Humidifying microwave sterilization method of coarse powder of health pill prescription medicinal material

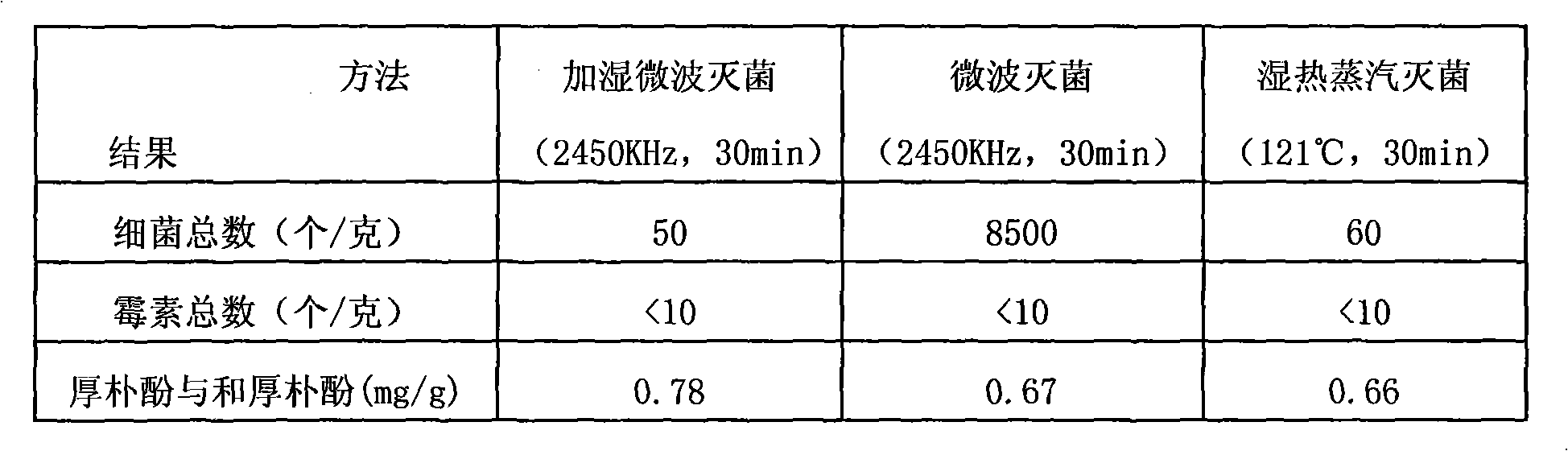

A technology of microwave sterilization and Baoji pills, applied in the direction of irradiation, etc., can solve the problems affecting the stability of Chinese patent medicine product quality, strict implementation of energy saving and consumption reduction, loss of volatile components and heat-sensitive components of medicinal materials, and inability to use large-scale production of traditional Chinese medicine and other problems, to achieve the effect of improved production environment, good sterilization effect, efficient and stable sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

