High-power sealed alternating current contactor

An AC contactor, high-power technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of large contact contact pressure and impact resistance requirements, large contact load, etc., to avoid coil heating problems, Reduced coil power consumption and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

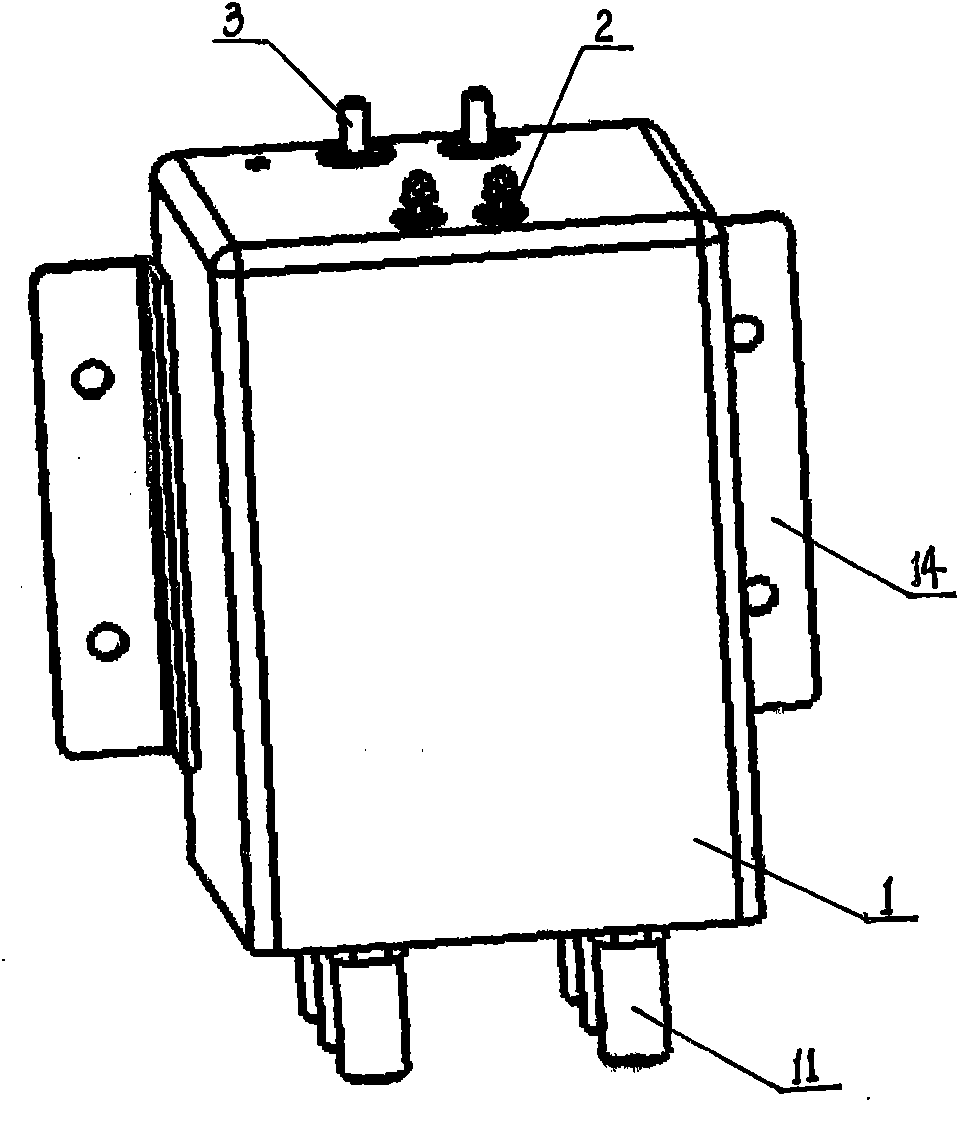

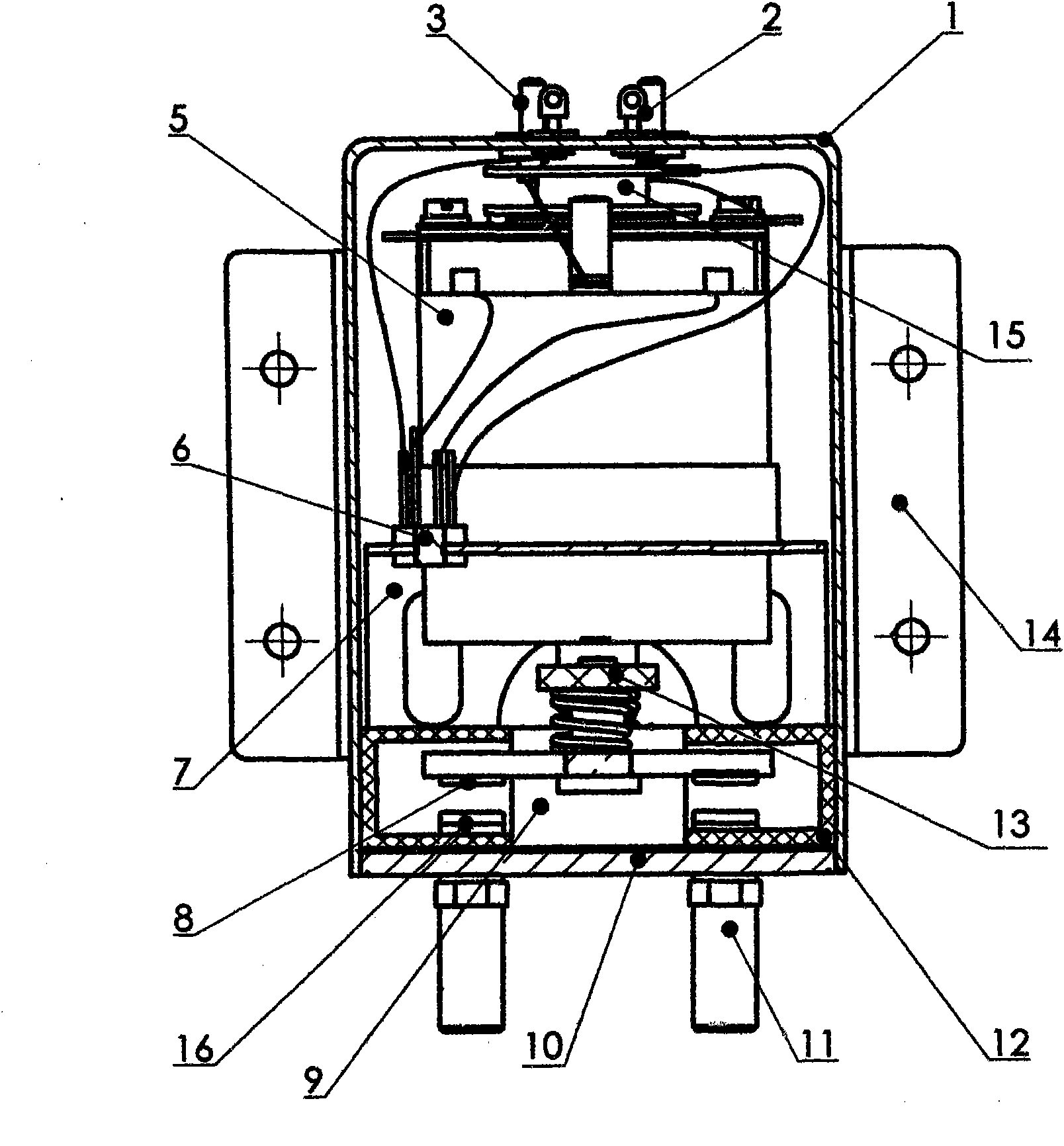

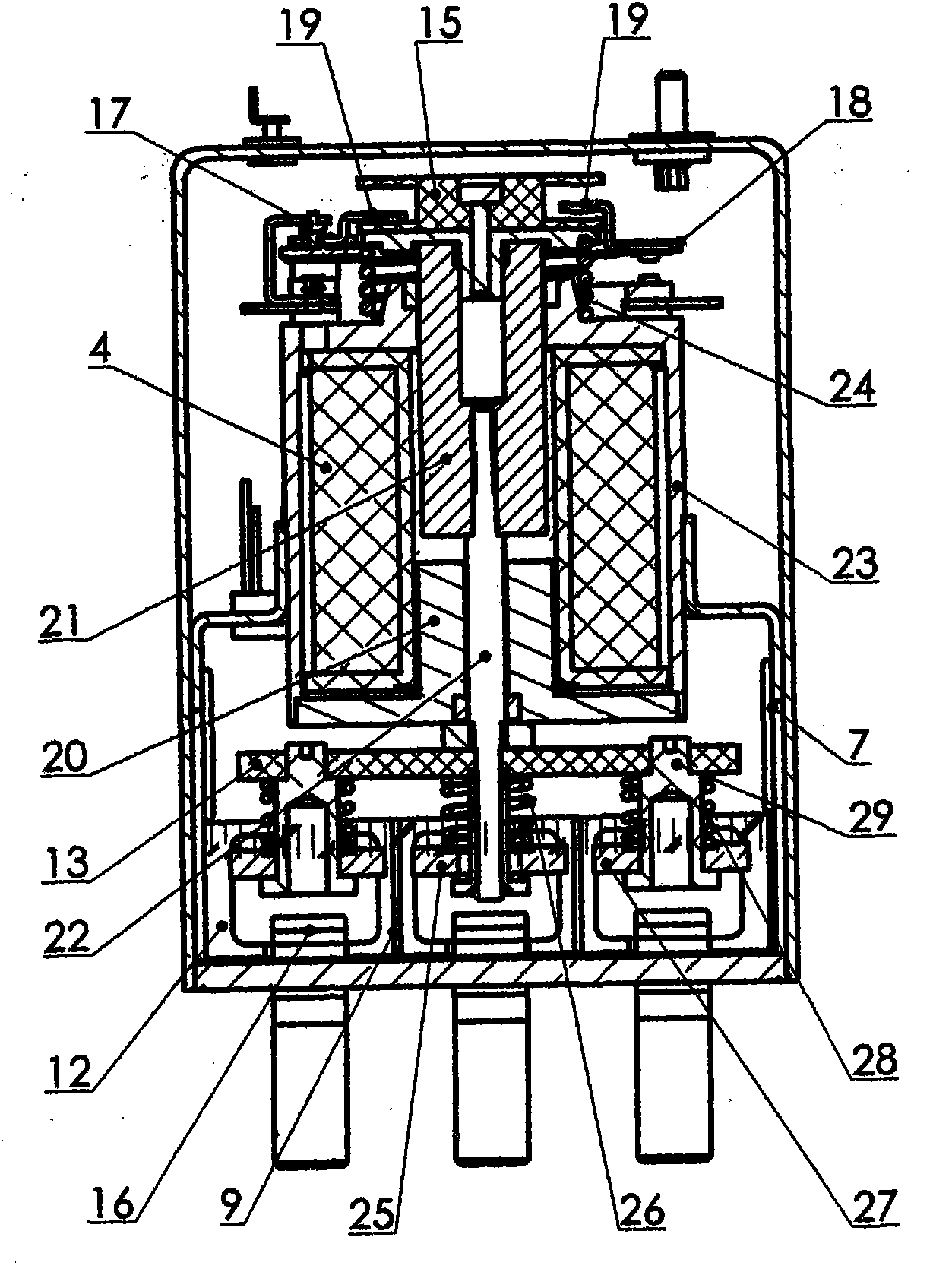

[0020] combined with figure 1 , 2 , 3, 4, 5, 6 describe an embodiment of the present invention.

[0021] A high-power sealed AC contactor, including a housing 1 and a base 10, the housing 1 is fixed on the base 10, and the upper end surface of the housing 1 is sealed and fixed with two input terminals 2 and two auxiliary output terminals 3 through glass insulator sintering, the base 10 are sealed and fixed with six main output terminals 11 through glass insulator sintering, and six main output static contacts 16 fixed on the inner ends of the six main output terminals 11 form three sets of main output static contacts; the suction electromagnetic mechanism 5 passes through The bracket 7 is fixed on the base 10 and is located in the middle of the housing 1, and the rectifying component 6 is fixed on the bracket 7; the suction electromagnetic mechanism 5 is composed of a double coil 4, a pole shoe 20, a moving iron core 21, a linkage shaft 22 and a housing 23, the double coil 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com