Method for converting thermal energy at a low temperature into thermal energy at a relatively high temperature by means of mechanical energy, and vice versa

A thermal energy conversion and reverse conversion technology, which is applied to compressors, refrigerators, lighting and heating equipment, etc., can solve the problems of poor efficiency of compressors and decompression units, and achieve the effect of improving power factor or efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

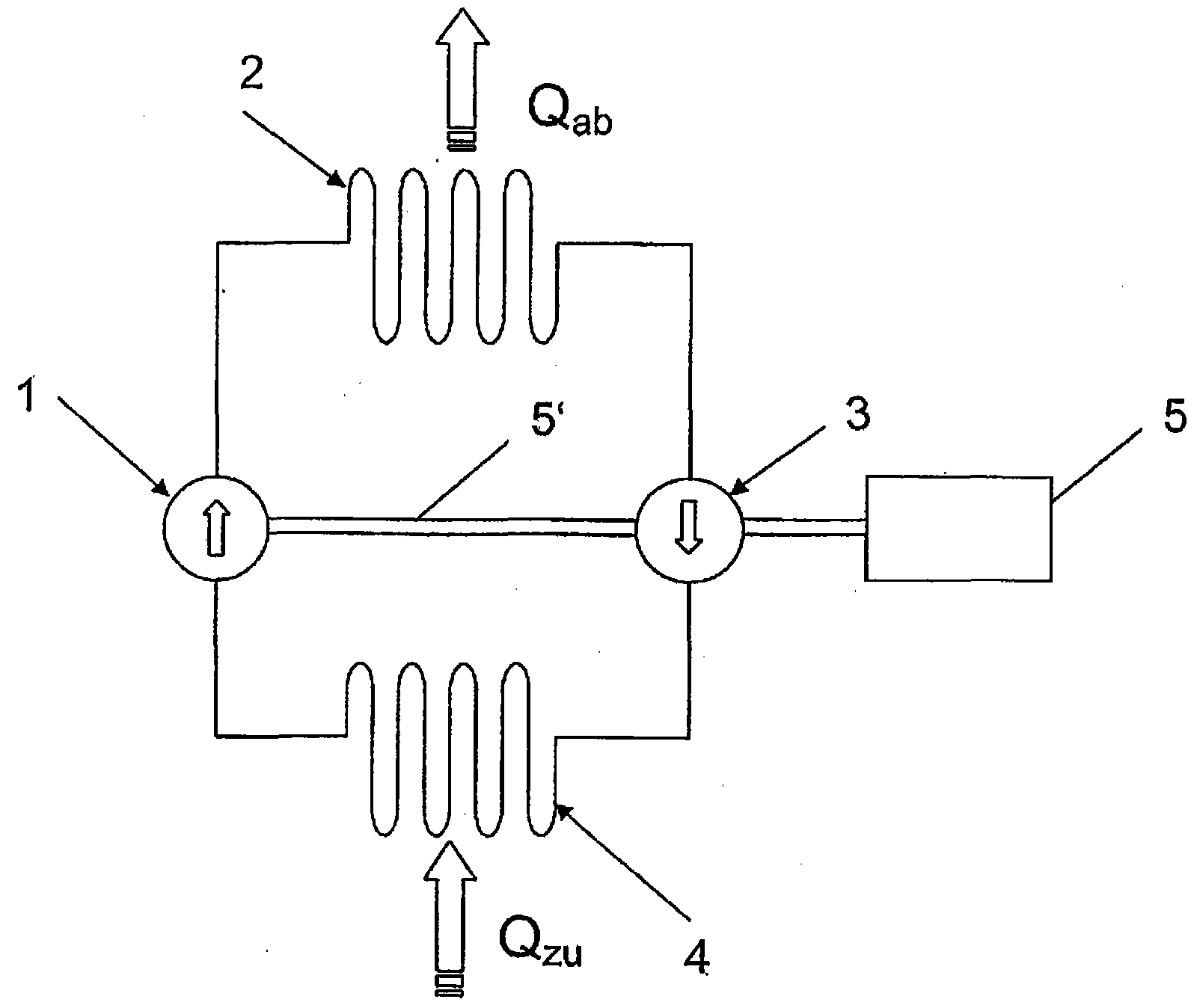