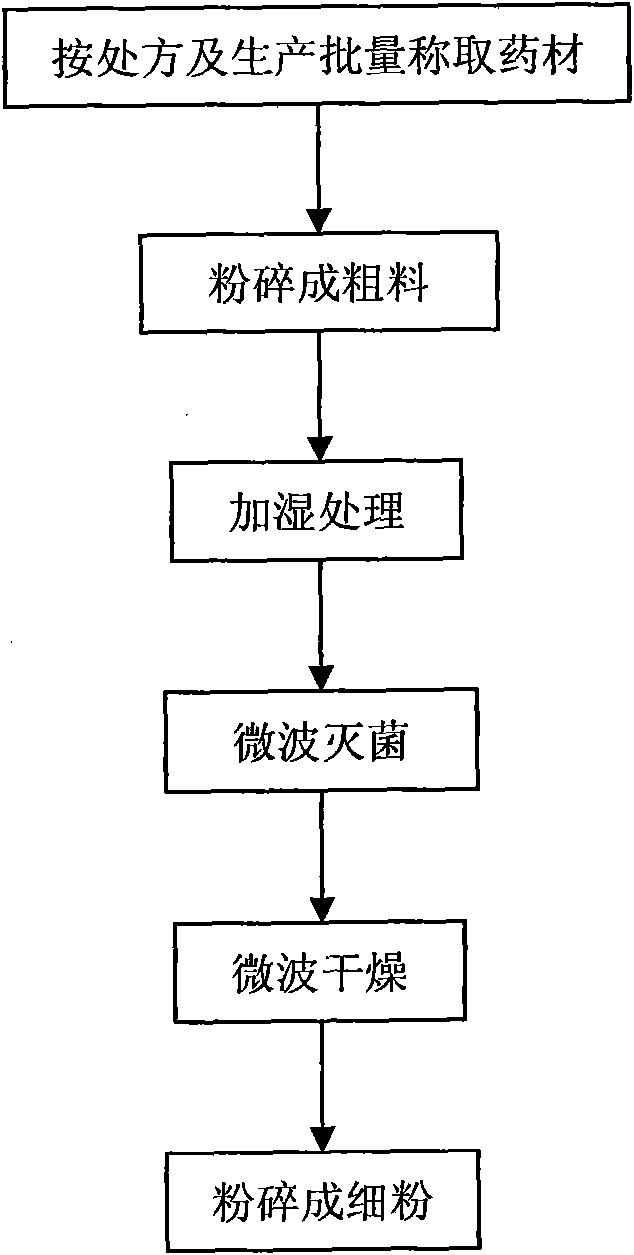

Method used

Image

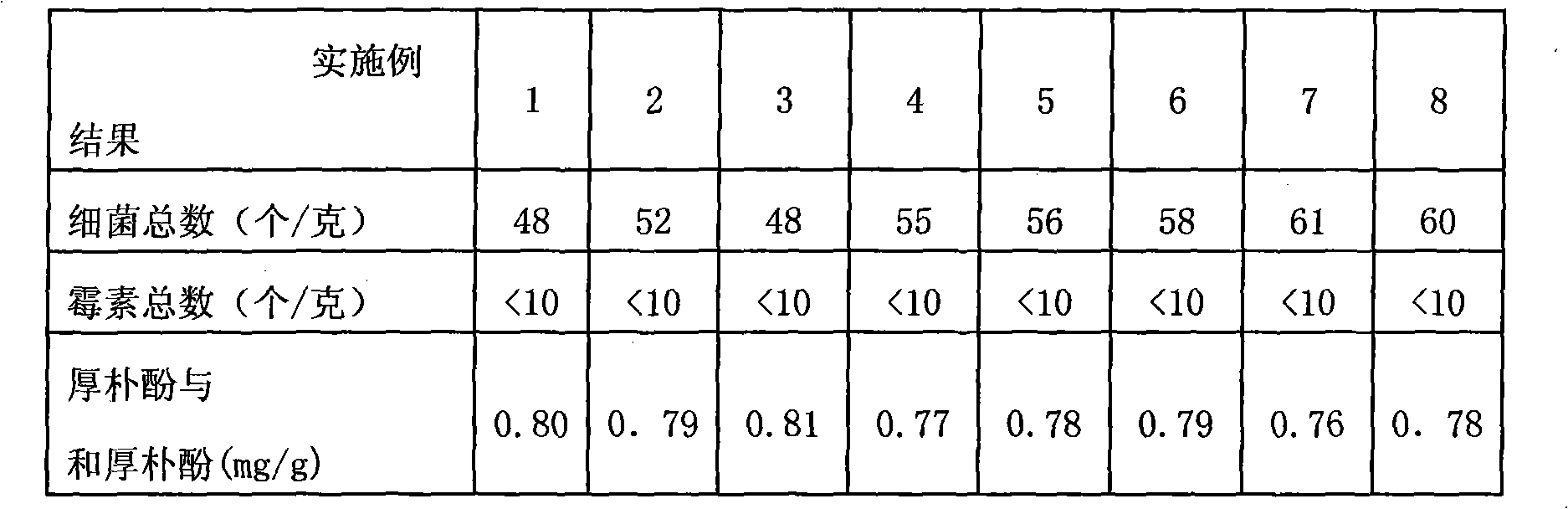

Examples

Embodiment 1

[0030] Receive 300 kilograms of prescription medicinal materials according to the production batch, and crush all the medicinal materials into coarse powder that passes through the No. 2 sieve; then pour them into a humidifying tank with stirring, and add water by pressurized spraying, and the amount of water added is 8% of the weight of the medicinal materials, that is, 24 When adding water, stir the coarse powder of medicinal materials. After adding water and stirring evenly, stop stirring and let it stand for 5 minutes; then take out the wet medicinal materials and put them into the feeding device of the microwave sterilization equipment, and use the feeding device to feed the coarse powder of medicinal materials Lay it on the conveyor belt, and send it to the microwave sterilization tunnel for sterilization through the material sorting device. The processing conditions are: the thickness of the medicinal materials is controlled at about 3cm, the conveying speed of the convey...

Embodiment 2

[0032]Receive 300 kilograms of prescription medicinal materials according to the production batch, and crush the medicinal materials into coarse powder that passes through the No. 2 sieve; then pour them into a humidifying tank with stirring, and add water by pressurized spraying, and the amount of water added is 9% of the weight of the medicinal materials, that is, 27 When adding water, stir the coarse powder of medicinal materials, stop stirring after adding water and let it stand for 8 minutes; then take out the wet medicinal materials and put them in the feeding device of the microwave sterilization equipment, and lay the coarse powder of medicinal materials on the conveyor through the feeding device On the belt, it is sent to the microwave sterilization tunnel through the material sorting device for sterilization treatment. The treatment conditions are: the thickness of the medicinal materials is controlled at about 5cm, the conveying speed of the conveyor belt is adjusted ...

Embodiment 3

[0034] Receive 300 kg of prescription medicinal materials according to the production batch, crush all the medicinal materials into coarse powder that passes through the No. 2 sieve; then pour them into a humidifying tank with stirring, add water by pressurized spraying, and the amount of water added is 10% of the weight of the medicinal materials, that is, 30 When adding water, stir the coarse powder of medicinal materials, stop stirring after adding water and let it stand for 12 minutes; then take out the wet medicinal materials and put them in the feeding device of the microwave sterilization equipment, and lay the coarse powder of medicinal materials on the conveyor through the feeding device On the belt, it is sent to the microwave sterilization tunnel through the material sorting device for sterilization treatment. The treatment conditions are: the thickness of the medicinal materials is controlled at about 6cm, the conveying speed of the conveyor belt is adjusted to 0.28m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap