluid passage 4 into an upstream side and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com