Setting method for heat pipe start-up temperature value

A start-up temperature and setting method technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problem that the minimum wall temperature of the heat pipe cannot be accurately controlled, achieve considerable economic and social value, simple control, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

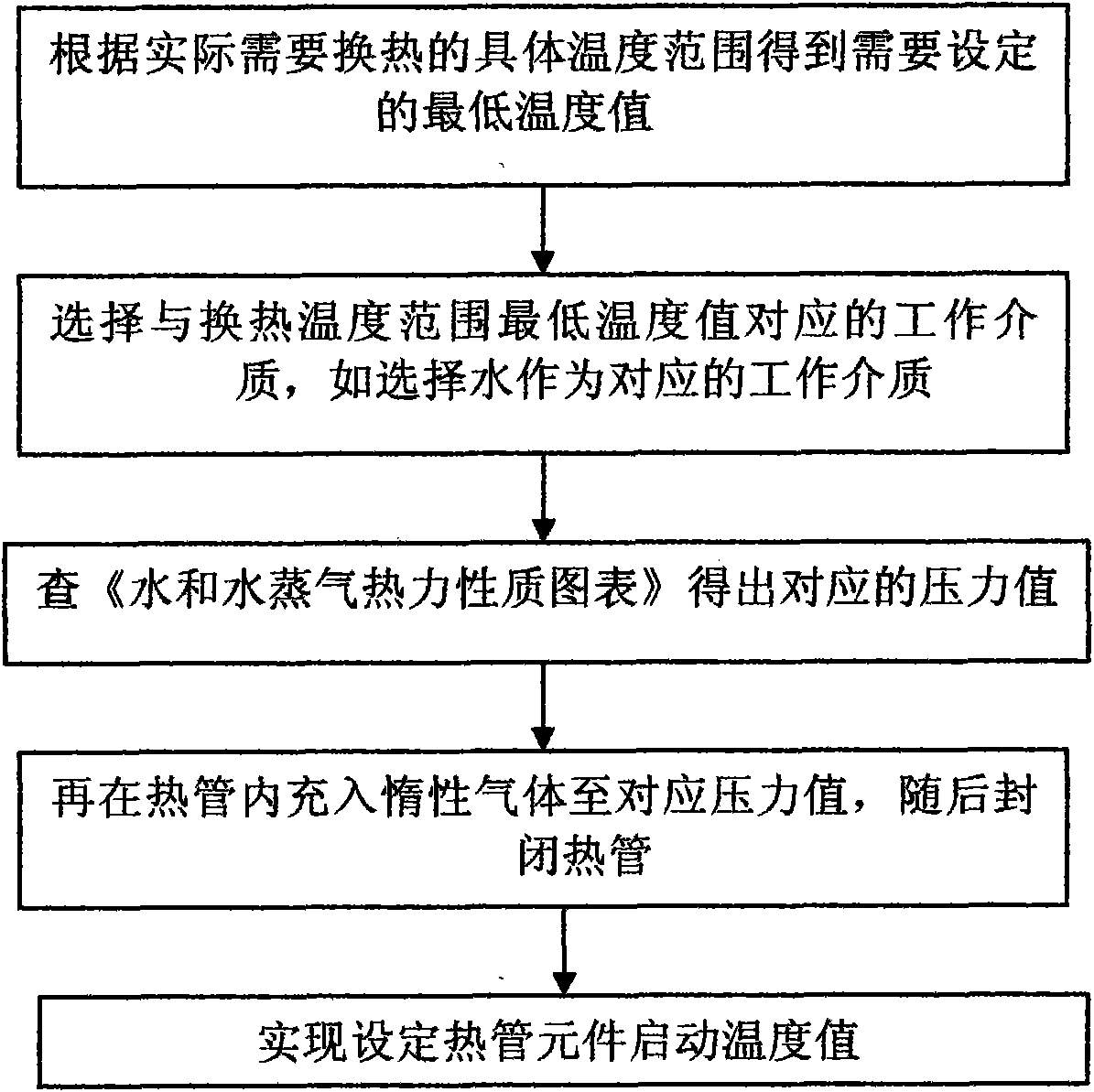

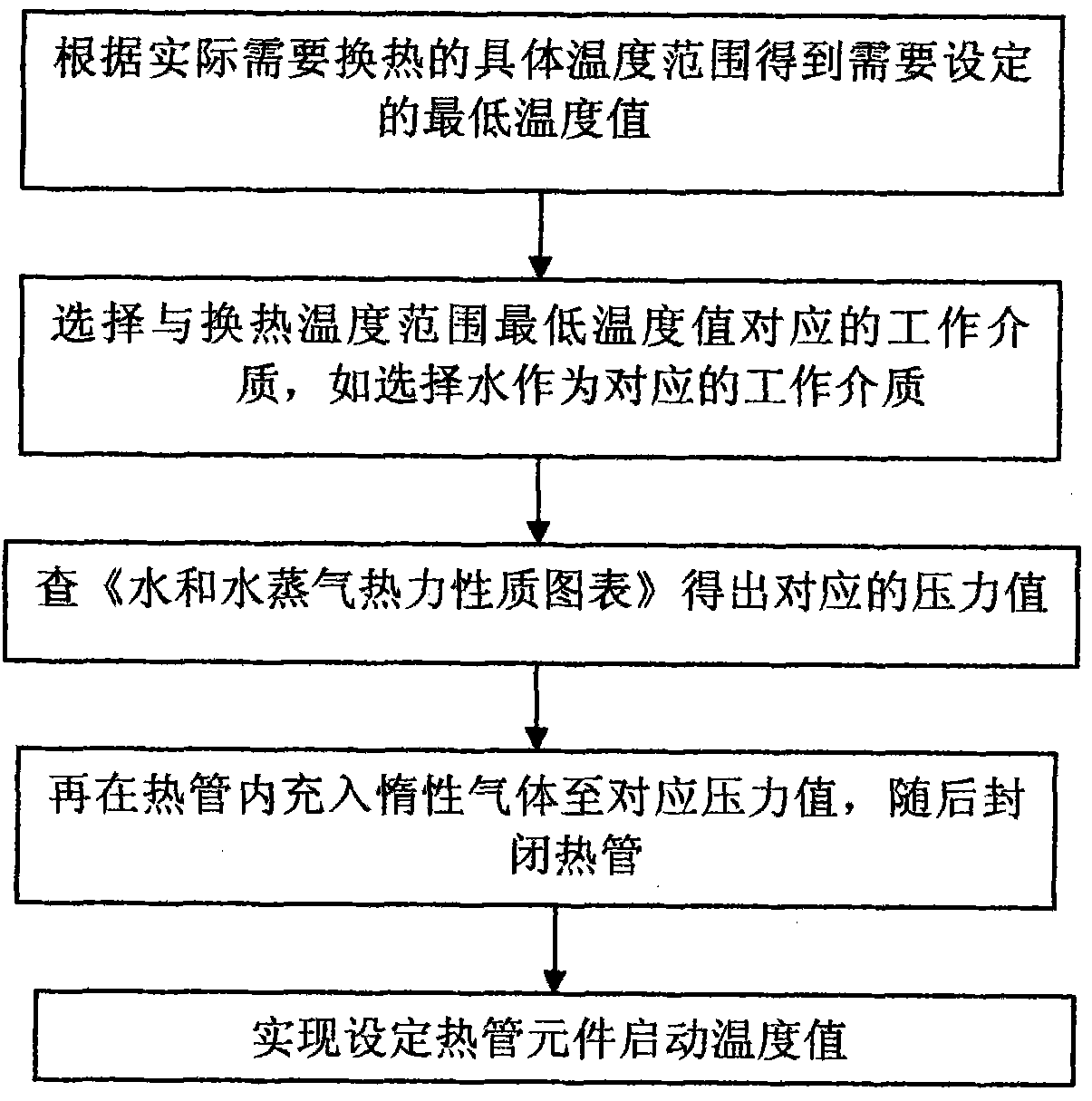

Method used

Image

Examples

Embodiment 1

[0011] The recovery waste heat temperature is above 85°C. It is necessary to set the start-up temperature of the heat pipe to 85°C. Water is selected as the working medium, and the corresponding pressure value is 58KPa absolute pressure by checking the "Chart of Thermal Properties of Water and Water Vapor". After the working medium water is injected into the heat pipe, nitrogen is selected as the inert gas to be charged, and then nitrogen is injected to make the pressure inside the pipe an absolute pressure of 58KPa. The heat pipe made in this way will not exchange heat when the heat exchange temperature is lower than 85°C. up.

Embodiment 2

[0013] The recovery waste heat temperature is above 120°C, the start-up temperature of the heat pipe is 120°C, and water is selected as the working medium, and the corresponding pressure value is obtained as an absolute pressure of 199KPa by checking the "Chart of Thermal Properties of Water and Water Vapor". After the working medium water is injected into the vacuum heat pipe, nitrogen gas is selected as the inert gas to be charged, and then nitrogen gas is injected to make the pressure inside the tube 199KPa absolute. The heat pipe made in this way will not be exchanged when the heat exchange temperature is lower than 120°C. hot.

[0014] The heat pipe made by this method can conveniently control the minimum start-up temperature of the heat pipe, and at the same time control the minimum wall temperature of the heat pipe, exchange heat to the maximum within the required range, and greatly improve the heat exchange efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com