Strand making, strand combining and rope making integrated rope making machine

A technology of rope-making machine and strand-making machine, which is applied in rope-making auxiliary devices, textiles and papermaking, textile cables, etc., and can solve problems such as the limitation of strand-making twist number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

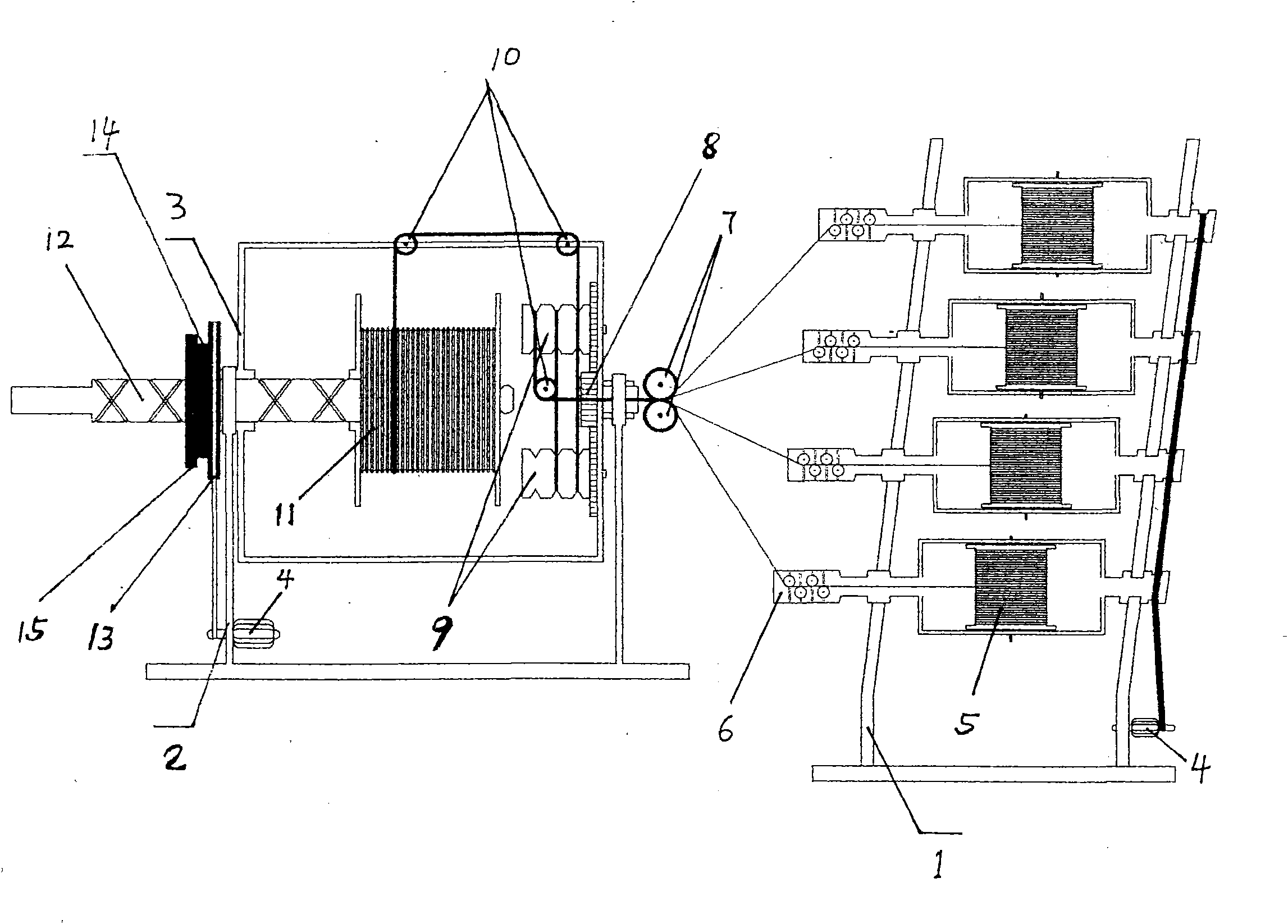

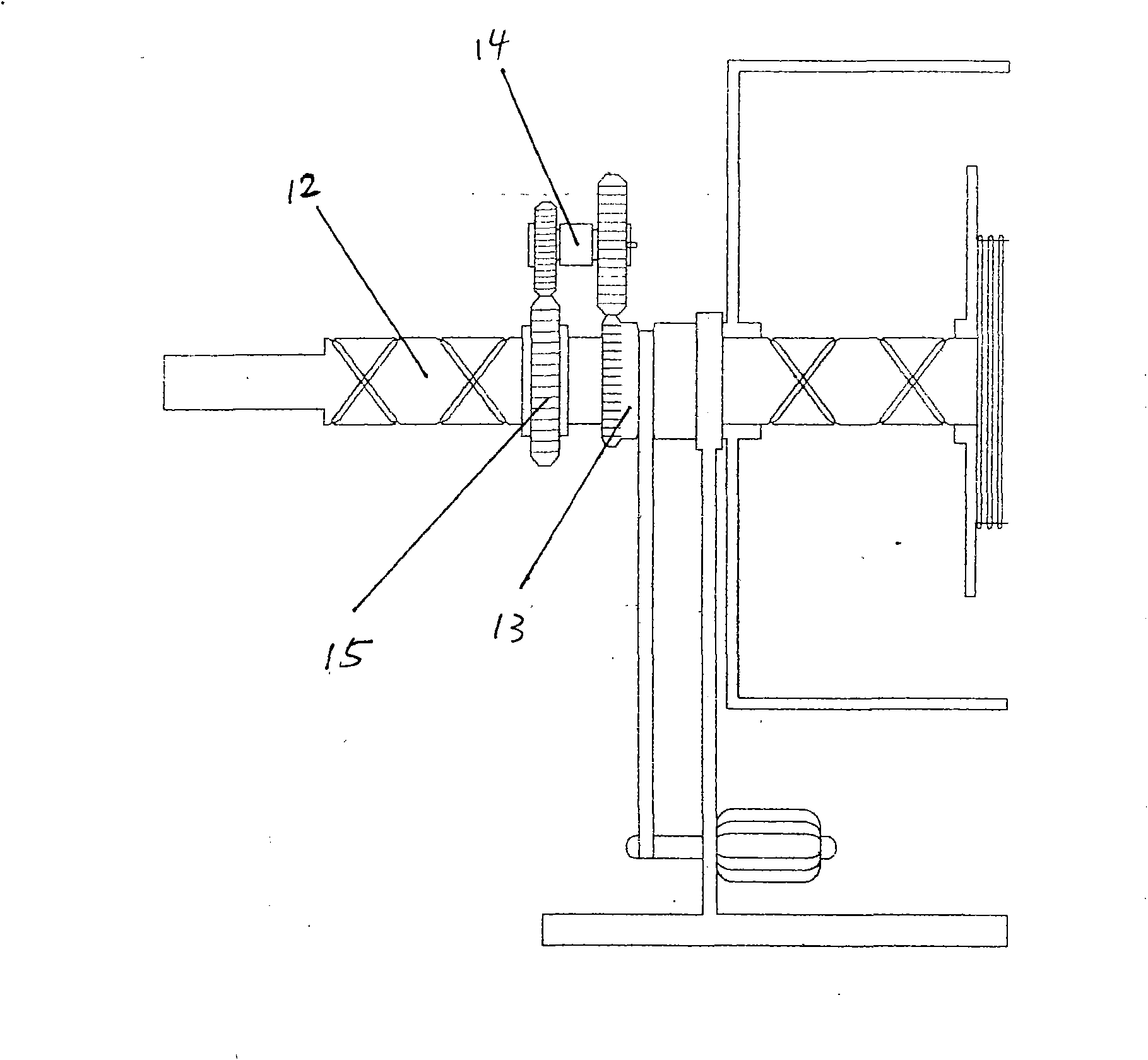

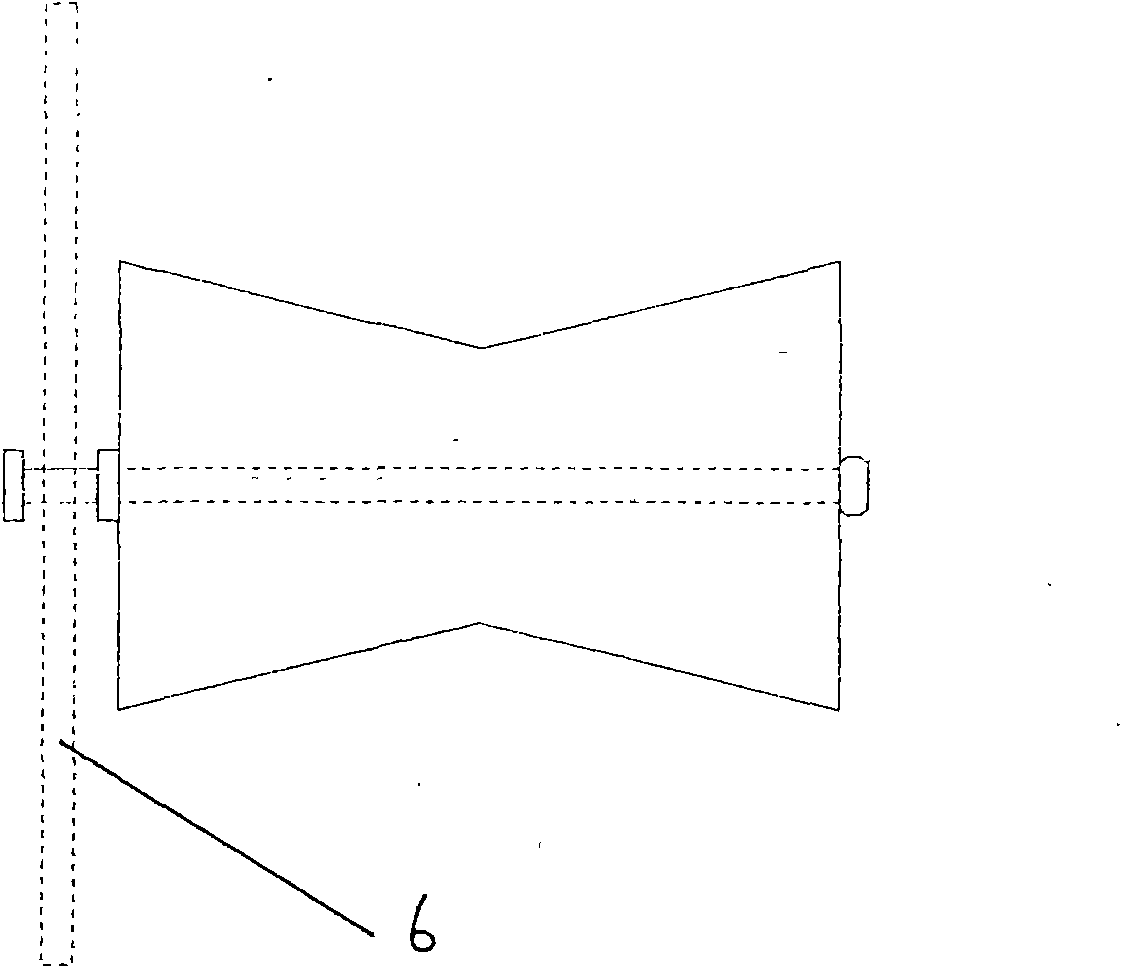

[0010] Such as figure 1 : The motor (4) drives the reel (5) and the outlet buffer valve (6) in the strand making machine (1) to rotate, and the raw material line is slowly "spit out" from the reel (5) through the brake valve. , The strands are made into strands by adjusting its tightness through the outgoing buffer valve (6), and then enter the strands to compress the stranding wheel (7). The rope winding machine (3) rotates the strands into a rope, and the rope is guided by the fixed pulley ( 10) Steering around a pair of twist number-decided helical gears (9) for a few turns, the gear (9) "takes up" the rope, and the twist number helical gear (9) passes through and is mounted on the twisting rope machine (2) The friction rolling between the fixed gear (8) in the inner hole of the bearing at the right end obtains power, and the finished rope continues to be evenly wound on the retractor with back and forth motion function through the two guide fixed pulleys (10) installed above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com