Carbonation depth detector

A carbonization depth and detection instrument technology, applied in the direction of measuring instrument components, instruments, measuring devices, etc., can solve the problems of difficulty in determining the carbonization front, poor light in the hole, difficult positioning, etc., to eliminate insufficient light in deep holes and direct readings , Measuring the effect of quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

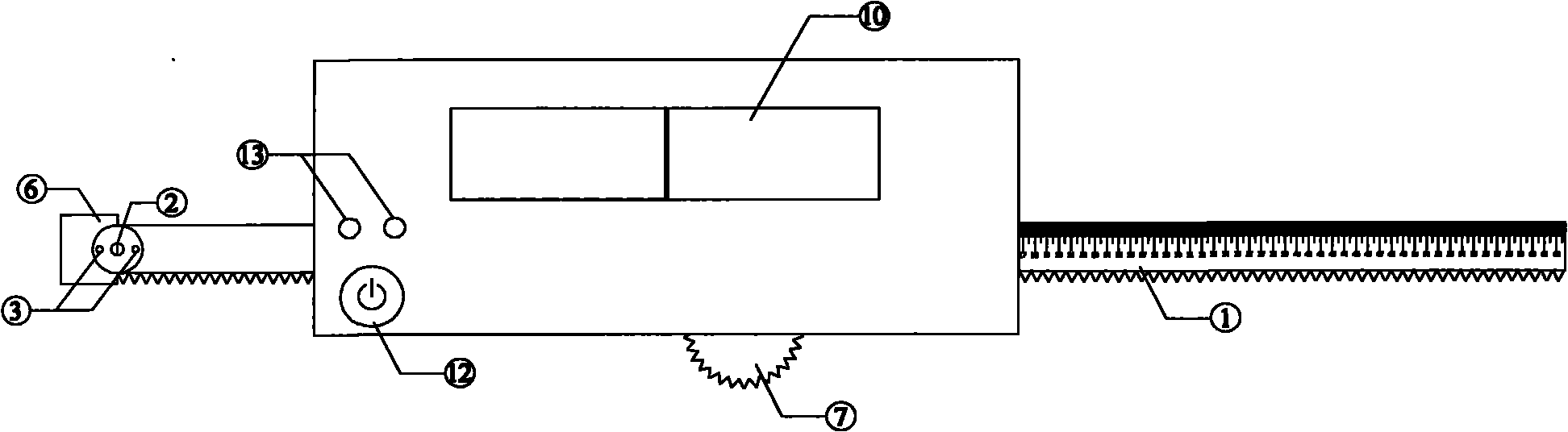

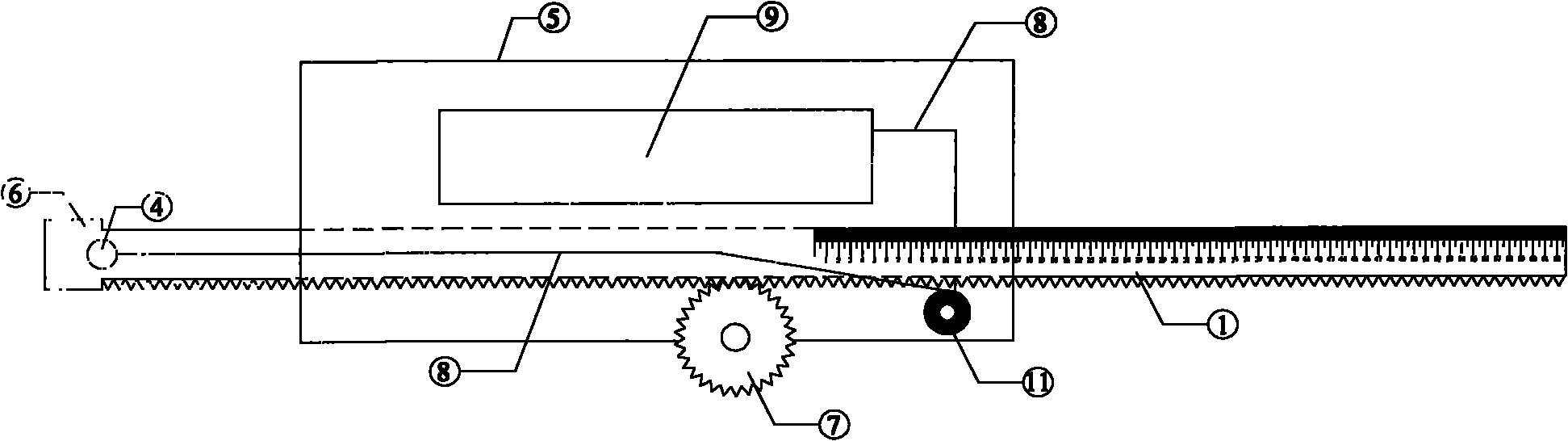

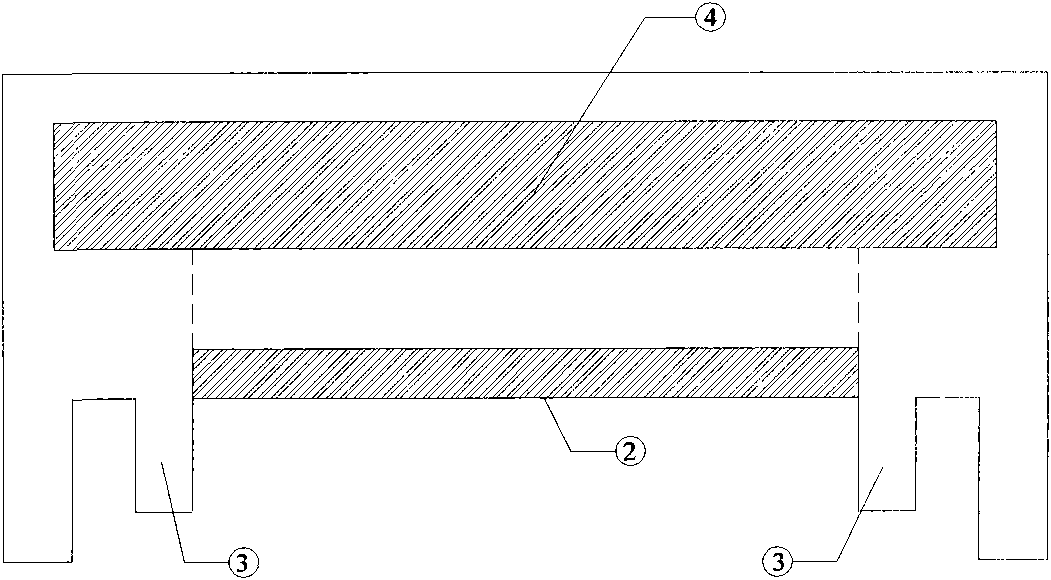

[0012] The measurement of carbonization depth is mainly composed of image magnification and imaging module and measurement module. The image magnification and imaging module mainly includes several parts such as image magnification, image acquisition and transmission, and image display. The image magnification function is mainly realized by an optical lens or a microscope lens with a magnification function; image acquisition and transmission are mainly realized by lighting sources, cameras, signal cables, and image acquisition and processing chips; image display is the acquisition and processing of video signals Input the video monitor to display the captured image information in real time. Through the image magnification and imaging module, the color change image of the carbonized area and the non-carbonized area of cement-based materials such as concrete sprayed with phenolphthalein can be clearly displayed on the video display screen. The carbonization depth measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com