A kind of preparation method of anti-shrinkage polytetrafluoroethylene composite nanofiltration membrane

A polytetrafluoroethylene, composite nanofiltration membrane technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of separation layer breakage and composite nanofiltration membrane separation performance degradation, to prevent breakage, The effect of improving water flux and good shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

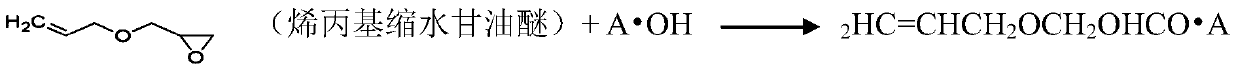

Method used

Image

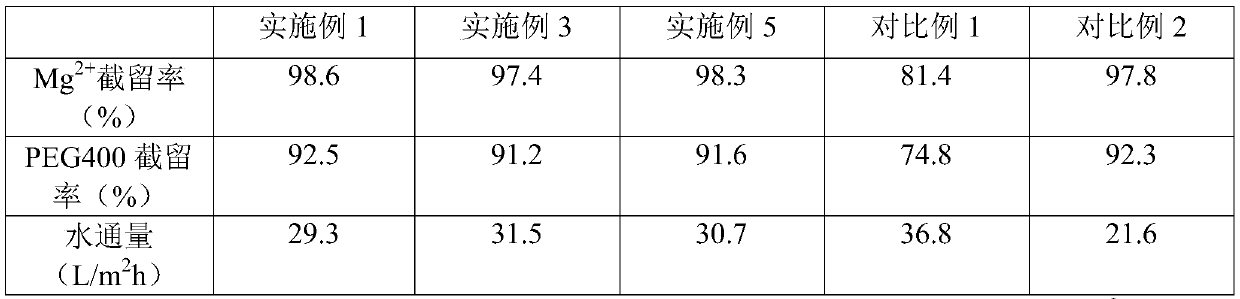

Examples

Embodiment 1

[0032] The preparation method of hydrophilic polytetrafluoroethylene microporous base membrane comprises the following steps:

[0033] The polytetrafluoroethylene microporous base membrane is subjected to plasma treatment under a nitrogen atmosphere, and then the plasma treated polytetrafluoroethylene microporous base membrane is immersed in the ethanol aqueous solution of the modified Polygonatum polysaccharide extract, and the modified Polygonatum polysaccharide is extracted The mass concentration of the substance is 5%, the mass fraction of the ethanol aqueous solution is 65%, and then the initiator azobisisobutyronitrile is added, and the mass concentration percentage of the initiator azobisisobutyronitrile in the ethanol aqueous solution is 0.3%, at 63 ℃ After reacting for 4 hours, the polytetrafluoroethylene microporous base membrane was taken out, washed with deionized water to remove unreacted monomers, and dried to obtain a hydrophilic polytetrafluoroethylene microporo...

Embodiment 2

[0044] The preparation method of hydrophilic polytetrafluoroethylene microporous base membrane comprises the following steps:

[0045] The polytetrafluoroethylene microporous base membrane is subjected to plasma treatment under a nitrogen atmosphere, and then the plasma treated polytetrafluoroethylene microporous base membrane is immersed in the ethanol aqueous solution of the modified Polygonatum polysaccharide extract, and the modified Polygonatum polysaccharide is extracted The mass concentration of the substance is 3%, the mass fraction of the aqueous ethanol solution is 65%, and then the initiator azobisisobutyronitrile is added, and the mass concentration percentage of the initiator azobisisobutyronitrile in the aqueous ethanol solution is 0.3%. After reacting for 4 hours, the polytetrafluoroethylene microporous base membrane was taken out, washed with deionized water to remove unreacted monomers, and dried to obtain a hydrophilic polytetrafluoroethylene microporous base ...

Embodiment 3

[0056] The preparation method of hydrophilic polytetrafluoroethylene microporous base membrane comprises the following steps:

[0057] The polytetrafluoroethylene microporous base membrane is subjected to plasma treatment under a nitrogen atmosphere, and then the plasma treated polytetrafluoroethylene microporous base membrane is immersed in the ethanol aqueous solution of the modified Polygonatum polysaccharide extract, and the modified Polygonatum polysaccharide is extracted The mass concentration of the substance is 8%, the mass fraction of the aqueous ethanol solution is 65%, and then the initiator azobisisobutyronitrile is added, and the mass concentration percentage of the initiator azobisisobutyronitrile in the aqueous ethanol solution is 0.4%. After reacting for 4 hours, the polytetrafluoroethylene microporous base membrane was taken out, washed with deionized water to remove unreacted monomers, and dried to obtain a hydrophilic polytetrafluoroethylene microporous base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com