Method for preparing nano ceramic fibers

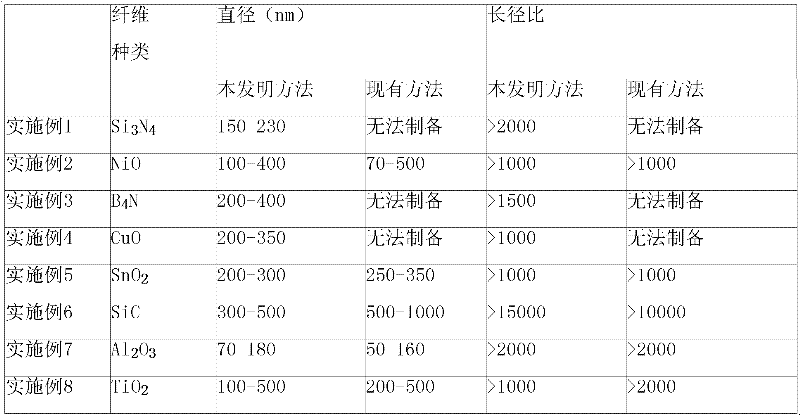

A nano-ceramic fiber and nano-fiber technology, which is applied in fiber processing, spinning solution preparation, textile and papermaking, etc., can solve the problems of few nano-ceramic fibers, can not meet actual needs, and limit the selection of materials. The effect of uniform distribution, high aspect ratio and high product success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of nano ceramic fiber of the present invention is implemented according to the following steps:

[0015] Step 1: By volume percentage, take 3%-15% of ceramic nanoparticles with a particle size of 10nm-300nm, 5%-30% of spinnable polymer, 0.5%-5% of dispersant, and the rest as solvent, with a total volume of 100%.

[0016] Selection of ceramic nanoparticles: titanium dioxide, zinc oxide, magnesium oxide, calcium oxide, zirconium dioxide, vanadium pentoxide, iron oxide, cobalt oxide, nickel oxide, aluminum oxide, manganese dioxide, boron oxide, tin dioxide, lead oxide , arsenic oxide, chromium oxide, cadmium oxide, silicon carbide, silicon nitride, boron nitride, inorganic carbide, and inorganic nitride.

[0017] Spinnable polymer selection: polyvinylpyrrolidone, polyethylene glycol, polyvinyl butyral, sodium polyacrylate, polymethyl methacrylate, polyvinyl alcohol, cellulose, polycarbonate, m-phenylene One of phthalamide, elastic polypeptide, reco...

Embodiment 1

[0030] By volume percentage, Si with a particle size of 10nm 3 N 4 Nanoparticles 3%, polyvinyl alcohol (PVA) 10%, cetyltrimethylammonium bromide 0.5% and 86.5% deionized water for a total volume of 100%. Add polyvinyl alcohol (PVA) into deionized water, heat in a water bath at 85°C and stir magnetically to obtain a PVA solution with a certain viscosity; Si 3 N 4 Nanoparticles and cetyltrimethylammonium bromide were added to the PVA solution, kept at a constant temperature of 85°C in a water bath, then the solution was dispersed, and stirred continuously for 1h, and then the mixed solution was ultrasonically dispersed for 0.5h, and heated at 50 ℃ constant temperature swelling for 0.5h, forming Si with uniform composition 3 N 4 / PVA spinning solution. Pour the spinning solution into the syringe, and use the flattened injection needle as the capillary for jetting fine flow. During the electrospinning process, the voltage is 10kV, the collection distance is 10cm, the spinning...

Embodiment 2

[0033]By volume percentage, 6% of NiO nanoparticles with a particle size of 300nm, 5% of polyvinyl butyral (PVB), 5% of ammonium citrate and 84% of deionized water are taken, and the total volume is 100%. Add polyvinyl butyral (PVB) to ethanol, heat in a water bath at 75°C and stir magnetically to obtain a PVB solution with a certain viscosity; add NiO nanoparticles and ammonium citrate to the PVB solution, Maintain a constant temperature of 50°C in the medium, then disperse the solution, keep stirring for 1h, then ultrasonically disperse the mixed solution for 0.5h, and swell at a constant temperature of 75°C for 0.5h to form a NiO / PVB spinning solution with uniform composition. Pour the spinning solution into the syringe, and use the flattened injection needle as the capillary for jetting fine flow. During the electrospinning process, the voltage is 40kV, the collection distance is 30cm, the spinning solution propulsion speed is 2.5mL / h, and the ambient temperature is 50°C ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com