Spot welding technology of vibration-proof photomultiplier lead

A photomultiplier tube and spot welding technology, which is applied in the manufacture of discharge tubes/lamps, circuits, electrical components, etc., can solve problems such as the failure of the tube to be used normally, the increase of the dark current of the tube, and the easy desoldering of the welding part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

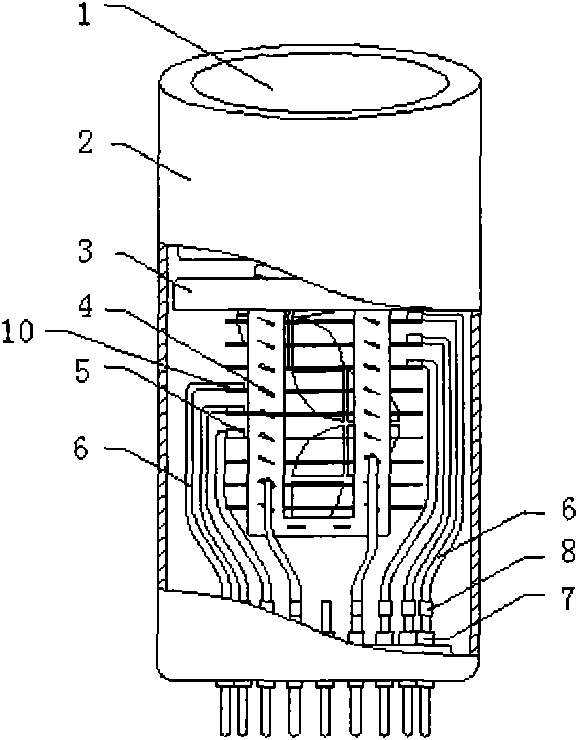

[0010] figure 1 It is a schematic diagram of the composition of the photomultiplier tube, including photocathode 1, tube shell 2, focusing system 3, tube core 4, lead wire and spot welding of each electrode part of the tube core 5, lead wire 6, photomultiplier core column wire 7, lead wire The spot welding place 8 with the stem wire and each electrode part 10 of the tube core.

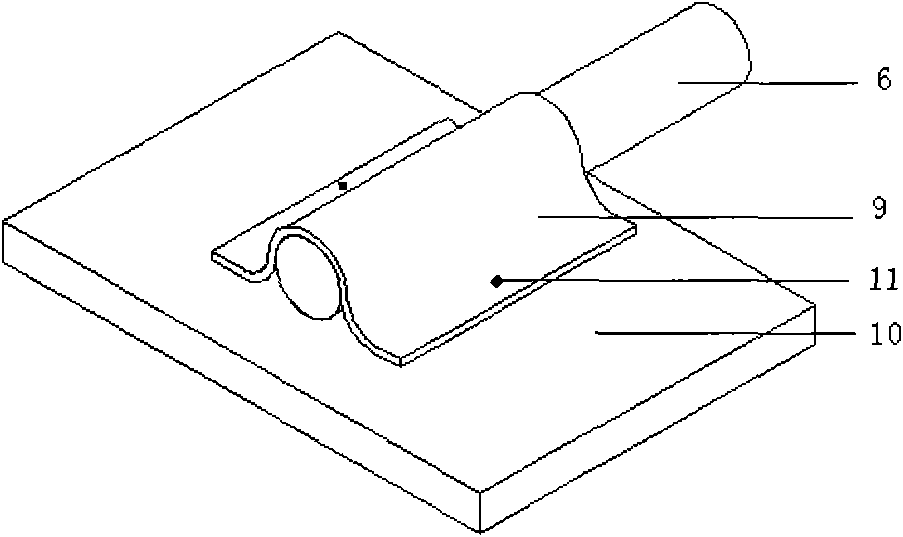

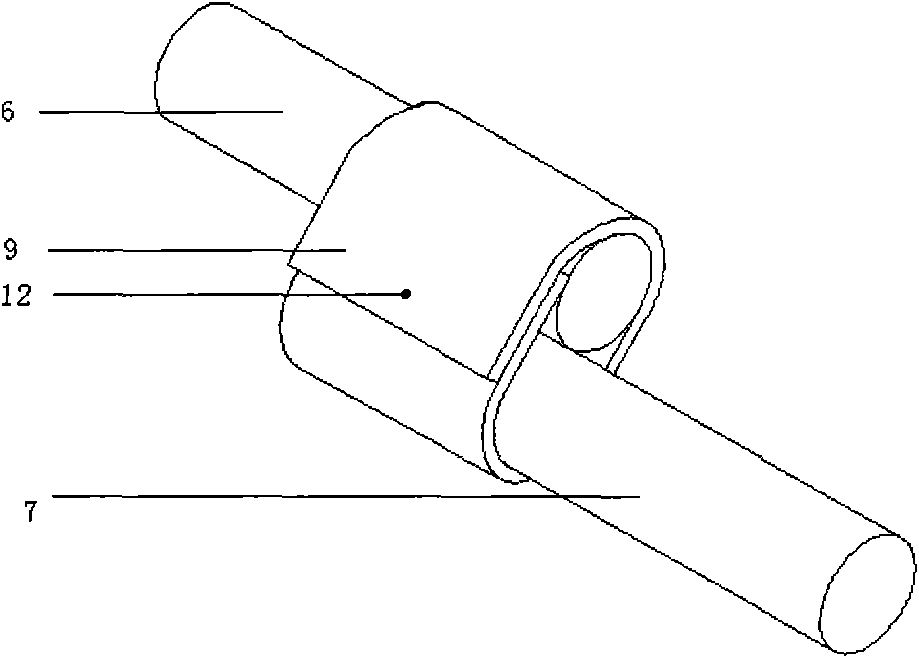

[0011] figure 2 is true figure 1 A further schematic diagram of the spot welding point 5 between the middle lead wire and each electrode part of the tube core, the lead wire 6 is in parallel contact with each electrode part 10 of the tube core, and two solder points are spot welded at the contact point, and the distance between the two solder points is 0.5 mm to 1.5 mm In between, wrap a layer of soft nickel sheet 9 outside the contact afterwards, the width of the soft nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com