Steering drive device for automobile headlight

A technology of steering transmission and transmission device, which is applied in signal devices, vehicle parts, transportation and packaging, etc. It can solve the problems of not very compact structure of gear transmission mechanism, not very stable transmission process, insufficient rotational torque, etc., and achieve compact structure , high assembly efficiency, and the effect of lightweight production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

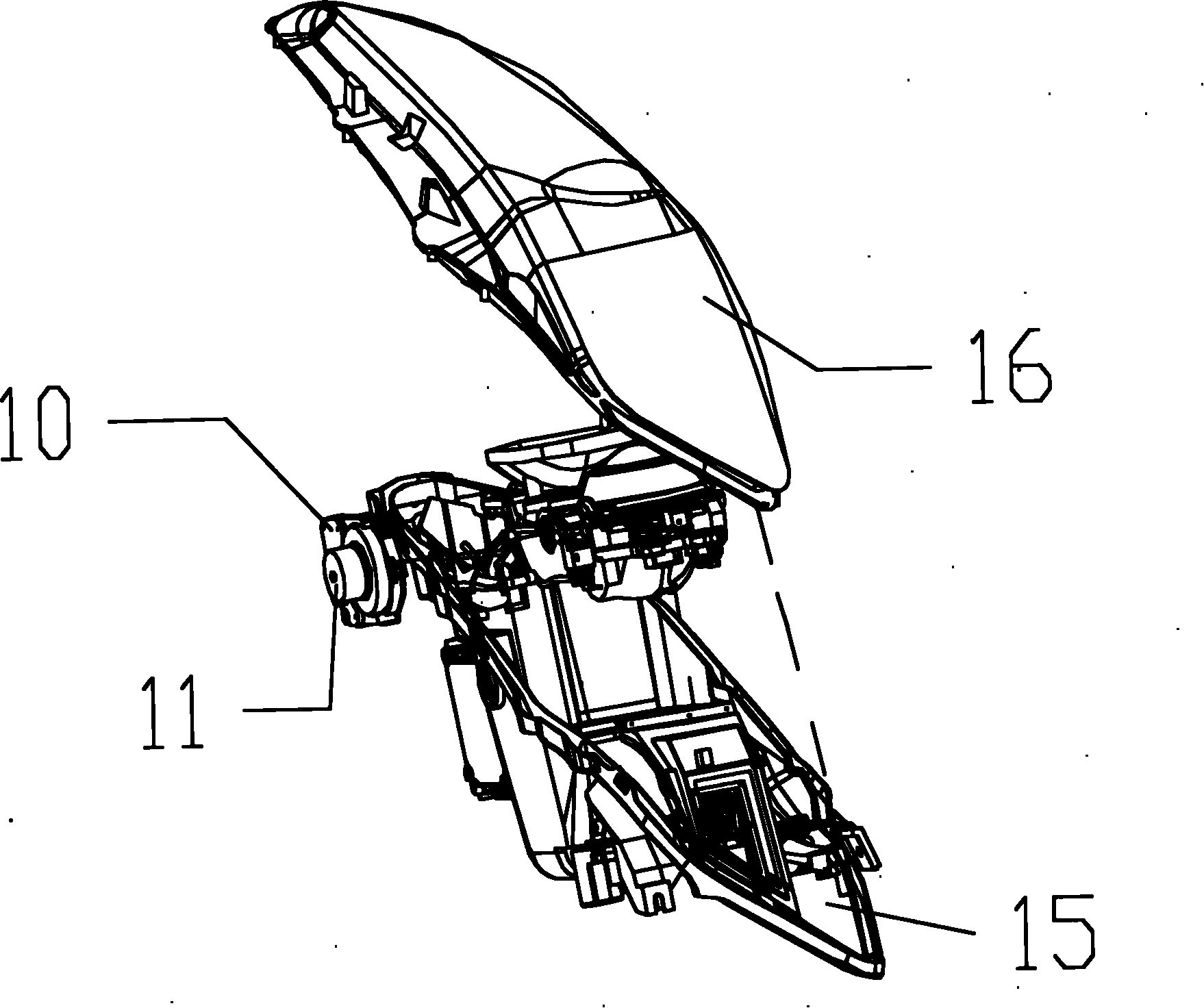

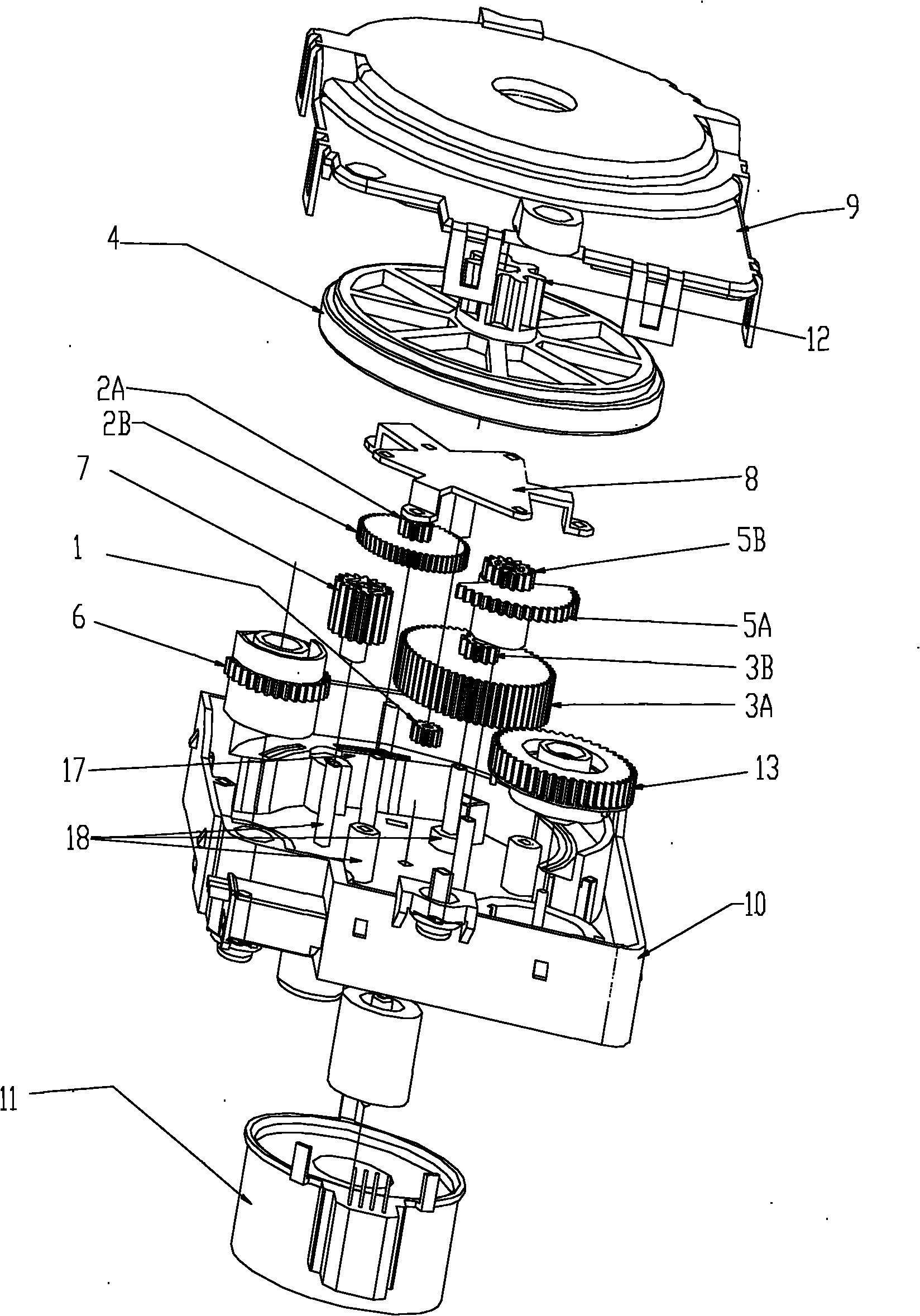

[0013] see Figure 1-Figure 3 , the vehicle headlight steering transmission device of the present embodiment is installed on the lamp bracket 15 through fastening screws, and is connected with the lamp cover 16 . The vehicle headlight steering transmission device includes an upper box cover 9, a lower box cover 10, a centrifugally separated gear transmission mechanism installed in the upper and lower box covers, a DC stepping motor 11 located outside the lower box cover 10, and a gear transmission mechanism of the gear transmission mechanism. The transmission output shaft 12 protrudes outwards from the upper box cover 9 and is connected with the lampshade 16 .