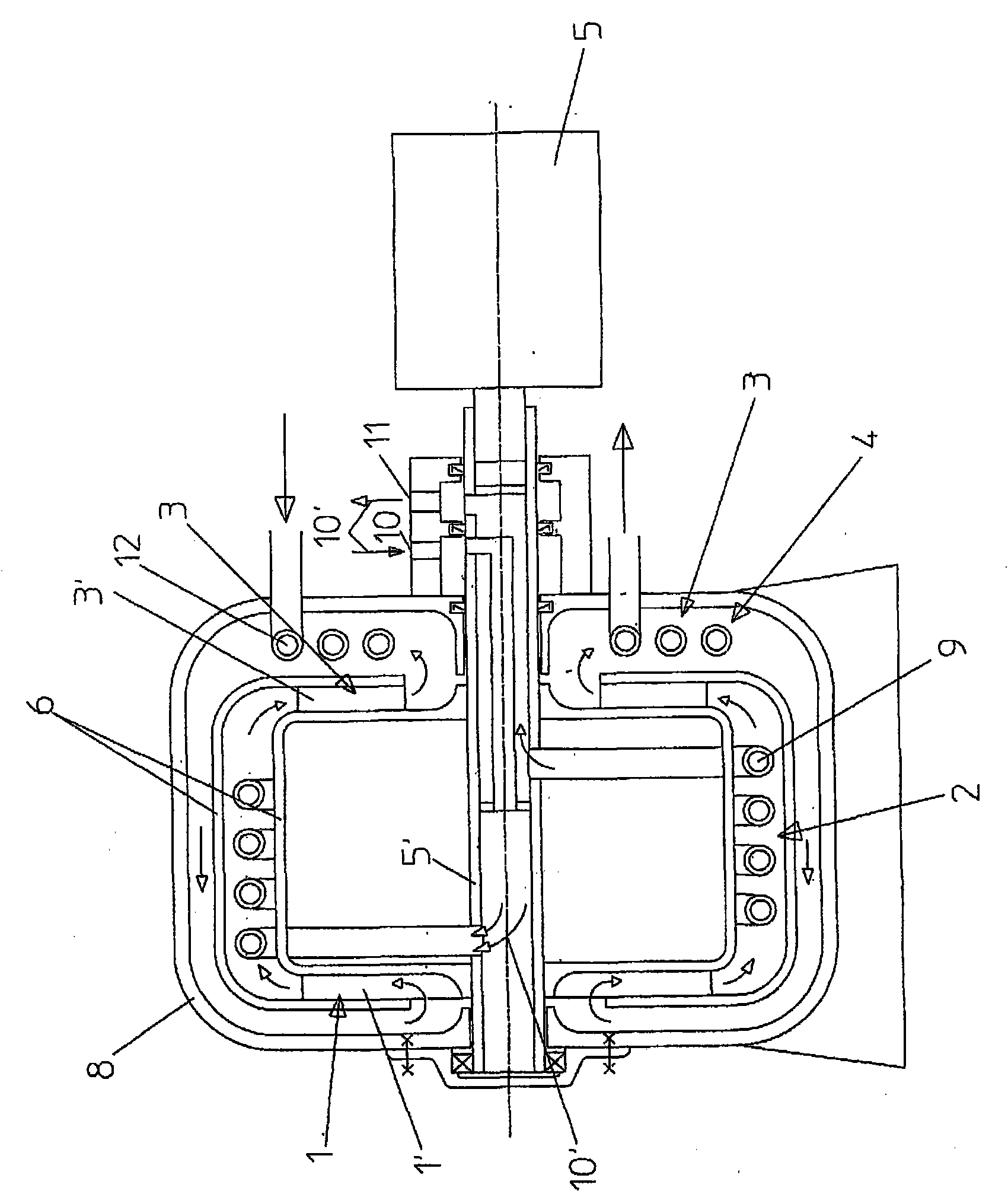

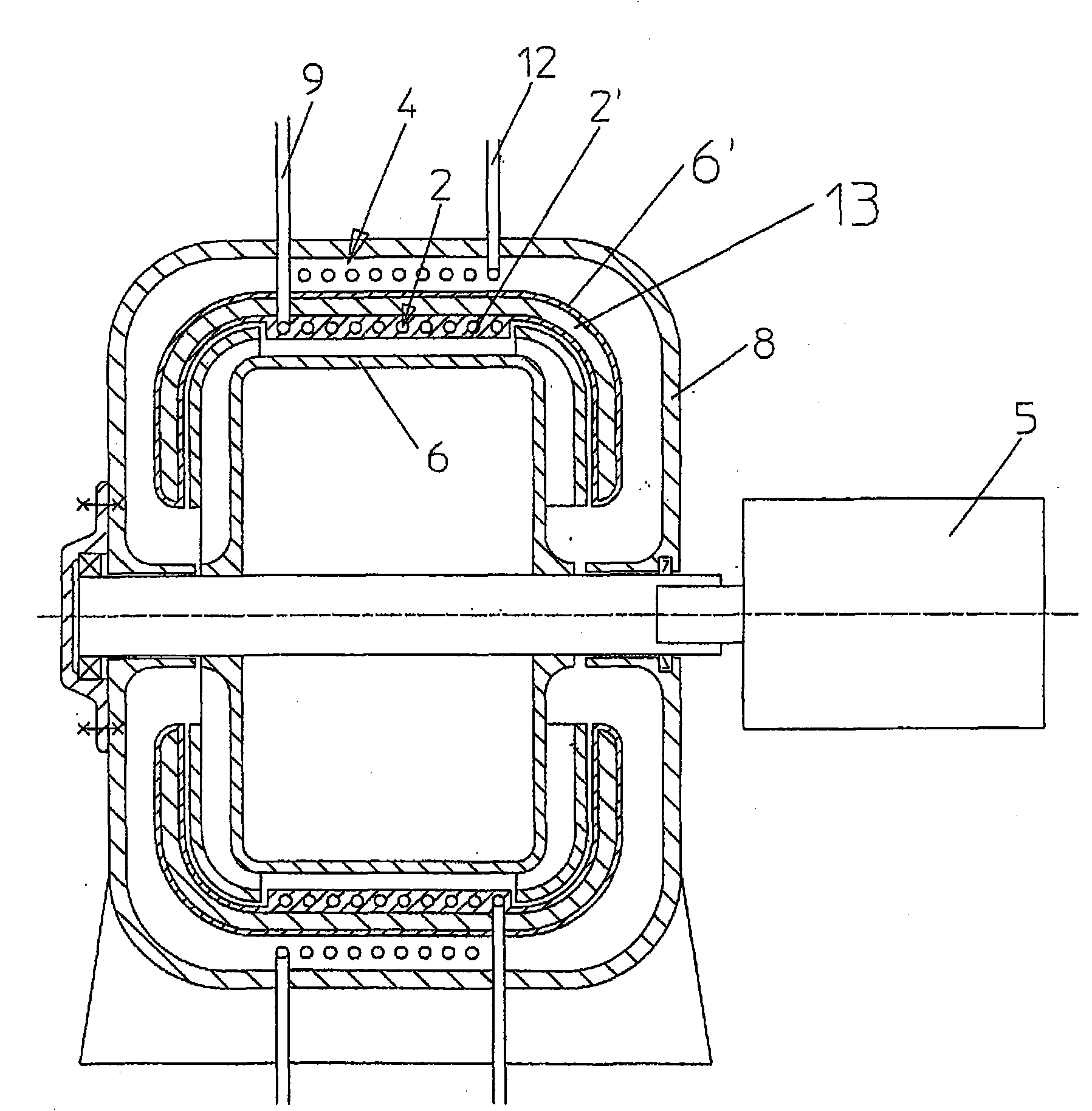

[0048] figure 1 A schematic process block diagram of a thermodynamic cycle process as known in principle from the prior art is shown. When used as a heat pump as shown, the gaseous working medium is firstly compressed isentropically by means of the compressor 1 . Then, isobaric heat dissipation is carried out through the heat exchanger 2, so that the heat energy with a very high temperature is released to the heating circuit through the circuit (water, water / antifreeze or other liquid heat transfer medium).

[0049] An isentropic decompression is then carried out in a decompression unit 3 designed as a turbine, whereby the mechanical energy is recovered. An isobaric heat supply is then carried out via a further heat exchanger 4 , whereby low-temperature thermal energy is fed to the system via a circuit (water, water / antifreeze, brine or another liquid heat transfer medium). In this case, thermal energy is usually supplied from well water from so-called depth probes, for whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com