Gearbox-driven vacuum braking device

A technology of vacuum braking and transmission, applied in the direction of braking transmission, auxiliary driving device, control device, etc., it can solve the problem that the vacuum supplements too slow braking performance, affects the braking effect of the car, and cannot meet the requirements of the braking system, etc. problems, to achieve the effect of convenient and flexible installation, simple and reasonable structure, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

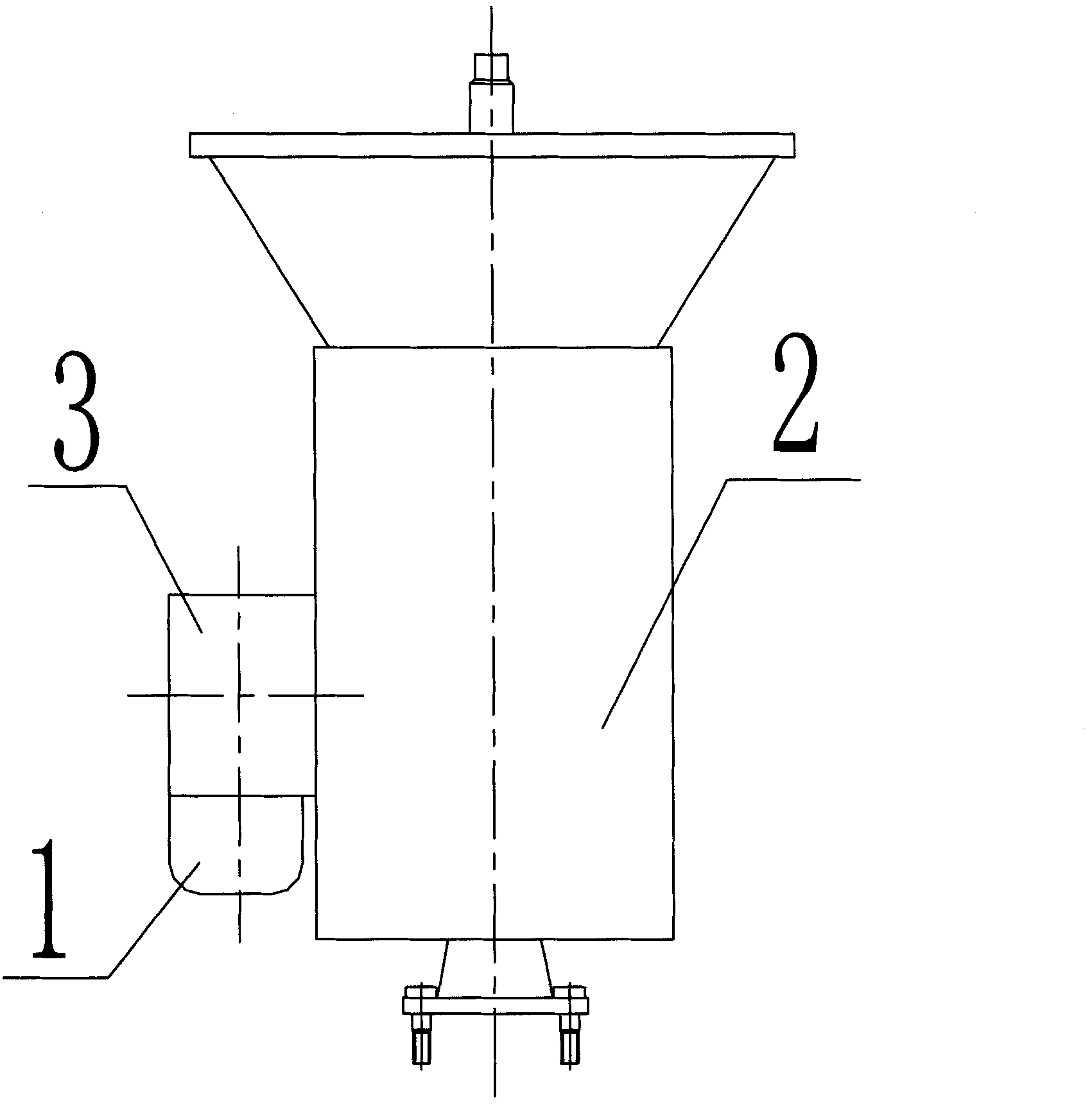

[0014] Embodiment 1: A vacuum brake device driven by a gearbox, such as figure 1 As shown, it includes a vacuum pump 1, a gearbox 2, and an adapter box 3 connecting the vacuum pump 1 and the gearbox 2. The vacuum pump 1 and the adapter box 3 are installed on the left side of the gearbox 2. The adapter box 3 is meshed with the gear of the gearbox 2 through gears. The vacuum pump 1 is independently installed behind the adapter box 3 .