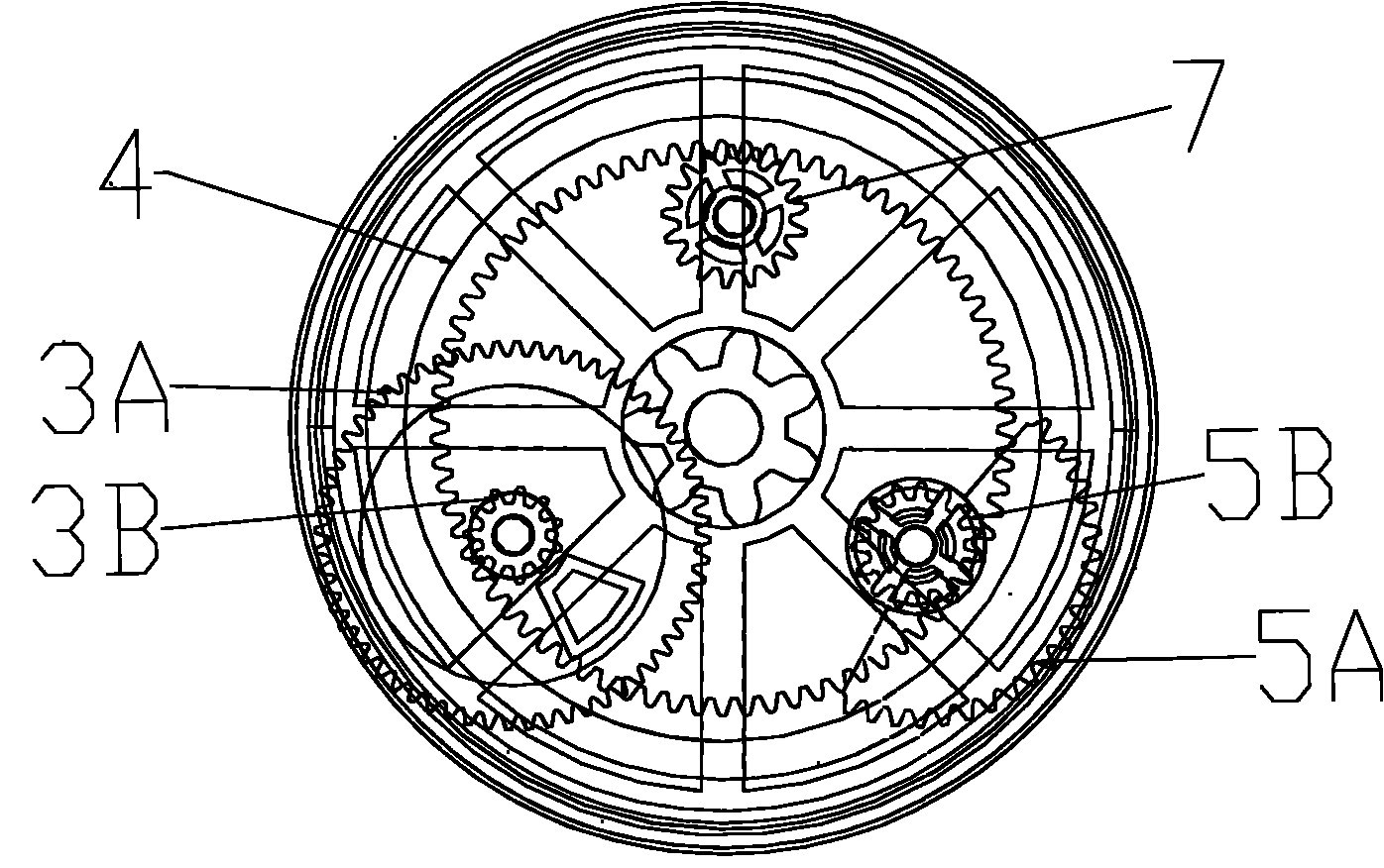

[0014] figure 2 It is a schematic diagram of the dismantling of the assembly structure of the vehicle headlight steering transmission device. The gear transmission mechanism includes the first gear 1, the second gear --- coaxial different-mode gears 2A, 2B, and the third gear --- coaxial different-mode gears 3A, 3B,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com