Bonded body, separation membrane module equipped with same, and method for producing alcohol

A bonding method and manufacturing method technology, applied in the field of bonding body, can solve the problems of many restrictions on energy equipment, reduced reaction speed, and large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

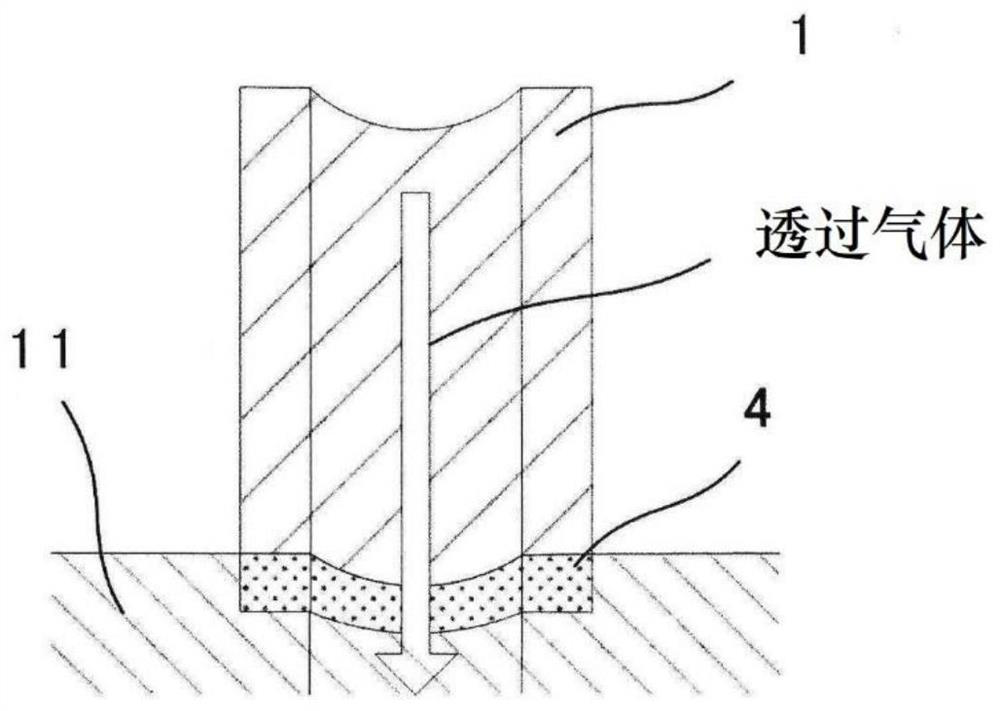

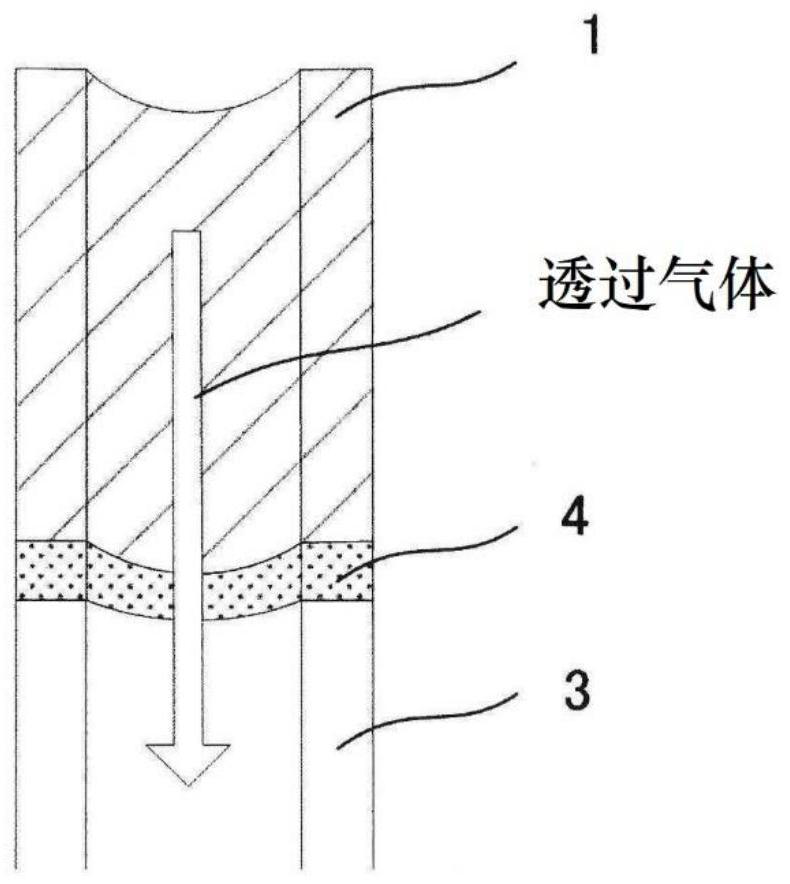

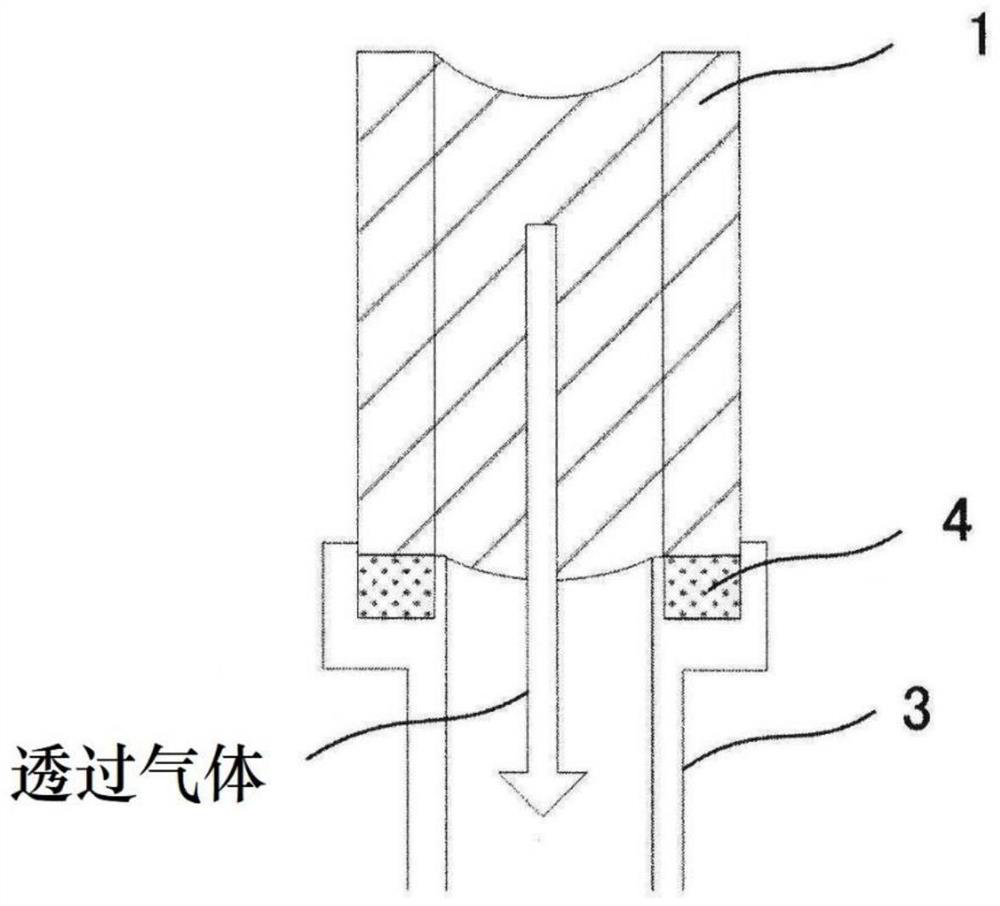

[0130] A first embodiment of the present invention is a bonded body in which a composite of zeolite and an inorganic porous support and a dense member are bonded through lead-free inorganic glass, wherein the thermal expansion of the lead-free inorganic glass is The factor is 30×10 -7 / K above and 90×10 -7 / K or less, and the softening point is 550°C or less.

[0131]

[0132] In this embodiment, lead-free inorganic glass means that the content of lead (Pb) in terms of PbO is 10% by mass or less, preferably 5% by mass or less, more preferably 3% by mass or less, further preferably 2% by mass or less, especially It is preferably 1% by mass or less, most preferably 0% by mass of inorganic glass.

[0133] The thermal expansion coefficient of the lead-free inorganic glass involved in this embodiment is usually 30×10 -7 / K or more, preferably 40×10 -7 / K or more, more preferably 45×10 -7 / K above, in addition, usually 90×10 -7 / K or less, preferably 80×10 -7 / K or less, mo...

no. 2 approach

[0188] A second embodiment of the present invention is a bonded body obtained by bonding a composite of zeolite and an inorganic porous support and a dense member through inorganic glass, wherein the dense member is a metal member, and the inorganic The coefficient of thermal expansion of glass is 30×10 -7 / K above and 90×10 -7 / K or less, and the softening point is 550°C or less.

