Connection hole test structure and method for preparing transmission electron microscopy

A technology for testing structure and connecting hole, which is applied in the field of testing structure of connecting hole and TEM sample preparation, which can solve the problem of inability to measure the thickness of the gluelayer and Barrierseed of the side wall of the connecting hole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In view of the problems mentioned in the background technology, the embodiment of the present invention proposes that if the thickness of the structure used to measure the Gluelayer and Barrier seed in the connection hole test structure can be ensured to be greater than the thickness of the test sample, the above problems can be avoided. Based on this idea, the embodiment of the present invention proposes the following connection hole test structure to avoid the problem that the thickness of the connection hole Gluelayer and Barrier seed cannot be measured because the thickness of the connection hole is smaller than the thickness of the test sample.

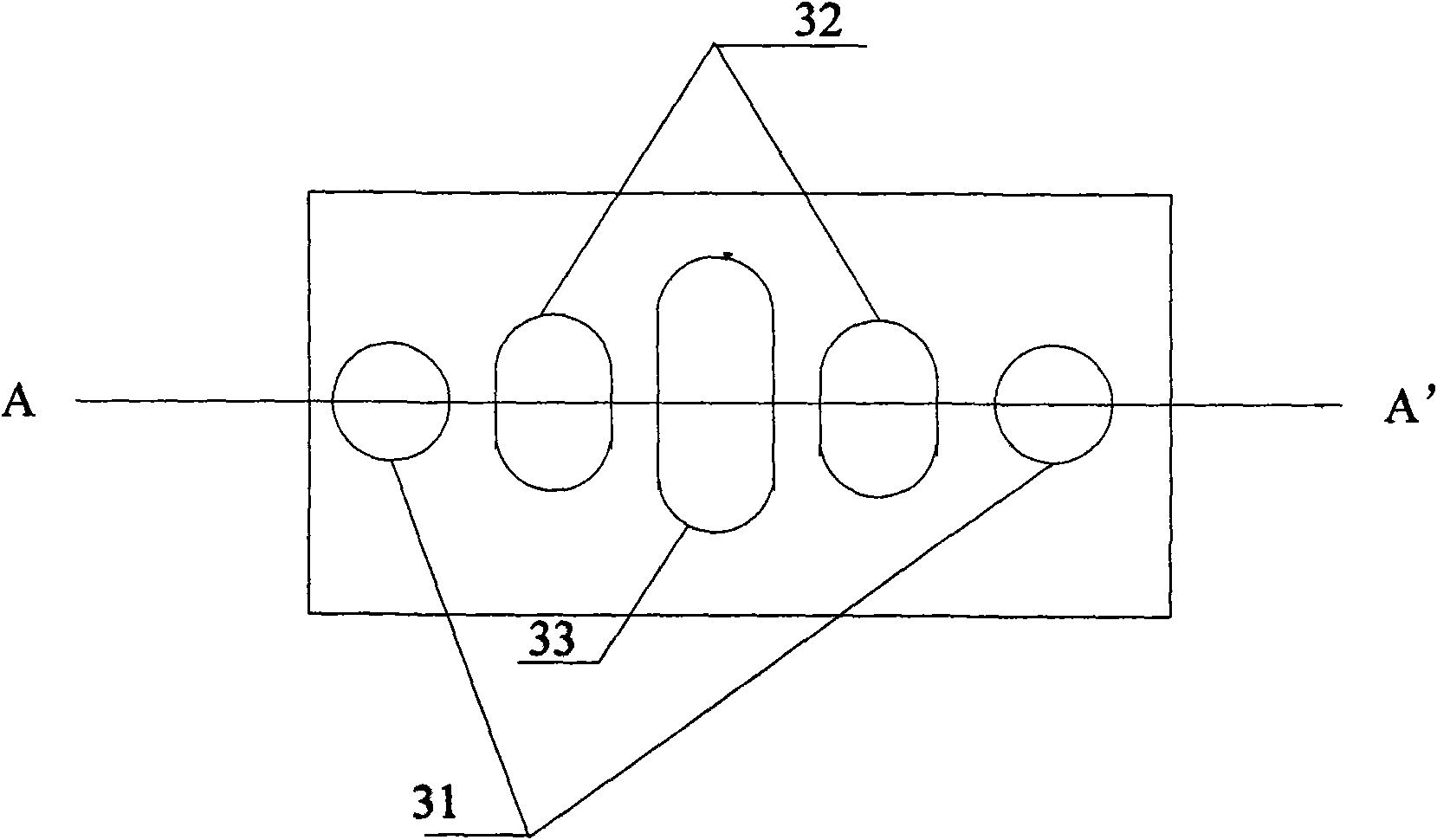

[0015] image 3 It is a top view of the connection hole test structure in the embodiment of the present invention. In combination with this figure, the connection hole test structure proposed in the embodiment of the present invention includes: the original hole 31, the calibration hole 32 and the measurement hole 33;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com