Bending cylinder block

A roll bending and cylinder block technology, which is applied in the field of work rolls of six-high cold rolling mills, can solve the problem of affecting the service life of the bending roll cylinder block and the shape and quality of the strip steel plate, the uneven force of the bearing seat of the work roll, and the impact on the shape and quality of the strip steel plate Quality and other issues, to achieve the effect of improving plate shape and surface quality, reasonable cost, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

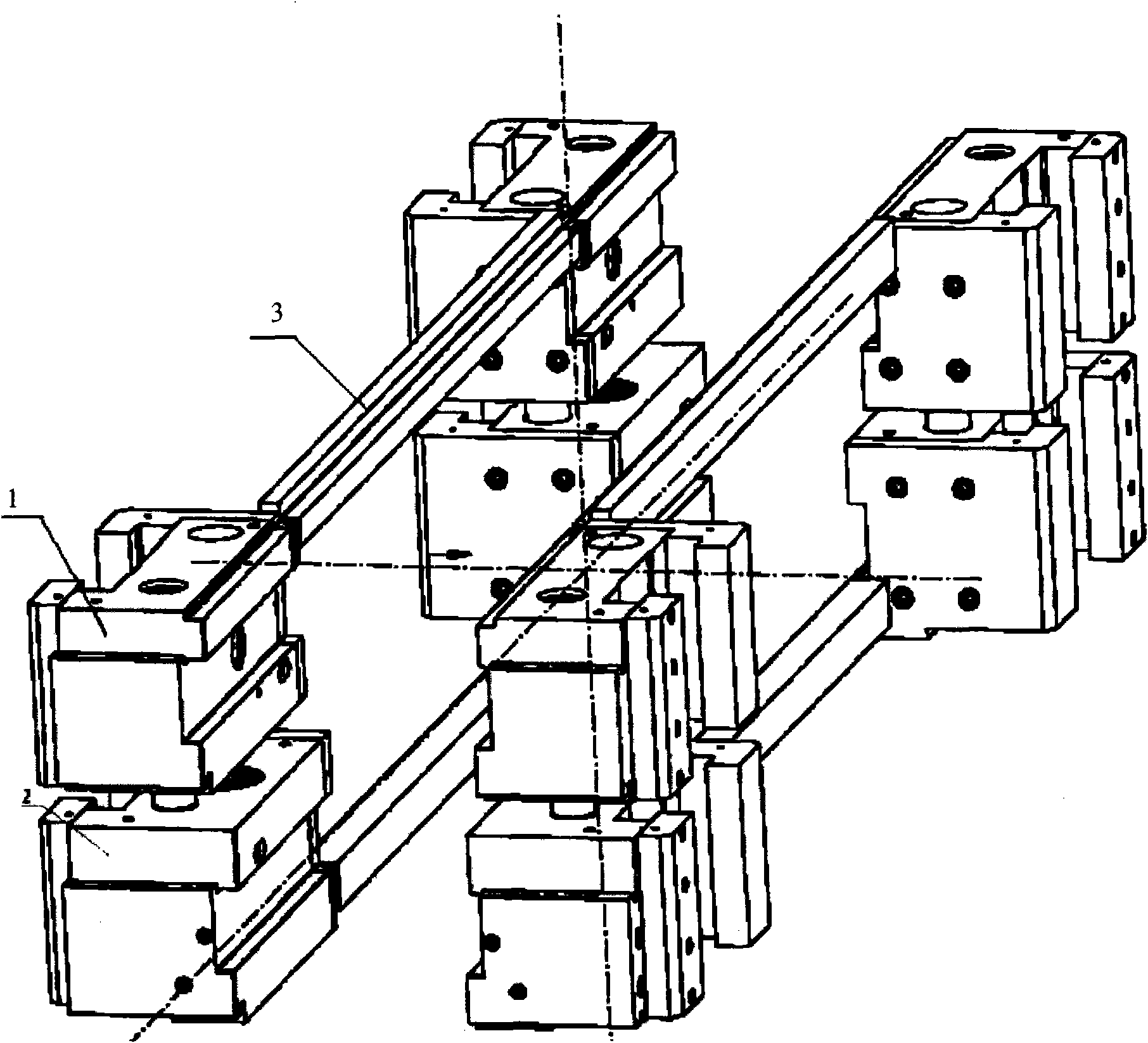

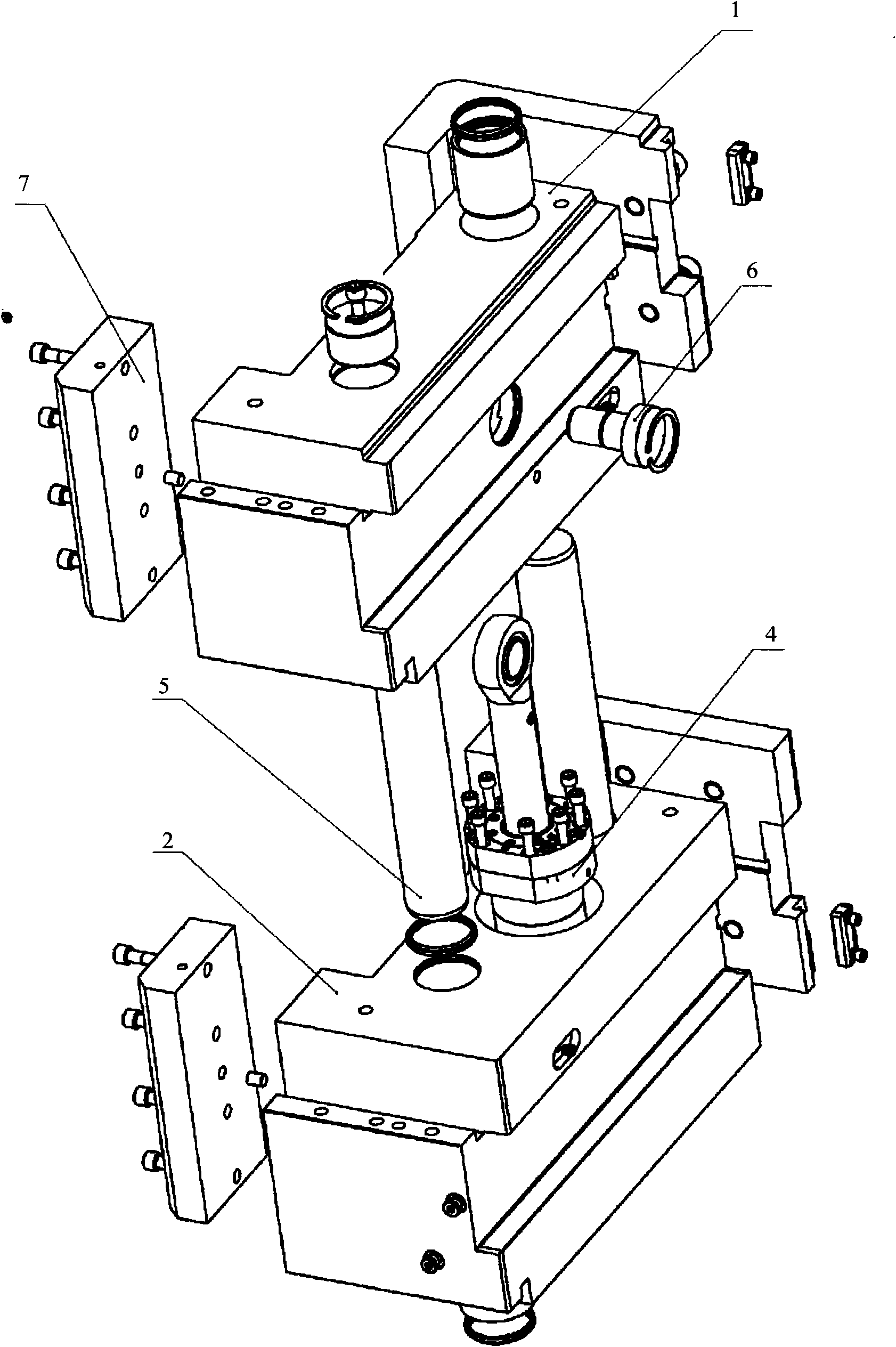

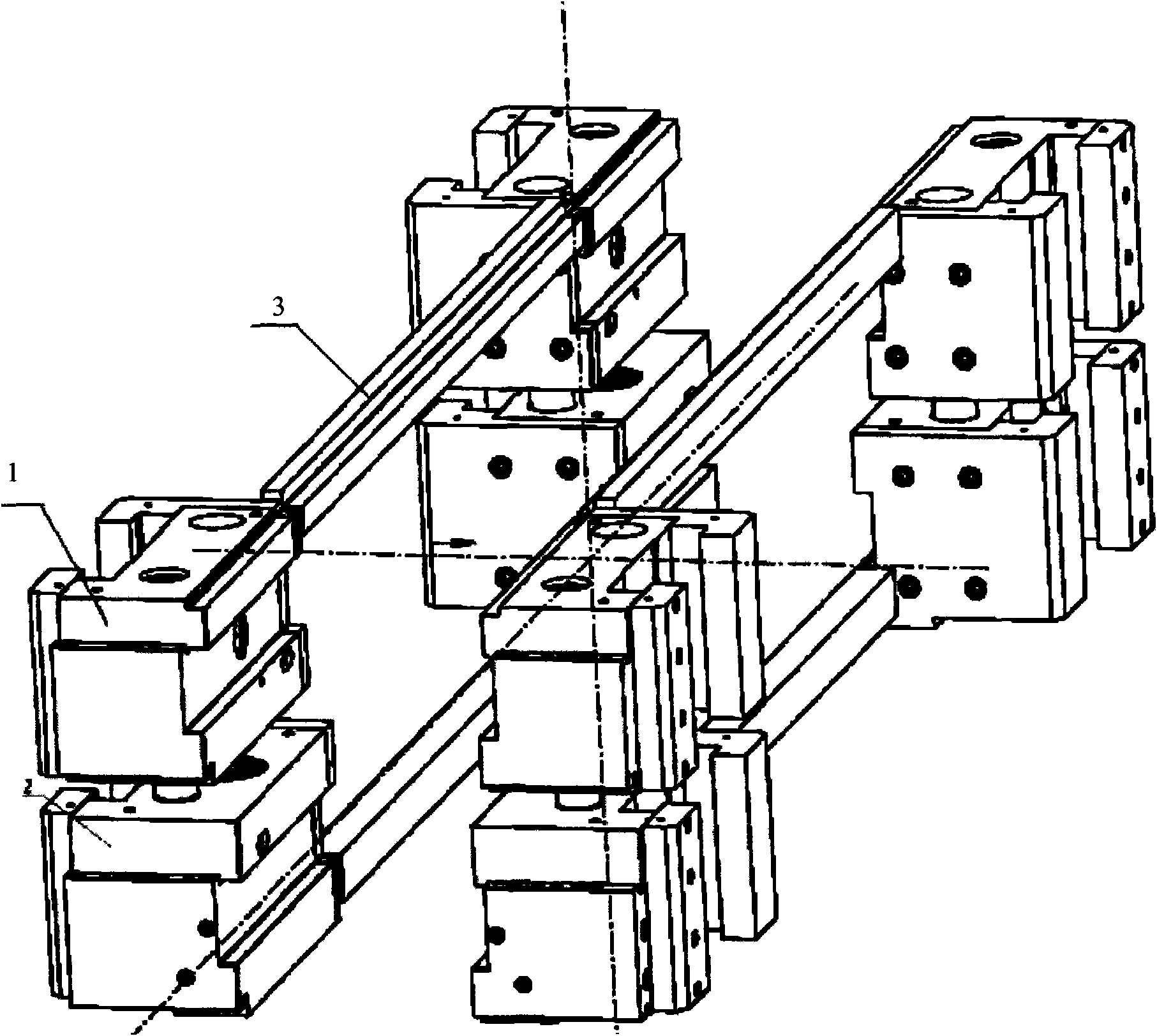

[0021] see figure 1 , 2 As shown, the roll bending block of the present invention includes: an upper bending block 1 , a lower bending block 2 and a bending hydraulic cylinder 4 . The roll bending hydraulic cylinder 4 is fixed on the lower bending roll cylinder block 2, and an articulated bearing is installed on its upper end, which is connected with the upper bending roll cylinder block 1 through a hinged fixing pin 6; the upper bending roll cylinder block 1 and the lower bending roll cylinder block The two pieces move relative to each other through the expansion and contraction of the roll bending hydraulic cylinder 4 .

[0022] The upper bending cylinder block 1 and the lower bending cylinder block 2 are respectively clamped on the supporting cylinder body through detachable clamping plates 7, so as to ensure that the upper bending cylinder block 1 and the lower bending cylinder block 2 can only move along the supporting cylinder. The cylinder moves up and down.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com