[0189]

[0190] The thermal expansion coefficient of the inorganic glass involved in this embodiment is usually 30×10 -7 / K or more, preferably 40×10 -7 / K or more, more preferably 45×10 -7 / K above, in addition, usually 90×10 -7 / K or less, preferably 80×10 -7 / K or less, more preferably 75×10 -7 / K below.

[0191] In this embodiment, the thermal expansion coefficient of the inorganic glass is usually 60% or more, preferably 70% or more, more preferably 80% or more, and usually 200% or less, preferably 150% or less, and more Preferably it is 120% or less. When the thermal expansion coef...

no. 3 approach

[0234] The third embodiment of the present invention is a bonded body formed by bonding a composite of zeolite and an inorganic porous support and a dense member with an inorganic binder, and the thermal expansion coefficient of the inorganic binder after curing is 30×10 -7 / K~90×10 -7 / K.

[0235]

[0236] The inorganic binder used in this embodiment is characterized in that its main component is an inorganic substance, preferably an oxide or a nitride, so even when it is used under high temperature and pressure and further in contact with an organic solvent or an organic gas High airtightness can be maintained even under low conditions, and the durability is excellent.

[0237] In addition, the inorganic binder in the present embodiment is a substance that is bonded by curing through a chemical reaction and does not return to its original state even when heated. Inorganic binders are preferable since they can usually be bonded at 200° C. or lower and thus hardly damage t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com