Jacket riser mounting method and special riser component thereof

A technology of riser assembly and installation method, which is applied in the directions of earth-moving drilling, wellbore/well components, production fluid, etc., can solve the problems of difficult alignment operation, increased workload, long construction time, etc. The effect of good alignment and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

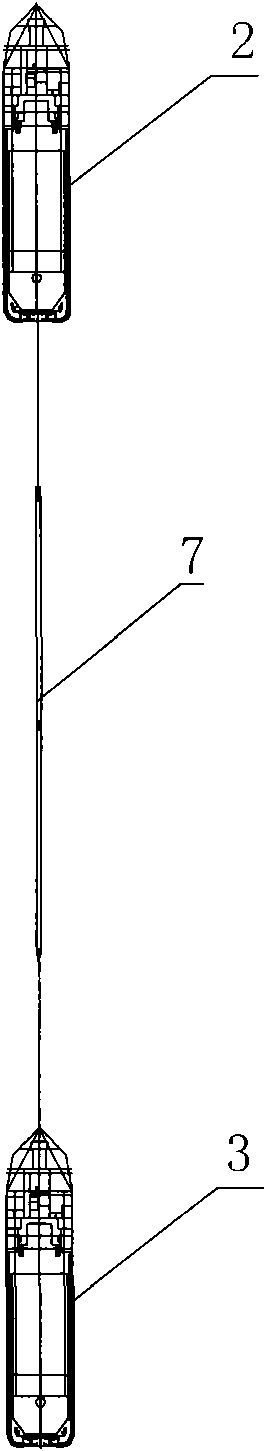

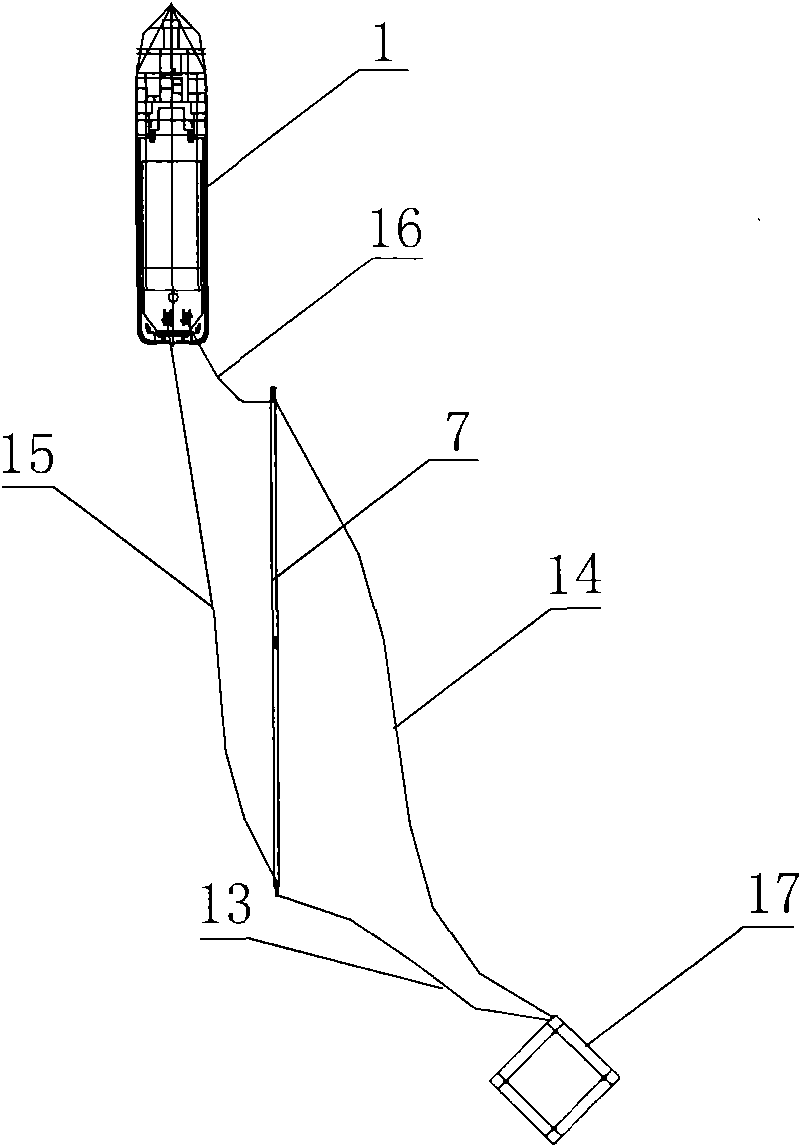

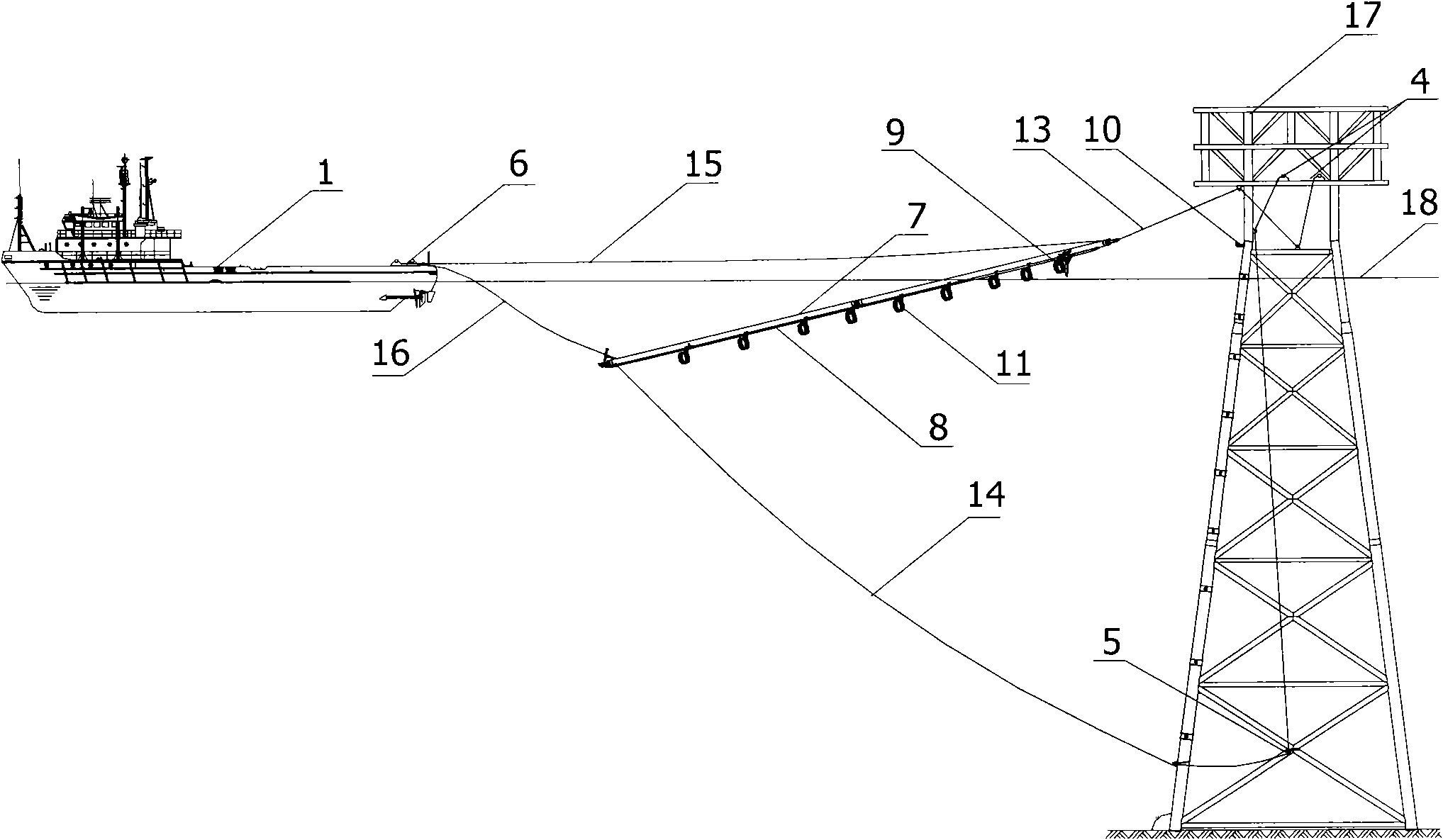

[0040] Embodiment 1. Riser assembly for installing deepwater jacket riser

[0041] The riser assembly provided by the present invention for installing the riser of the deep water jacket is as Figure 10 As shown, a standpipe 8 and a floating pipe 7 are included. One end of the standpipe 8 is provided with a suspension flange 9, specifically the standpipe 8 is sleeved in the suspension flange 9, and then the suspension flange 9 and the standpipe 8 are welded. Suspension flange is made up of the annular plate that is welded on the standpipe 8 and reinforcing plate. Since the upper end of the deep-water jacket 20 is provided with a fixed pipe clamp 10, one end of the fixed pipe clamp 10 is clamped on the deep-water jacket 20, and the other end is clamped on the riser 8. When the fixed pipe clamp 10 is clamped on the riser 8 , the suspension flange 9 just sits on the fixed pipe clamp 10. This can effectively prevent the riser 8 from being displaced downward.

[0042] There are...

Embodiment 2

[0051] Embodiment 2, installation method of deepwater jacket riser

[0052] 1. On-site investigation:

[0053] After the main operation ship 1 arrives at the construction site, it is necessary to conduct on-site investigation: clear the obstacles around the position where the riser 8 is to be installed, clean up the seabed mud surface at the lower elbow of the position where the riser 8 is to be installed, and measure the pre-installation of the jacket 20. The position of riser card 11, and clean up the marine life of riser card 11 positions. A fixed pipe clip 10 that can be connected to the riser 8 is installed on the upper end of the jacket 20. There is an orientation mark on the fixed pipe clip 10. When the riser 8 is installed, this mark corresponds to the orientation mark of the suspension flange 9 on the standpipe 8. . When the fixed tube clip is aligned with the orientation mark on the suspension flange, the orientation of the riser can be determined.

[0054] 2. Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com