Flat plate-type dryer based on solar energy

A flat-panel, solar energy technology, used in dryers, solar thermal power generation, drying and other directions, can solve the problems of excessive heat, scorched dried items, insufficient distance, etc., to avoid direct contact, avoid scorched, Guaranteed drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

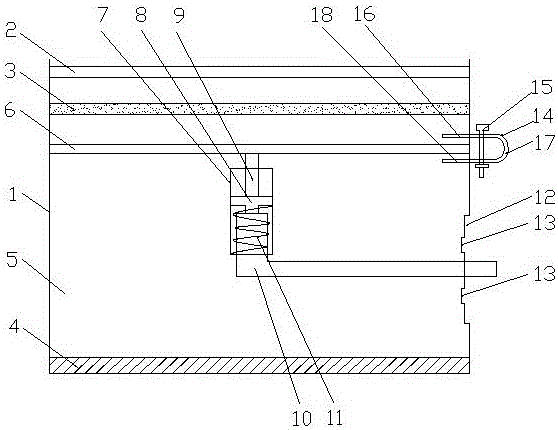

Embodiment 1

[0042] see figure 1 , a flat-plate dryer based on solar energy, including a box body 1, a light-transmitting cover plate 2 arranged on the box body 1, and a heat-absorbing plate 3 arranged in the box body 1, and the heat-absorbing plate 3 is located on the light-transmitting cover Below the plate 2, a bottom plate 4 is fixed on the inner bottom wall of the box body 1, and a drying cavity 5 is formed between the bottom plate 4 and the heat-absorbing plate 3. A spring separation device is arranged in the drying cavity 5, and a spring separation device is connected to the There is a supporting plate 6, the spring separation device includes a housing 7 and a piston 8 arranged in the housing 7, one end of the piston 8 is connected with a push rod 9, and the other end is connected with an L-shaped pull rod 10, the push rod 9 runs through the housing 7 and connects with the supporting plate 6. The L-shaped pull rod 10 is covered with a spring 11, one end of the spring 11 is connected...

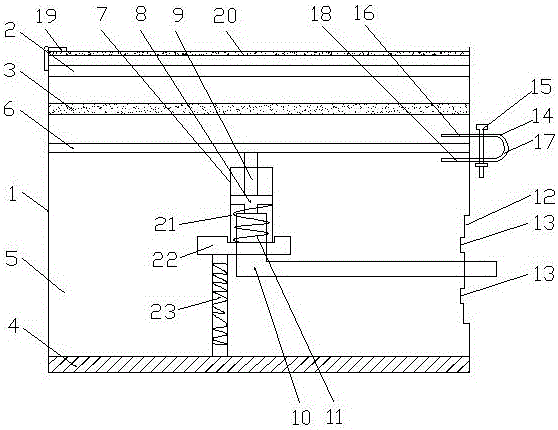

Embodiment 2

[0045] see figure 2 , a flat-plate dryer based on solar energy, including a box body 1, a light-transmitting cover plate 2 arranged on the box body 1, and a heat-absorbing plate 3 arranged in the box body 1, and the heat-absorbing plate 3 is located on the light-transmitting cover Below the plate 2, a bottom plate 4 is fixed on the inner bottom wall of the box body 1, and a drying cavity 5 is formed between the bottom plate 4 and the heat-absorbing plate 3. A spring separation device is arranged in the drying cavity 5, and a spring separation device is connected to the There is a supporting plate 6, the spring separation device includes a housing 7 and a piston 8 arranged in the housing 7, one end of the piston 8 is connected with a push rod 9, and the other end is connected with an L-shaped pull rod 10, the push rod 9 runs through the housing 7 and connects with the supporting plate 6. The L-shaped pull rod 10 is covered with a spring 11, one end of the spring 11 is connecte...

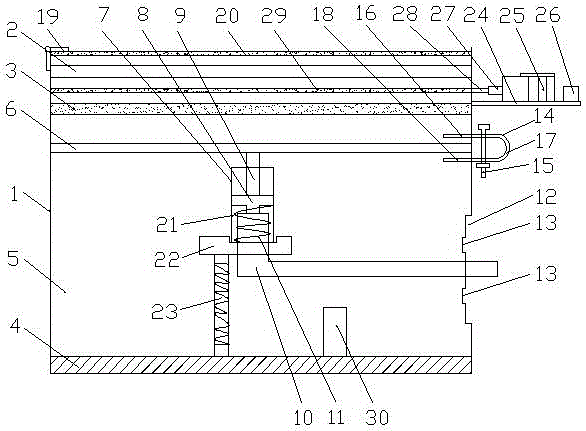

Embodiment 3

[0051] see image 3 , a flat-plate dryer based on solar energy, including a box body 1, a light-transmitting cover plate 2 arranged on the box body 1, and a heat-absorbing plate 3 arranged in the box body 1, and the heat-absorbing plate 3 is located on the light-transmitting cover Below the plate 2, a bottom plate 4 is fixed on the inner bottom wall of the box body 1, and a drying cavity 5 is formed between the bottom plate 4 and the heat-absorbing plate 3. A spring separation device is arranged in the drying cavity 5, and a spring separation device is connected to the There is a supporting plate 6, the spring separation device includes a housing 7 and a piston 8 arranged in the housing 7, one end of the piston 8 is connected with a push rod 9, and the other end is connected with an L-shaped pull rod 10, the push rod 9 runs through the housing 7 and connects with the supporting plate 6. The L-shaped pull rod 10 is covered with a spring 11, one end of the spring 11 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com