Oil-free lubrication plunger pump

A technology of oil-free lubrication and plunger pumps, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machinery, etc., can solve the problems of no heat dissipation device, pollution of the transported liquid, and unfavorable health, so as to achieve convenient and good cleaning. The effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

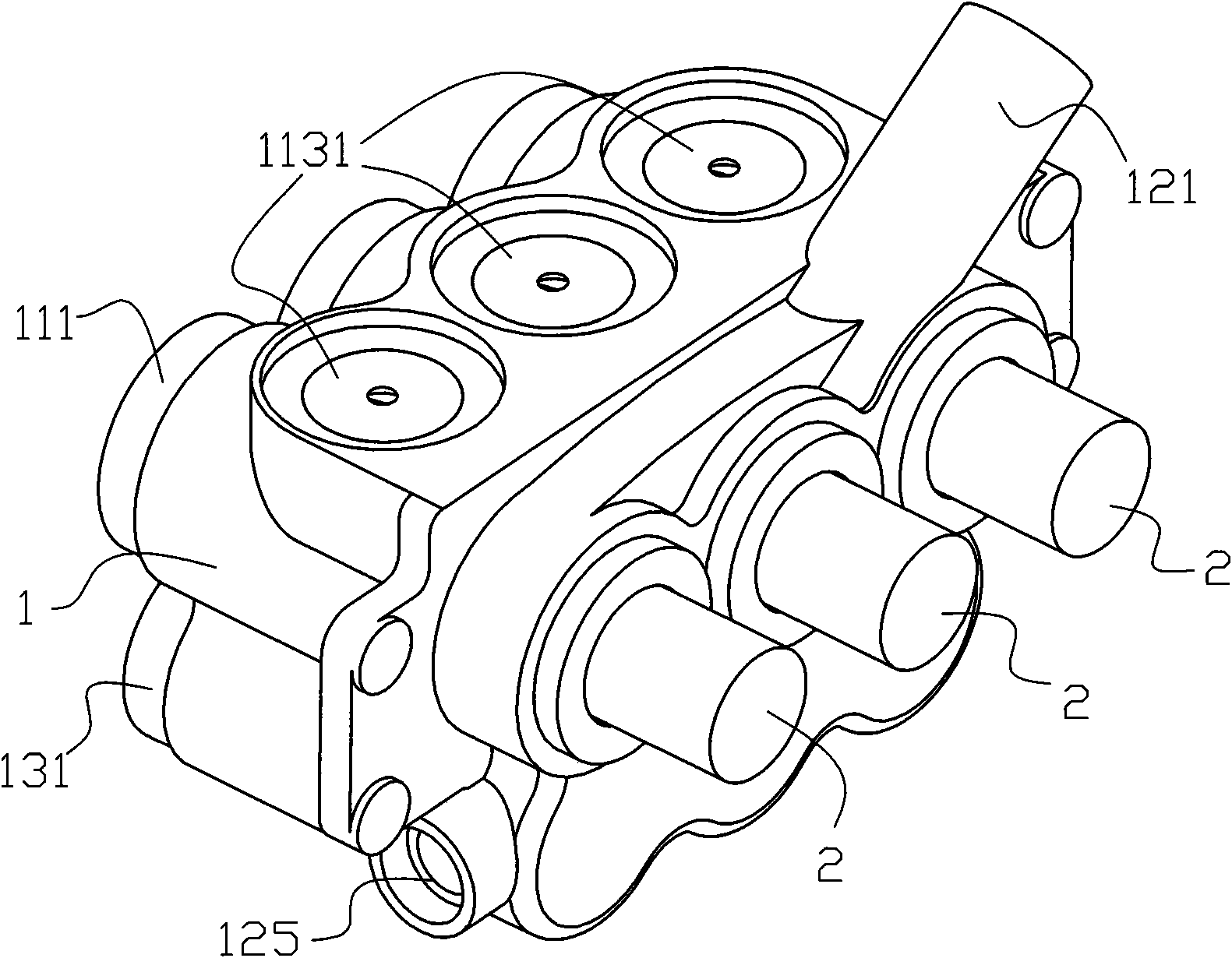

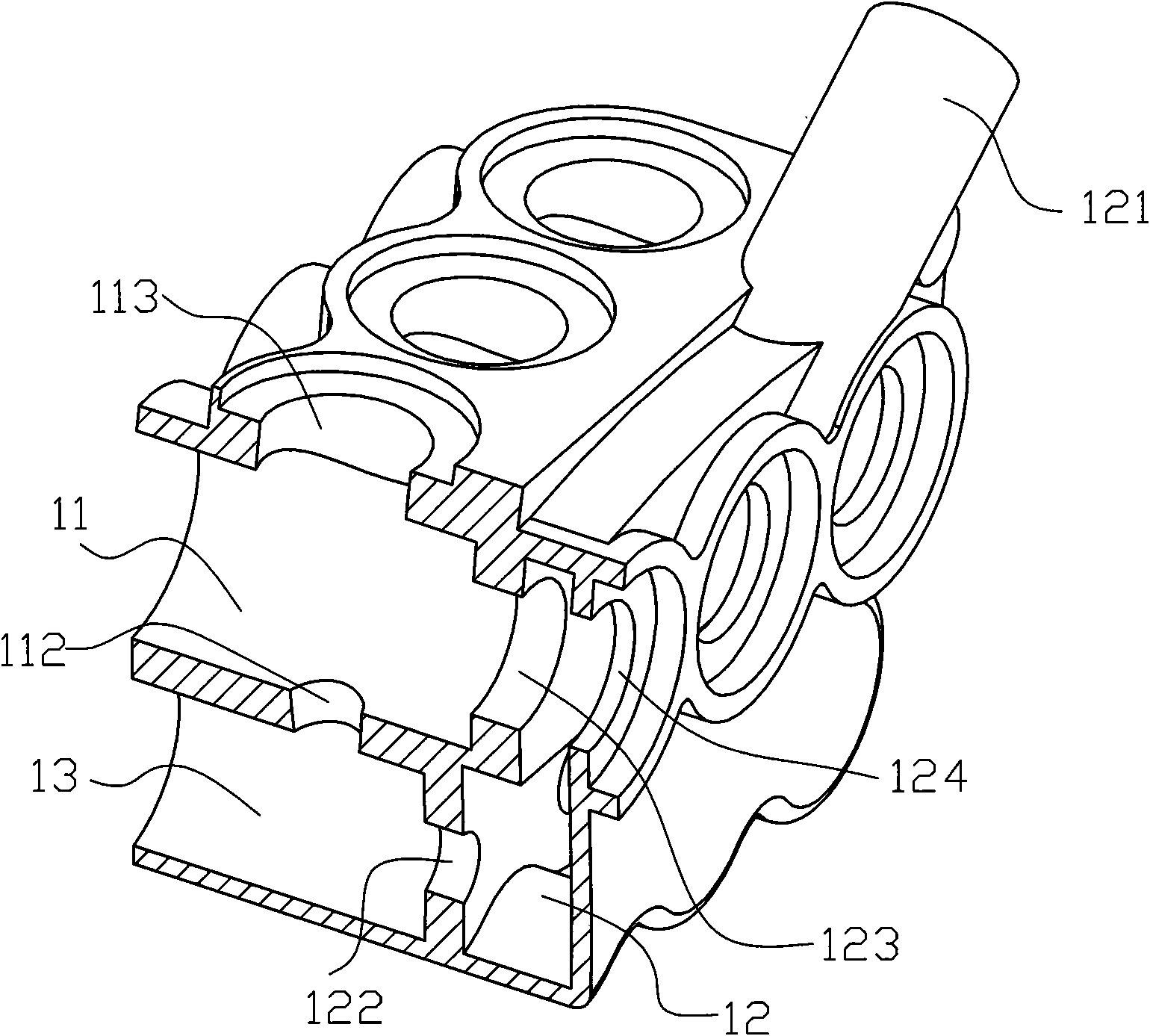

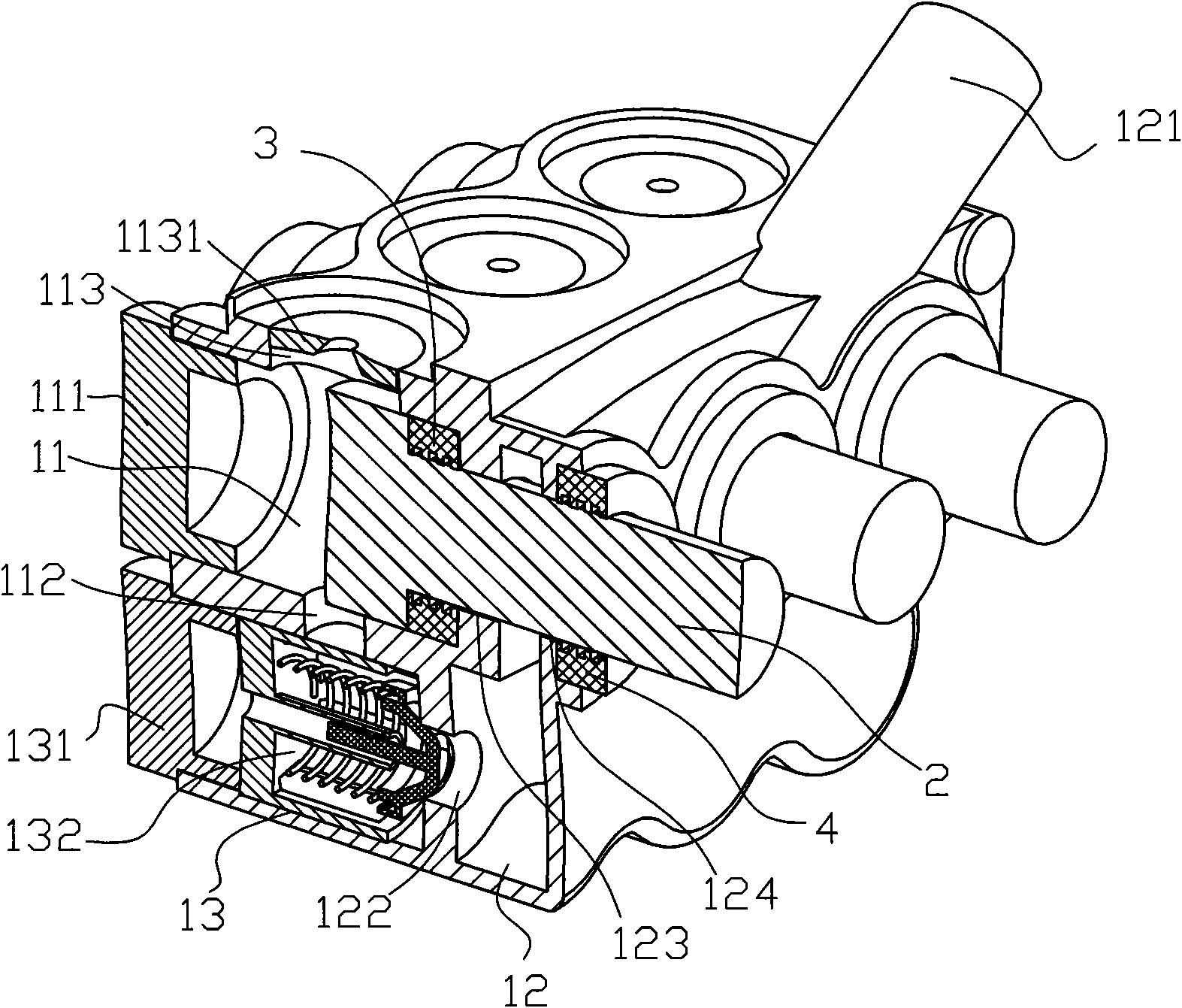

[0016] Such as figure 1 , 2 As shown in and 3, an oil-free lubricated plunger pump includes a valve body 1 and a plunger 2, and the valve body 1 is provided with a plunger chamber 11, a water storage chamber 12 and a water inlet chamber 13.

[0017] The plunger chamber 11 is sealed from the outside world by a plunger cap 111 , and the plunger chamber 11 is provided with a water inlet 112 and a water outlet 113 , wherein a water inlet check valve 1121 is installed on the water inlet 112 .

[0018] The water storage chamber 12 is provided with a water inlet 121 at the top, which is directly used to connect to an external water pipe. The water storage chamber 12 is provided with a communication hole 122 at the bottom to communicate with the water inlet chamber 13. A plunger hole 123 is provided between the cavities 11 , and a plunger installation hole 124 communicating with the outside of the valve body 1 is provided on the outer wall of the water storage chamber 12 .

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com