Automatic cutting machine for frame strip

A cutting machine and frame bar technology, which is applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problem of cutting corners that cannot be cut out of other angles, and achieve reduced work load, high processing accuracy, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

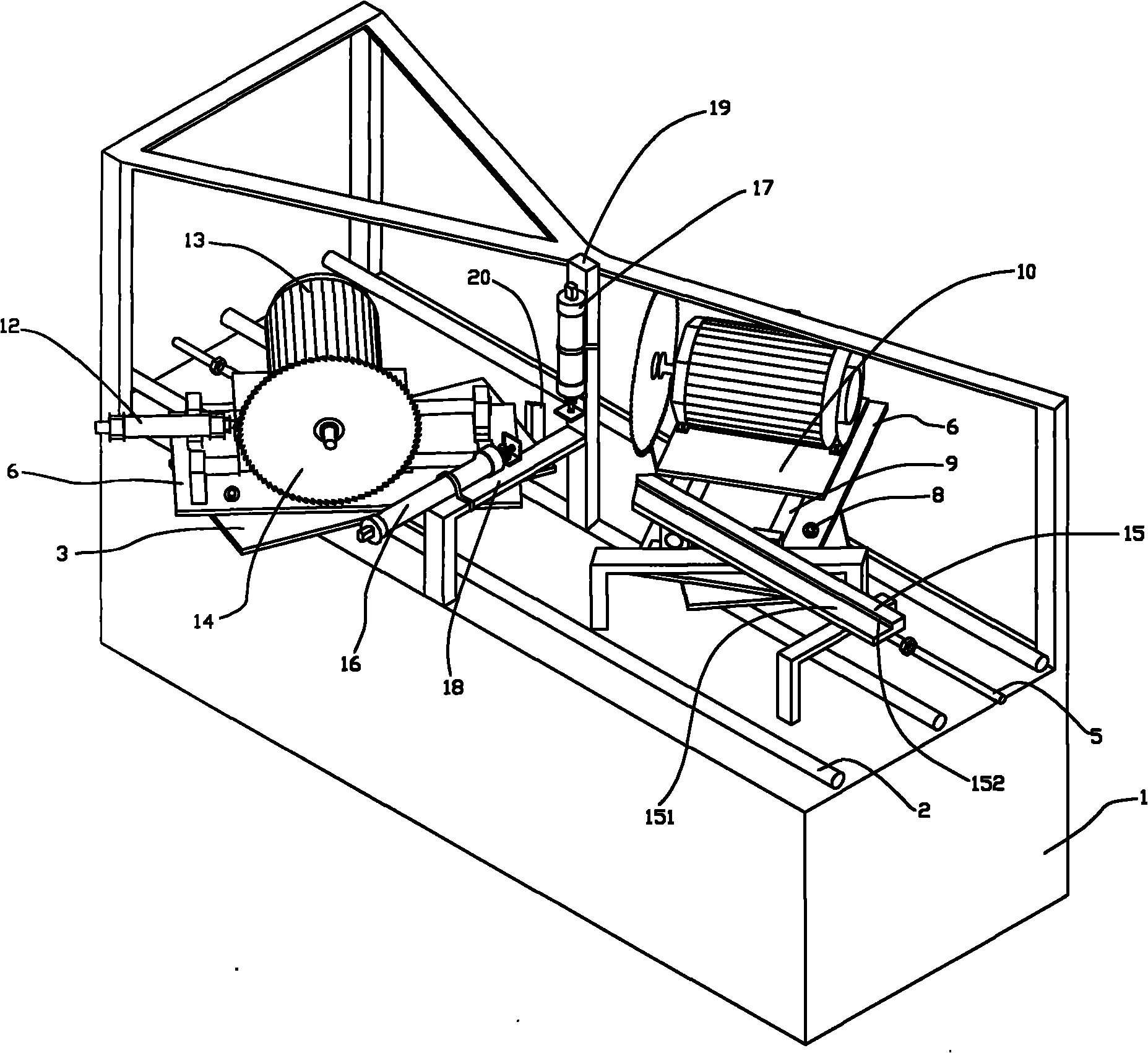

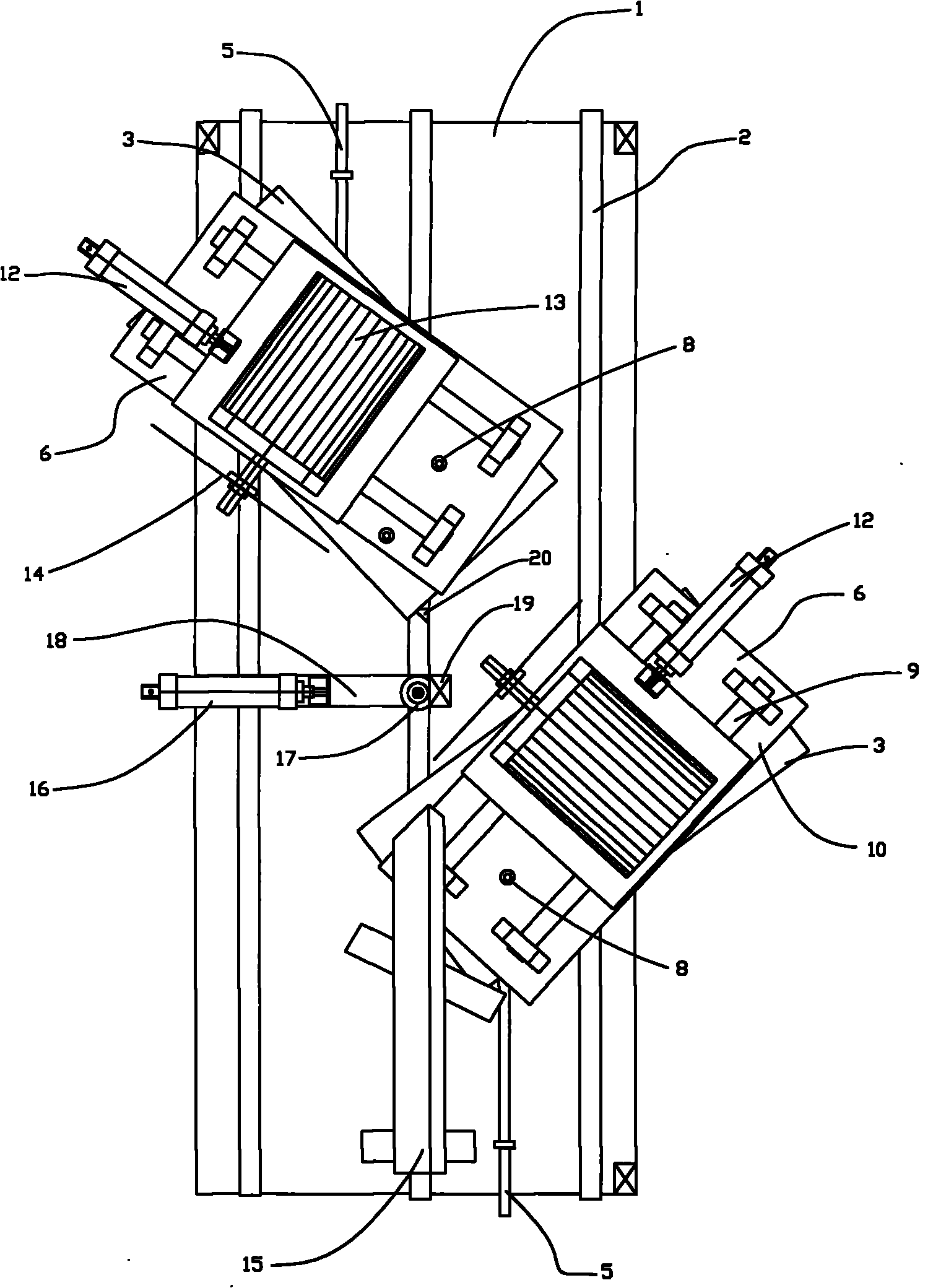

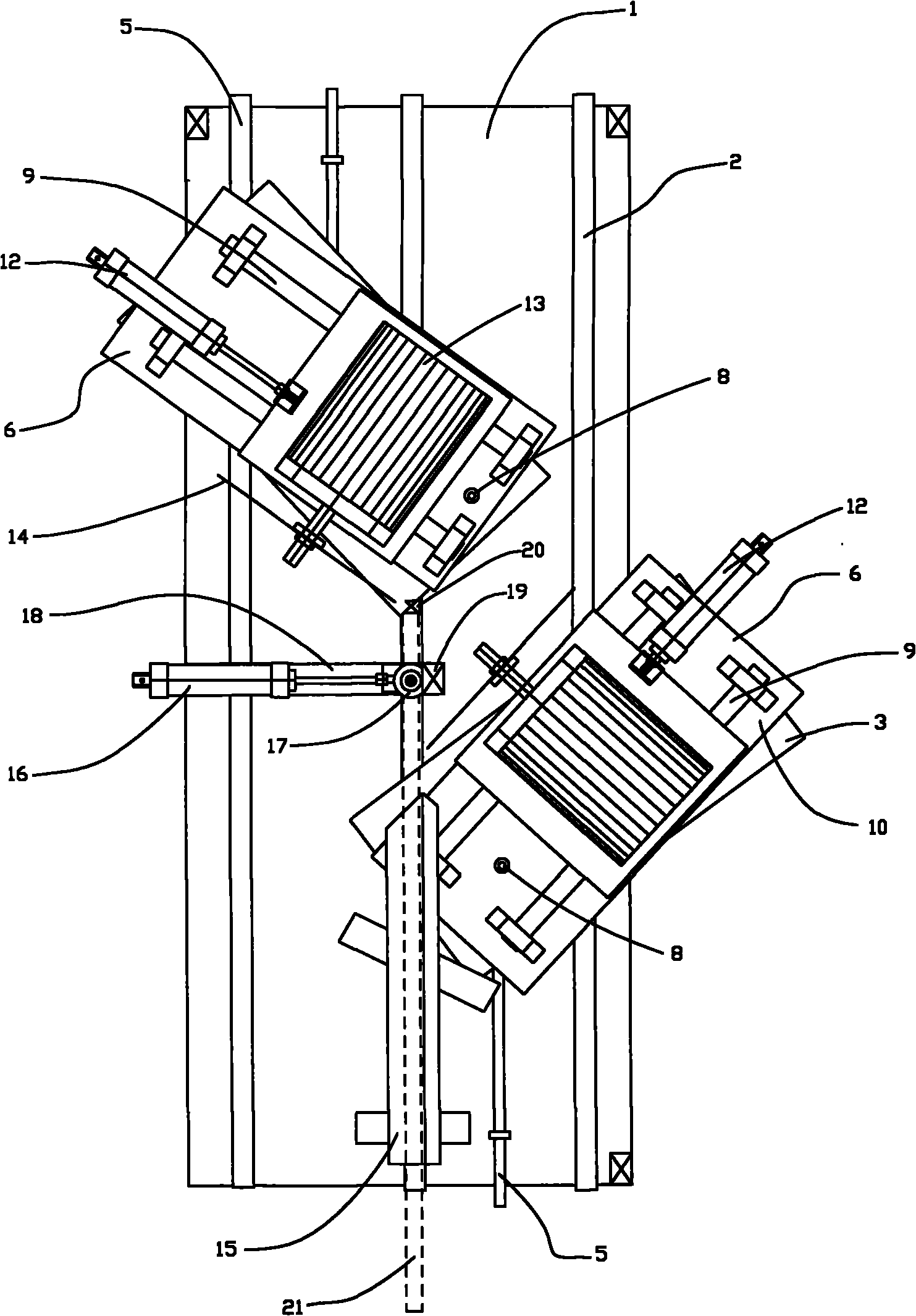

[0025] Example 1: see figure 1 , figure 2 , Figure 4 , an automatic frame cutting machine, comprising a machine body 1, three long slide rails 2 arranged in parallel are erected on the top surface of the machine tool body 1, and a pair of long slide rails that can move relatively along the long slide rails are arranged on the long slide rails 2. Sliding platform 3, two sliding platforms 3 are arranged on both sides of the middle long slide rail 2. The lower surface of the sliding platform 3 is fixedly connected with two slide rail sleeves 4, the aperture of the slide rail sleeve 4 matches the outer diameter of the long slide rail 2 and is socketed on the long slide rail 2, and the slide platform 3 slides through the slide rails. The sleeve is connected with the long slide rail 2 and can move relatively along the long slide rail. The sliding platform 3 is also provided with an adjusting screw 5 for controlling the sliding of the sliding platform on the long slide rail and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com