Vibration reduction inlet pipe for gasoline engine

A gasoline engine and air intake pipe technology, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as reducing carburetor vibration, and achieve the effects of improving stability, obvious attenuation, and avoiding uneven concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

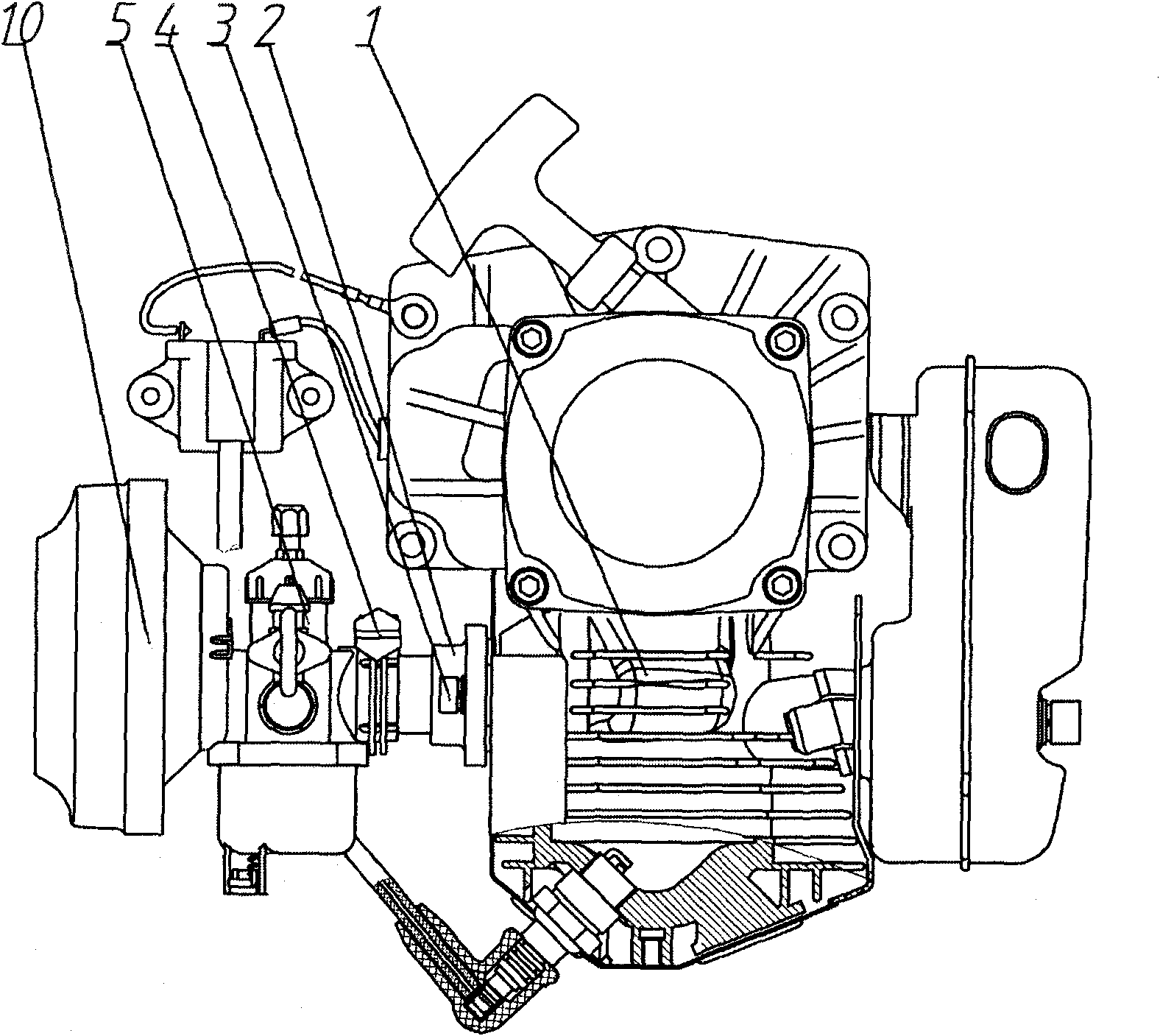

[0017] like figure 1 , figure 2 , image 3 , Figure 4 As shown, according to the gasoline engine of the present invention, the cylinder body 1 is connected with the damping intake pipe 2 through the screw 3, the damping intake pipe 2 is connected with the carburetor 5 through the bolt 4, and the carburetor 5 is connected with the air filter 10.

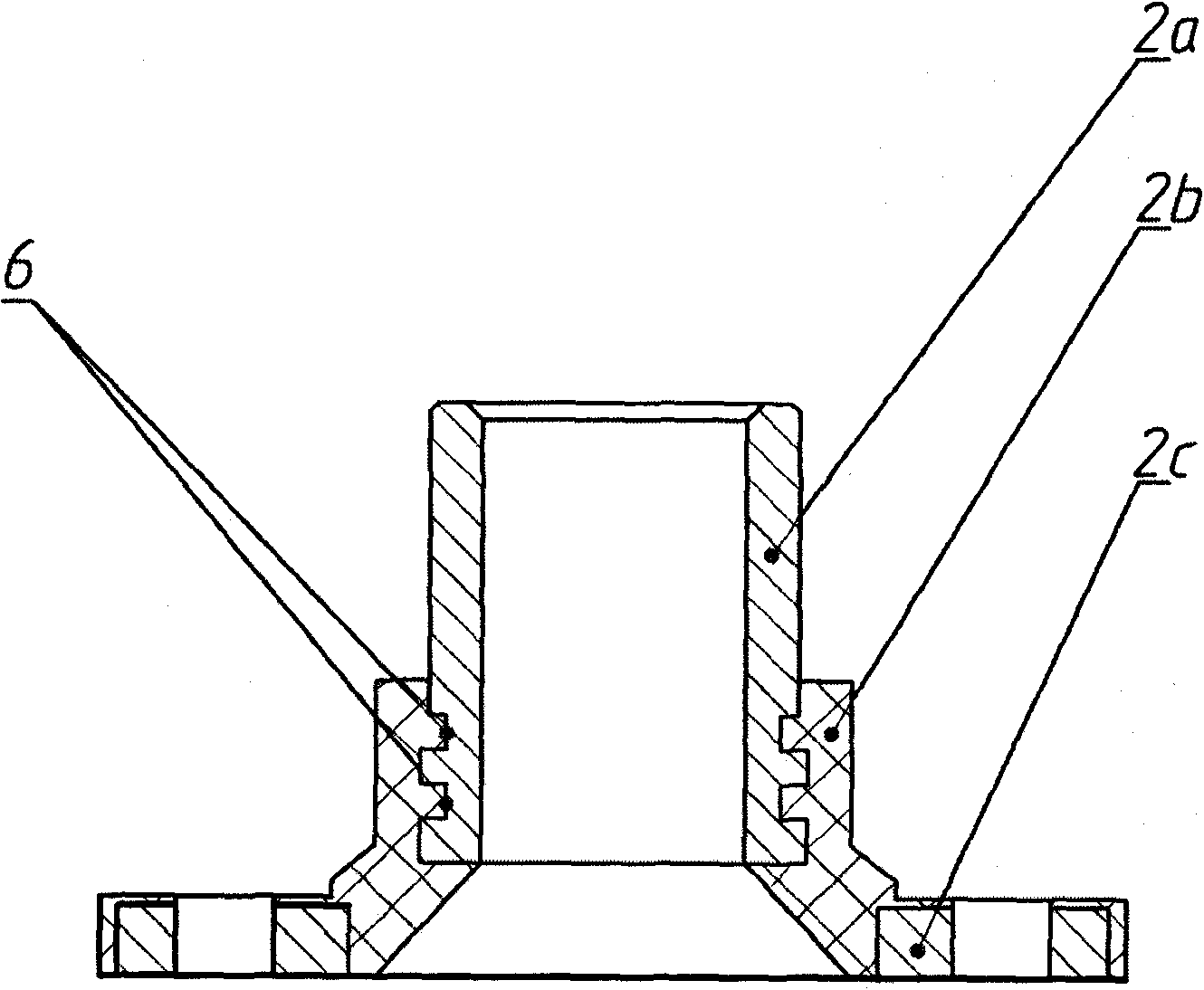

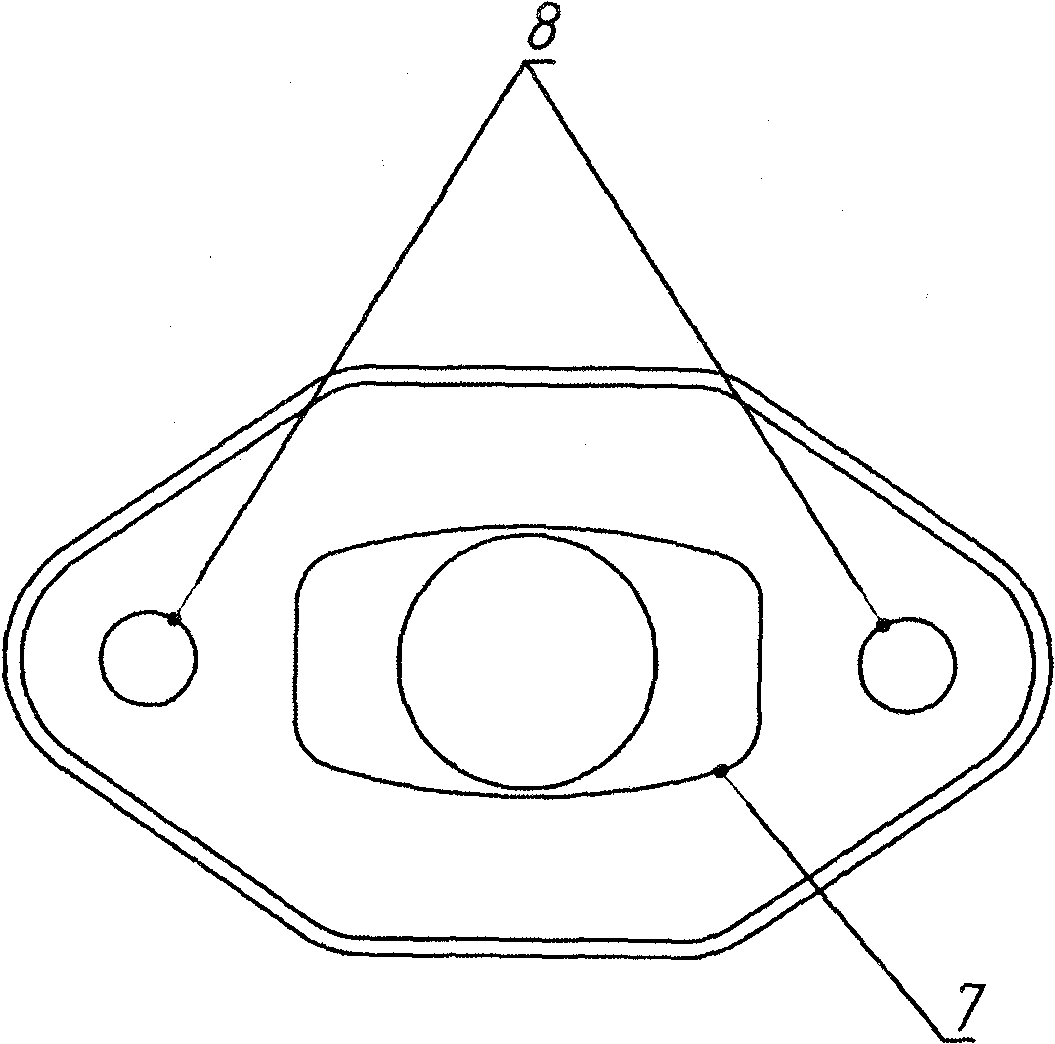

[0018] The damping intake pipe 2 includes a steel pipe 2a, a plastic sleeve 2b, and a steel plate 2c. The steel pipe 2a is embedded in one end of the plastic sleeve 2b, and the other end of the plastic sleeve 2b is embedded with a steel plate 2c, so that the steel pipe 2a and the steel plate 2c are flexibly connected through the plastic sleeve 2b. In one piece, the outer wall of the inlaid end of the steel pipe 2a is provided with a toothed groove 6, the steel plate 2c is provided with a vent hole 7 and a screw hole 8, and the cylinder body 1 is provided with a cylinder air inlet 9.

[0019] Since the plastic sleeve 2b is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com