Embodiment 2

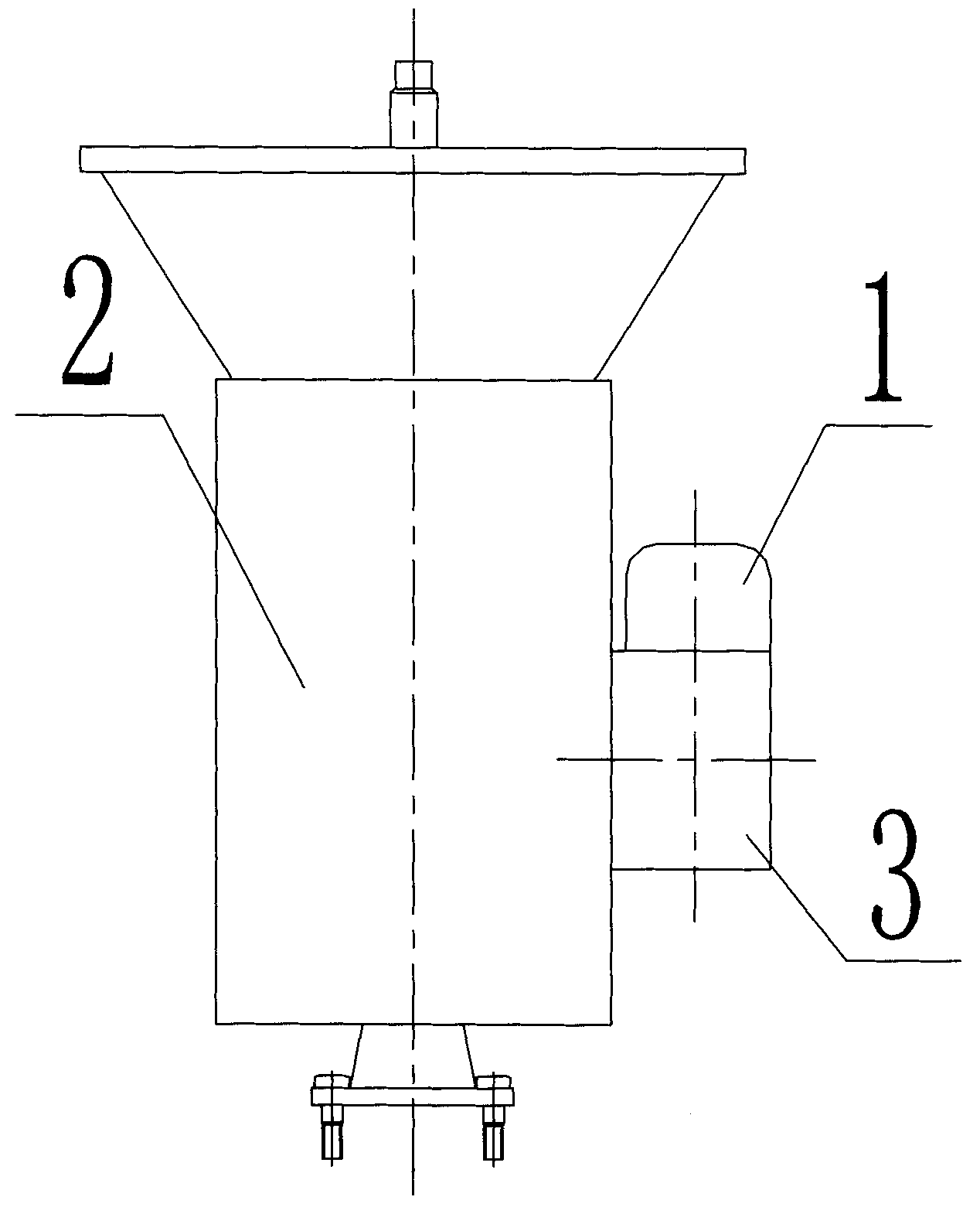

[0015] Embodiment 2: A vacuum brake device driven by a gearbox, such as figure 2 As shown, it includes a vacuum pump 1, a gearbox 2, and an adapter box 3 connecting the vacuum pump 1 and the gearbox 2. The vacuum pump 1 and the adapter box 3 are installed on the power take-off port on the right side of the gearbox 2. The adapter box 3 is meshed with the gear of the gearbox 2 through gears. The vacuum pump 1 is independently installed in front of the junction box 3 .

