Underwater salvage grab bucket

A technology of underwater salvage and bucket teeth, which is applied in ship salvage, ships, transportation and packaging, etc., can solve the problems of high labor intensity, difficult installation of bucket teeth, high risk, etc., and achieve simple design, easy rope change, and even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

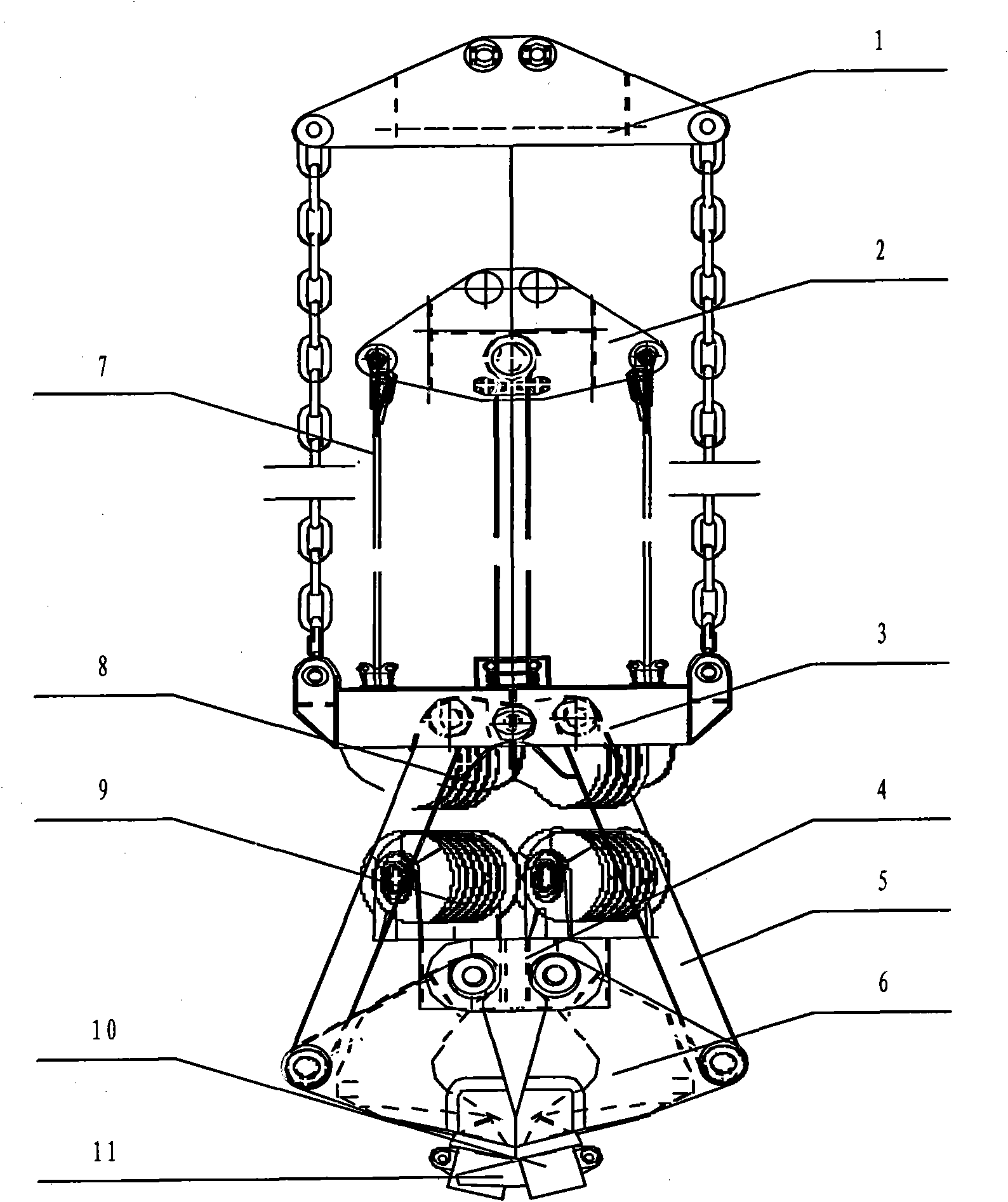

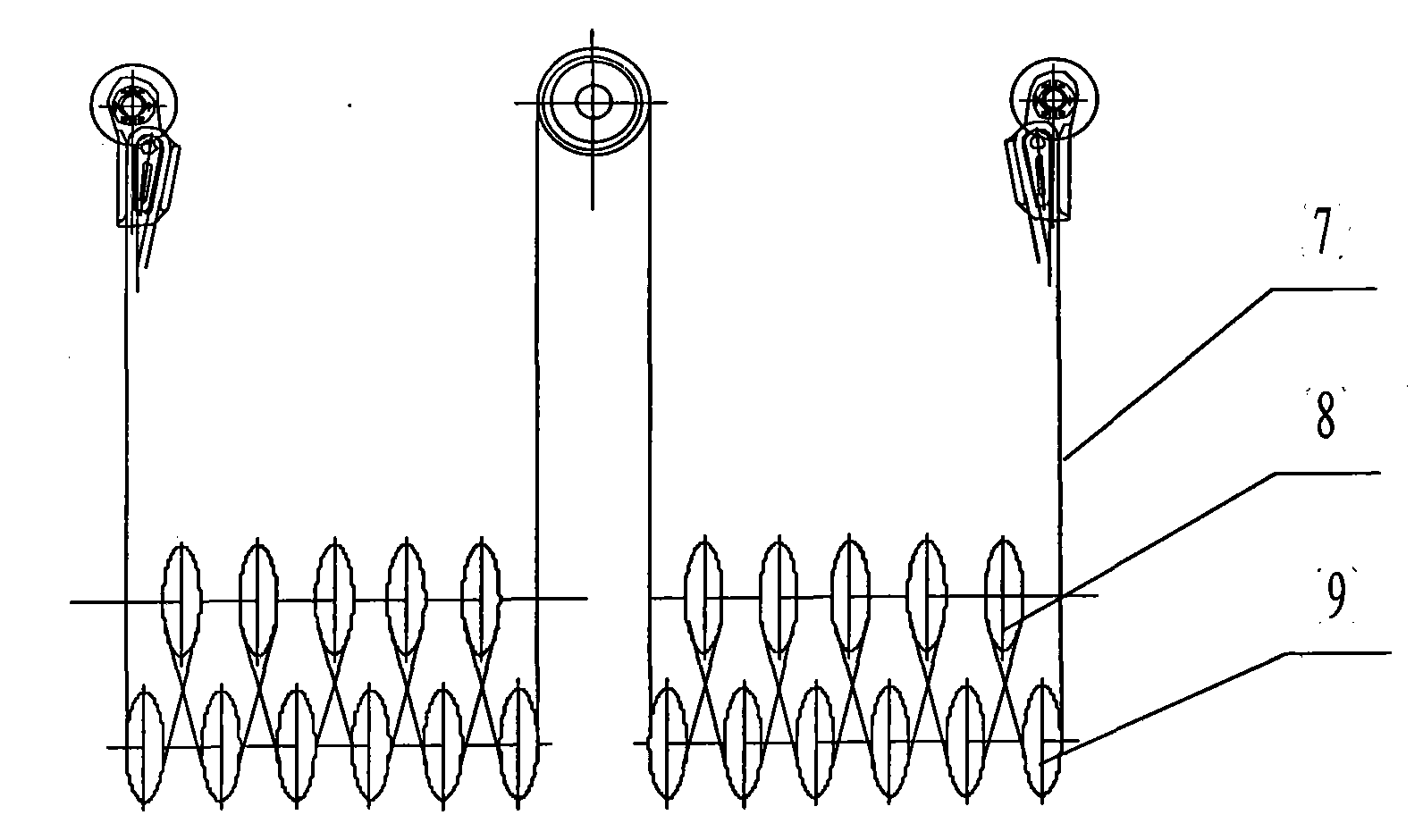

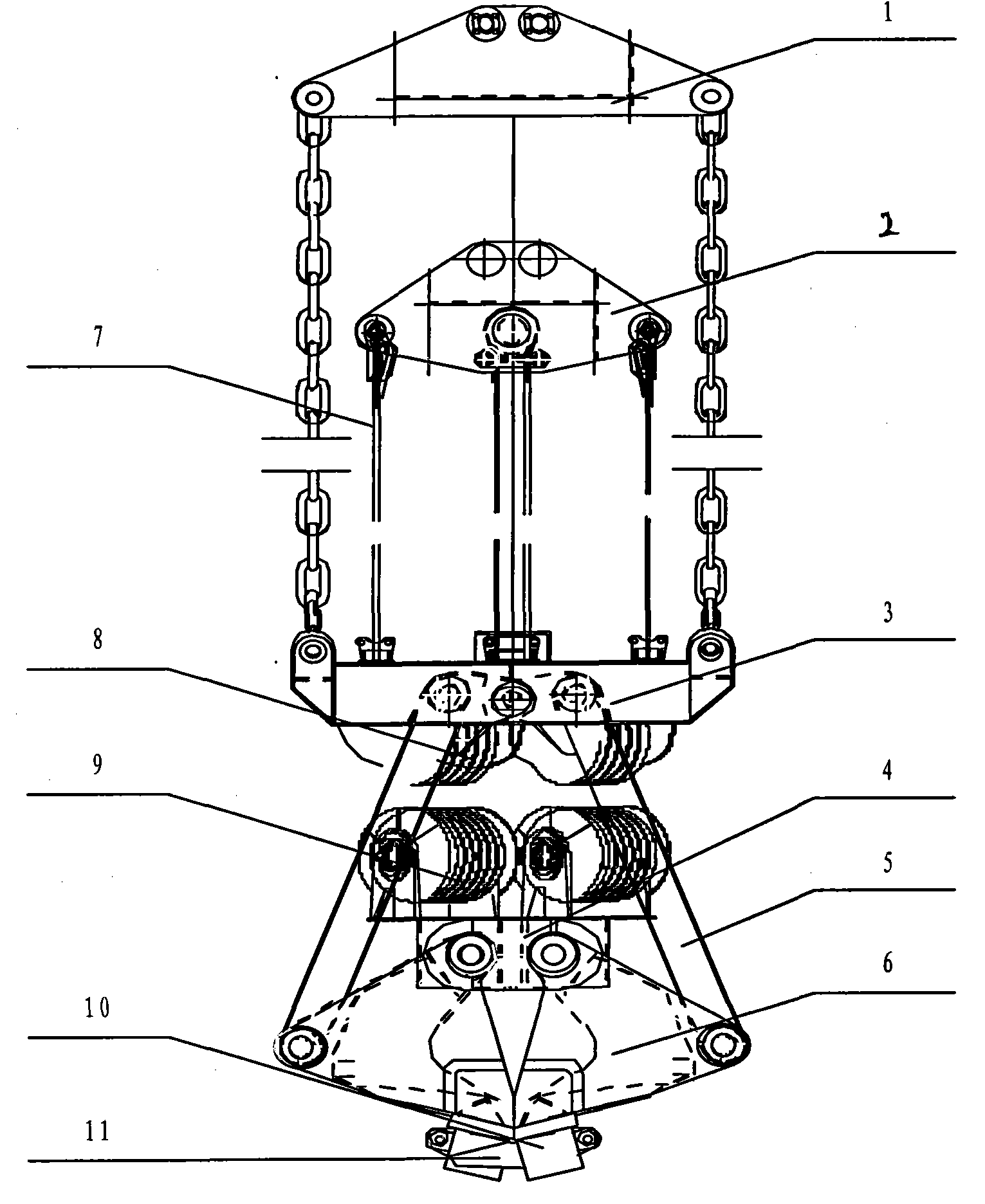

[0010] Example 1, see figure 1 , 2 , processed into a gravity balance beam 1 and an opening and closing balance beam 2, a bucket head assembly 3 is installed below the gravity balance beam 1, and the two are connected by a chain for lifting the grab and maintaining the stability of the grab in the air; the bucket head The assembly 3 is connected with the strut assembly 5 through the pin shaft, the strut assembly 5 is connected with the bucket body 6 through the pin shaft, and the bucket body 6 is connected with the middle beam assembly 4 through the pin shaft, so that the bucket head assembly 3, the middle beam assembly The beam assembly 4, the strut assembly 5, and the bucket body 6 are connected together by a pin shaft and can rotate relatively; On the assembly 4, the pulley can rotate on the pulley shaft; then the opening and closing balance beam 2 is connected with the bucket head pulley block 8 and the center beam pulley block 9 through the opening and closing steel wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com