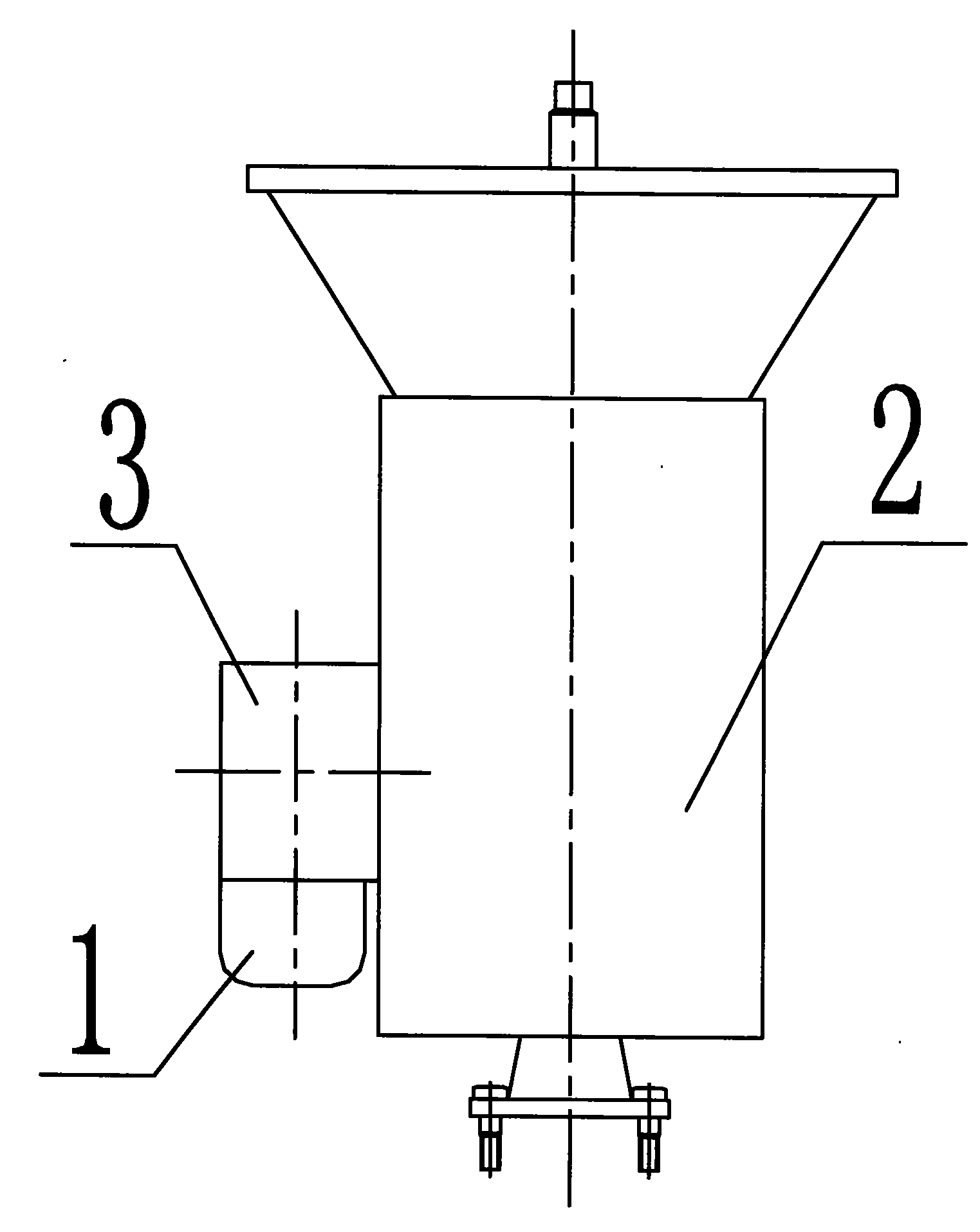

[0016] In the above embodiment, the vacuum pump 1 and the adapter box 3 can also be installed on the upper or lower power outlet of the gearbox 2 according to the position of the power outlet of the gearbox 2, and the adapter box 3 and The vacuum pump 1 can also be integrated and installed on the gearbox 2 as a whole. The vacuum pump 1 is provided with an independent lubricating oil path for lubrication, or the lubricating oil path of the vacuum pump 1 communicates with the lubricating oil path of the engine f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com